Magnetic eddy current safety speed coupler

A magnetic eddy current and coupler technology, which is applied in the field of couplers, can solve the problems of easy demagnetization of magnets, product scrapping, and reduced product life, and achieve the effects of eliminating unstable factors, short maintenance time, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

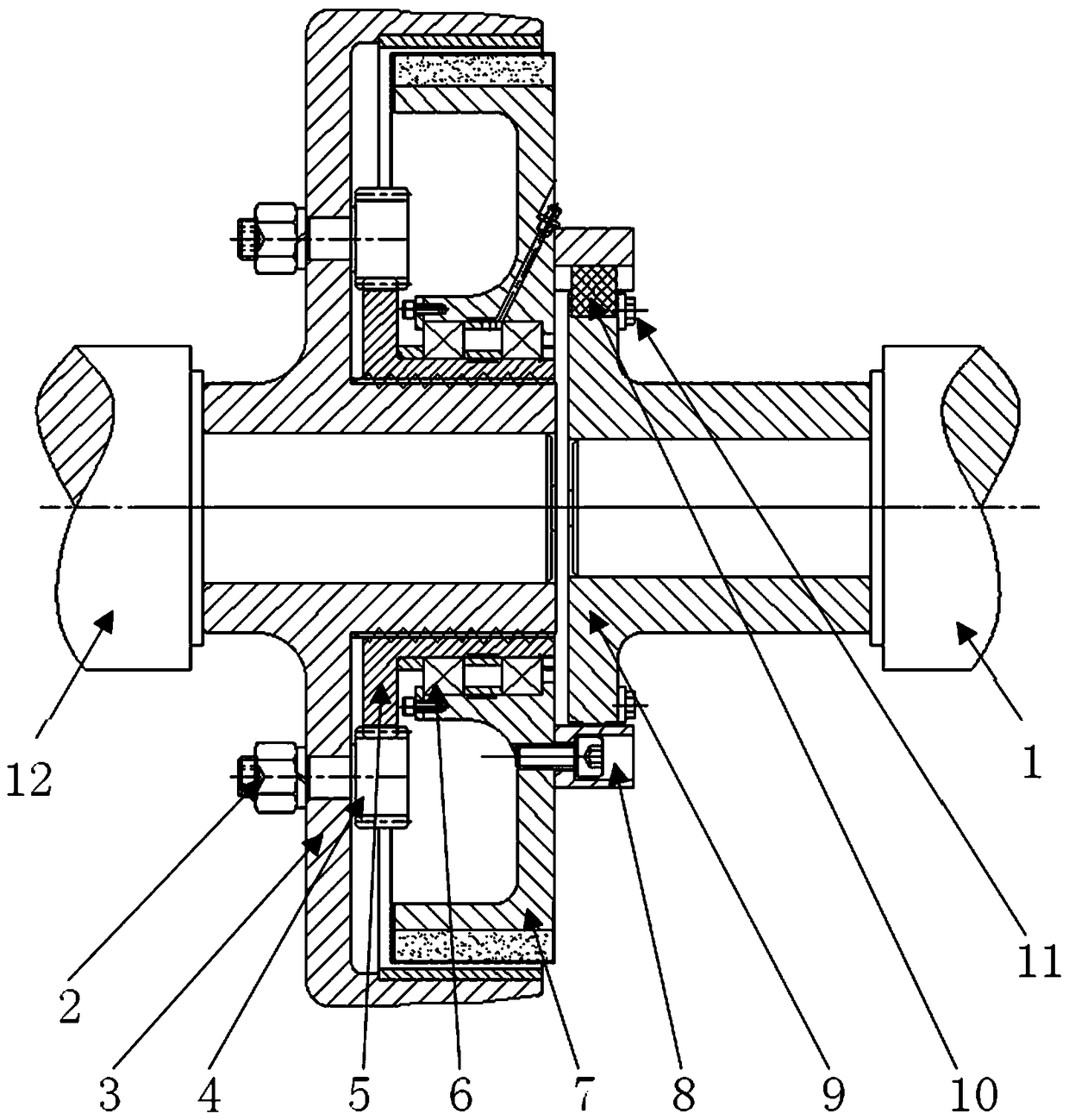

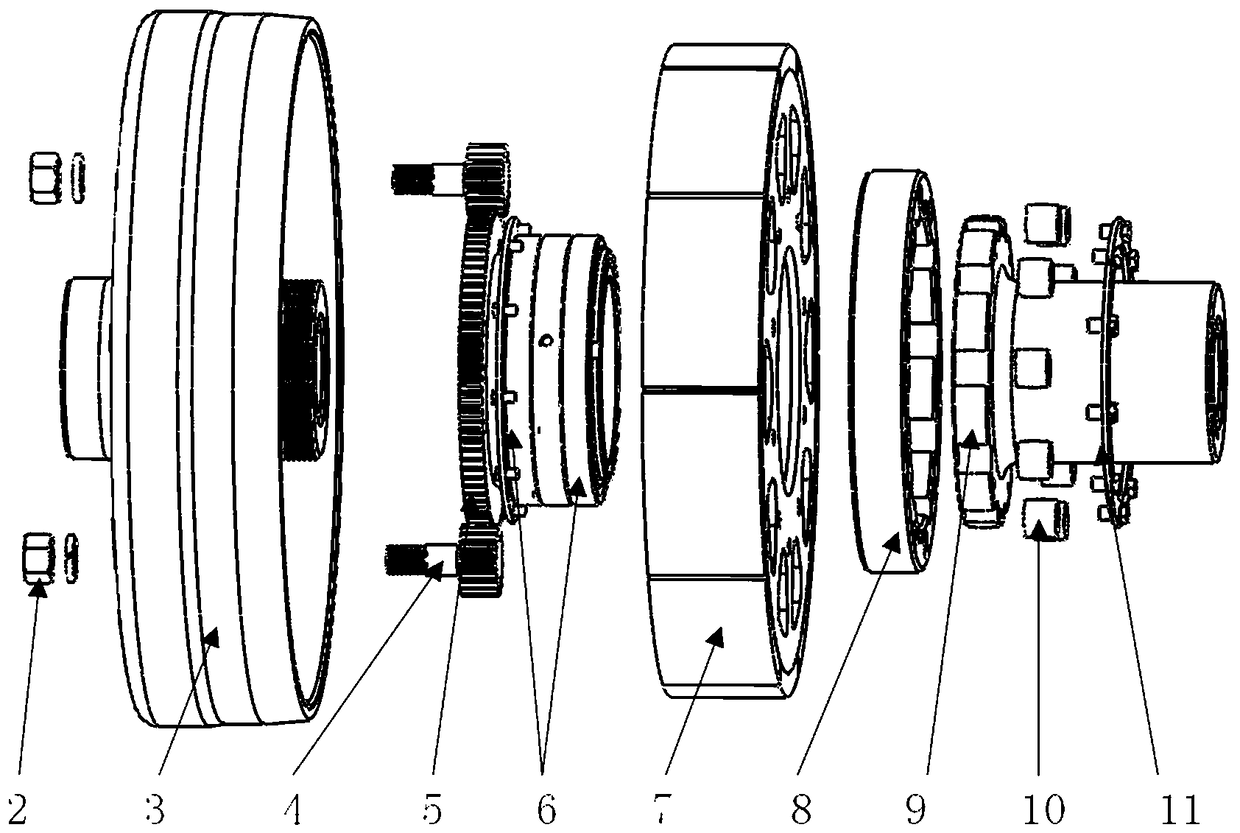

[0038] The magnetic eddy current safety speed-regulating coupler includes a motor connecting shaft 12, an outer rotor 3, an inner rotor 7, and a driven shaft 1. The motor connecting shaft 12 is integrated with the outer rotor 3, and the inner rotor 7 is integrated with the driven shaft 1. The outer rotor 3 and the inner rotor 7 are respectively provided with copper rings or magnets, that is, when the outer rotor 3 is a copper ring, the inner rotor 7 is a magnet; when the outer rotor 3 is a magnet, the inner rotor 7 is a copper ring. There is an air gap between the copper ring and the magnet.

[0039] In this embodiment, the structure between the inner rotor 7 and the driven shaft 1 is optimized, and the specific settings are as follows:

[0040] The pin ring 8 is fixed on the inner rotor 7 , and one end of the driven flange 9 is connected to the driven shaft 1 , and the other end is arranged at the position of the pin ring 8 . An arc-shaped safety pin 10 is arranged between ...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the arc-shaped safety pin 10 in this embodiment is made of nylon material.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 or 2 is that in order to achieve the purpose of fixing the air gap between the copper ring and the magnet, the structure between the outer rotor 3 and the inner rotor 7 is optimized in this embodiment, such as figure 1 and figure 2 As shown, the specific settings are as follows:

[0047] The motor connecting shaft 12 is provided with an extension section extending to the position of the driven shaft 1. The extension section is located between the outer rotor 3 and the inner rotor 7. The inner rotor 7 is provided with a parallel section parallel to the extension section. The section and the extension section are connected by angular contact ball bearings 6 .

[0048]Through the setting of the above structure, the air gap between the copper rings on the outer rotor 3 and the inner rotor 7 and the magnets can be effectively ensured.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap