Bare terminal protection mechanism of power line

A technology of bare wire terminal and protection mechanism, which is applied in the field of protection mechanism of power line bare wire terminal, which can solve the problems of easy damage, clamping by shear force, and easy falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

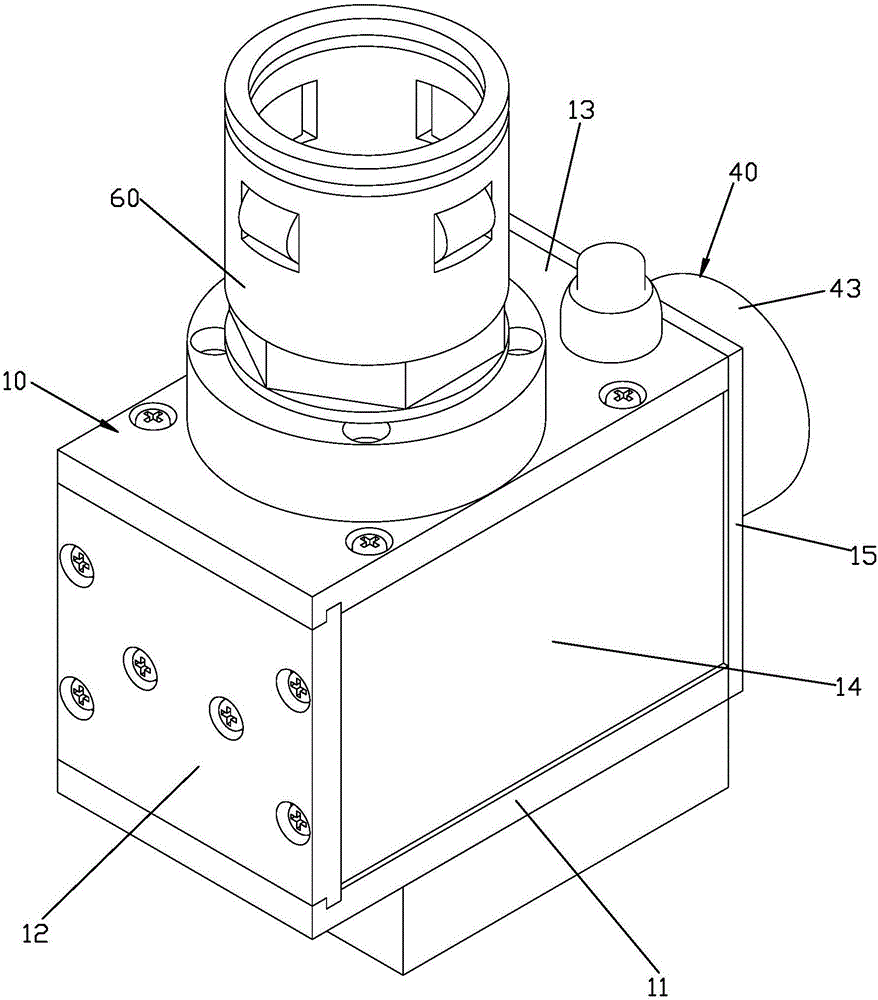

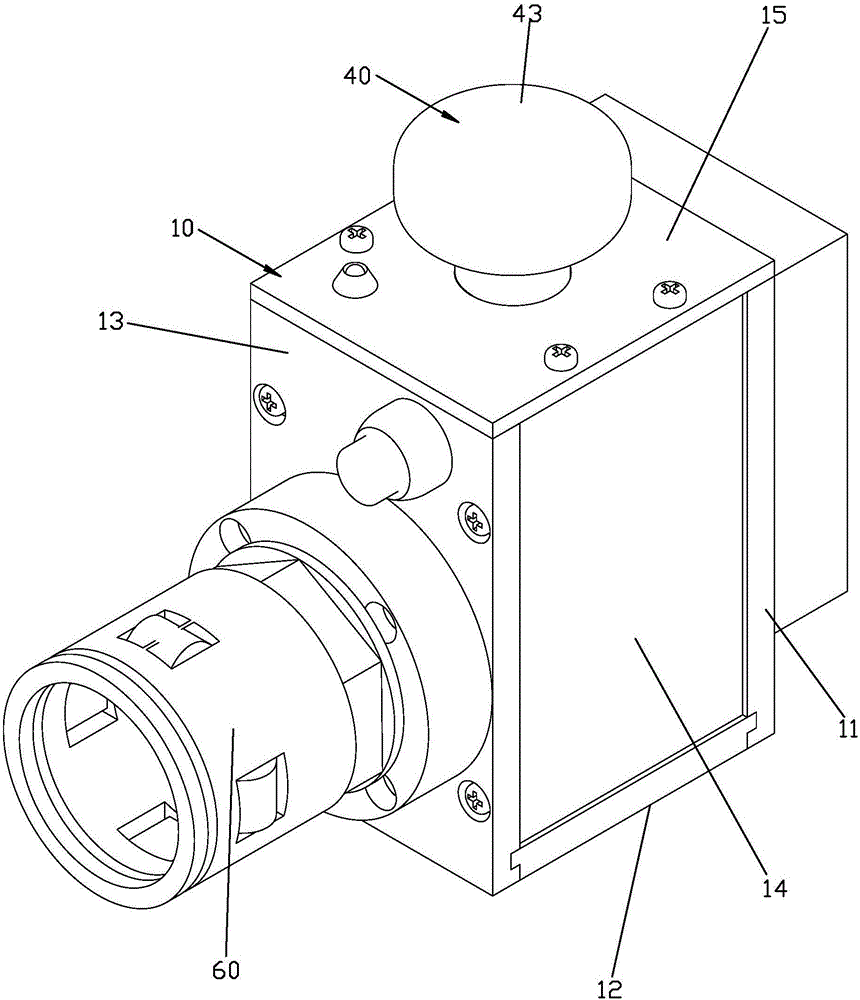

[0028] Please check Figure 1 to Figure 8 , The power cord bare wire terminal protection mechanism includes a solid base 10 , a clamping fastening block 20 , a clamping moving block 30 , an operating member 40 and an elastic body 50 .

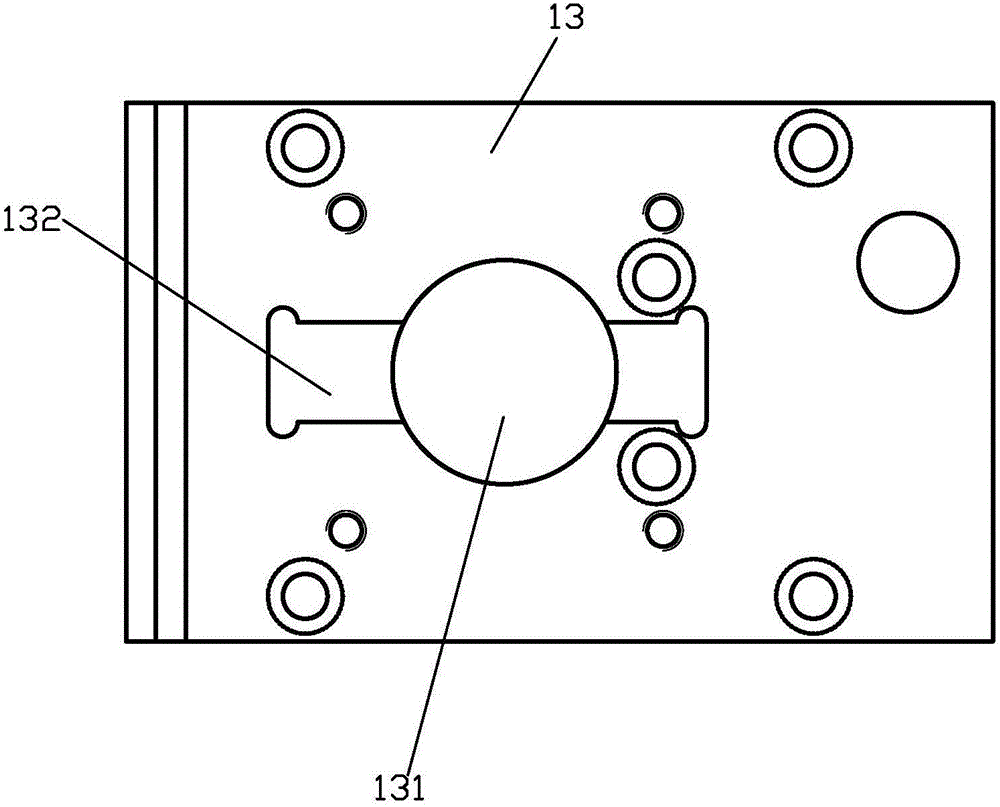

[0029] The fixing base 10 includes a bottom plate 11 , a rear plate 12 , an upper cover plate 13 and two side plates 14 . The back plate 12 is fixed on the bottom plate 11, the two side plates 14 are spaced left and right and fixed on the bottom plate 11, the rear sides of the two side plates 14 are fixed on the back plate 12, and the upper cover plate 13 is fixed on the bottom plate 11. The top surface of the rear panel 12 and the side panels 14.

[0030] The clamping block 20 is affixed to the fixed seat 10. In the specific structure: the clamping block 20 is affixed between the bottom plate 11 and the upper cover plate 13, and the clamping block 20 is interposed between the two side plates 14 , There is a gap between the clamping block 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com