Shaftless screw gear power generation device

A power generation device, shaftless technology, applied in the direction of electromechanical devices, ocean energy power generation, electrical components, etc., can solve problems such as damage to blades and loss of motive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] Below in conjunction with accompanying drawing, implement the further description of the product of the present invention.

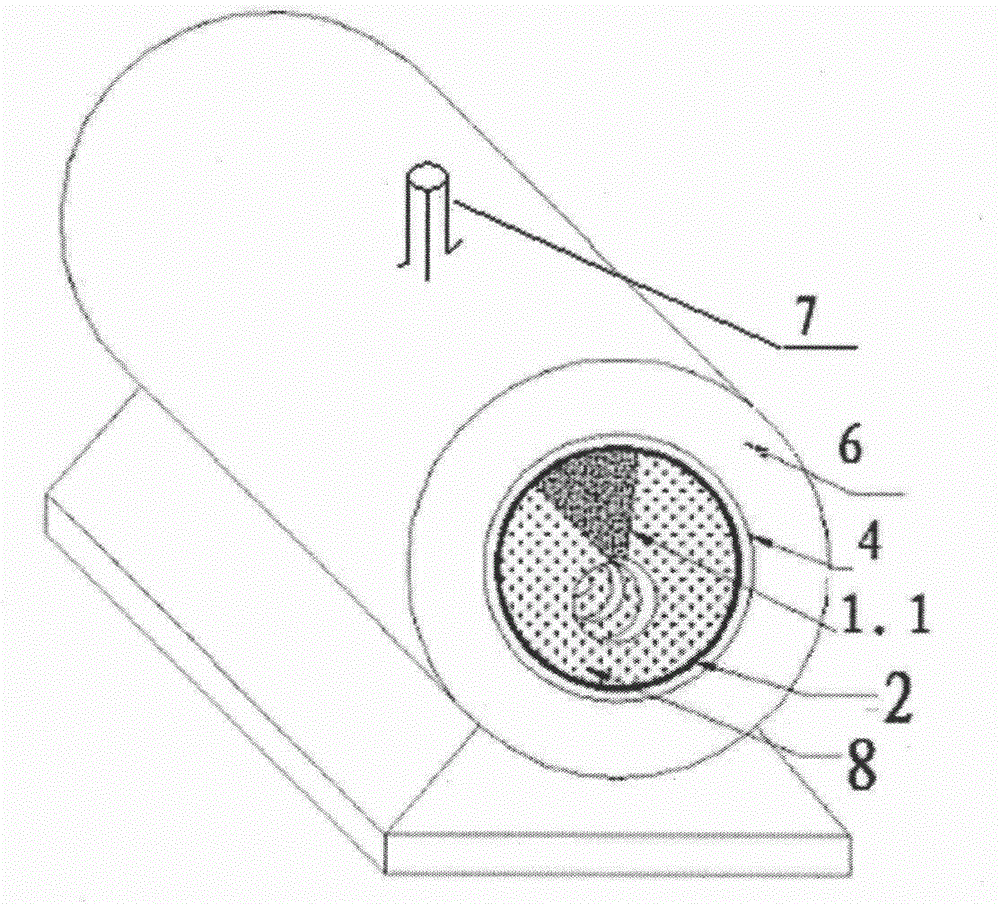

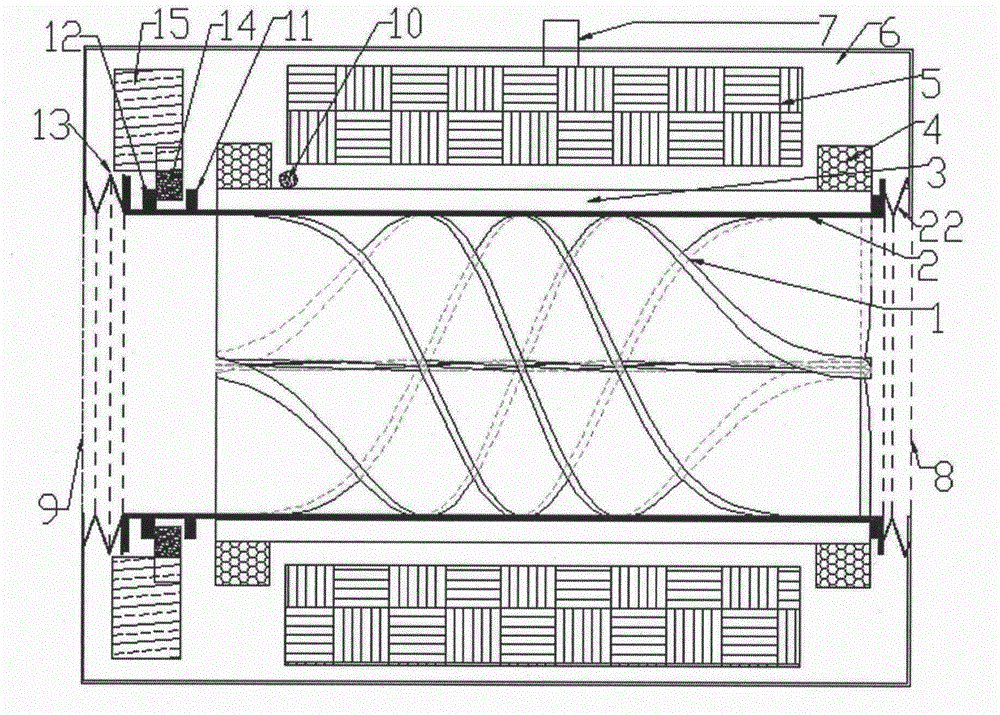

[0131] According to attached Figure 10 The principle block diagram of the product, the present invention relates to the normal condition of the product, the motive force enters from the input port (8), drives the helical wheel (1) to rotate radially, because the helical wheel is fixedly embedded in the inner wall of the rotor (2), it rotates synchronously. The outer wall of the rotor (3) has its own magnetic force or induced magnetic force. According to the right-hand rule, through the induction method, the coil of the induction unit (5) fixed in the housing can instantly obtain an induced current through the induction method. The output of the multifunctional interface (7) of the body (6) can be transmitted to the power grid after being rectified and stored and accumulated, and the motive force that cannot be reused is discharged from the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com