A safety control method for radio welding machine

A safety control and radio technology, applied in safety/protection circuits, collectors, electric vehicles, etc., can solve problems such as the inability to guarantee the safety and efficiency of lithium-ion batteries, the inability to supply power through the mains, and the inability to meet safety needs, etc., to prevent Injury, protection and safety, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

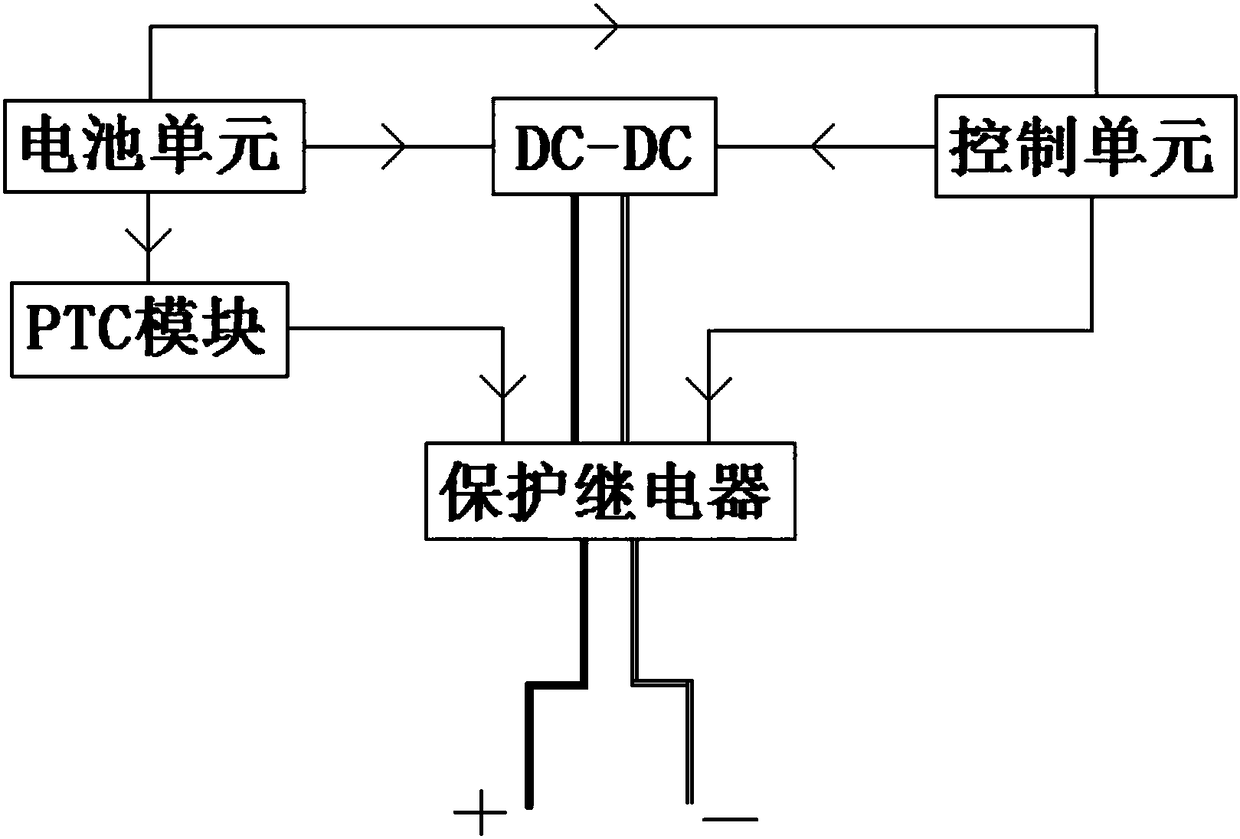

[0022] like figure 1 As shown, a safety control method for a wireless welding machine includes a battery pack unit for providing direct current, the battery pack unit is connected to a DC-DC module, and the DC-DC module is used to connect the battery pack The direct current output by the unit is converted into the required voltage value, and the output of the DC-DC module is connected to the positive terminal and the negative terminal, including the following control steps:

[0023] 1) The electrical switch is closed, and the control unit monitors the voltage parameter value of the battery unit to determine whether the voltage is within the safe discharge voltage range; if it is within the range, send an instruction to the discharge relay to make the control port S1 of the discharge relay true;

[0024] 2) The PTC module monitors the internal temperature value of the battery unit through the PTC resistance, and judges whether the temperature value is within the safe temperatur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap