Drive system of linear motor and drive method of linear motor

A technology of linear motors and driving methods, applied in control systems, electric components, AC motor control, etc., can solve the problems of increasing output force by electromagnetic force and inappropriate positive and negative directions of electrical signals, etc., and achieve the effect of large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

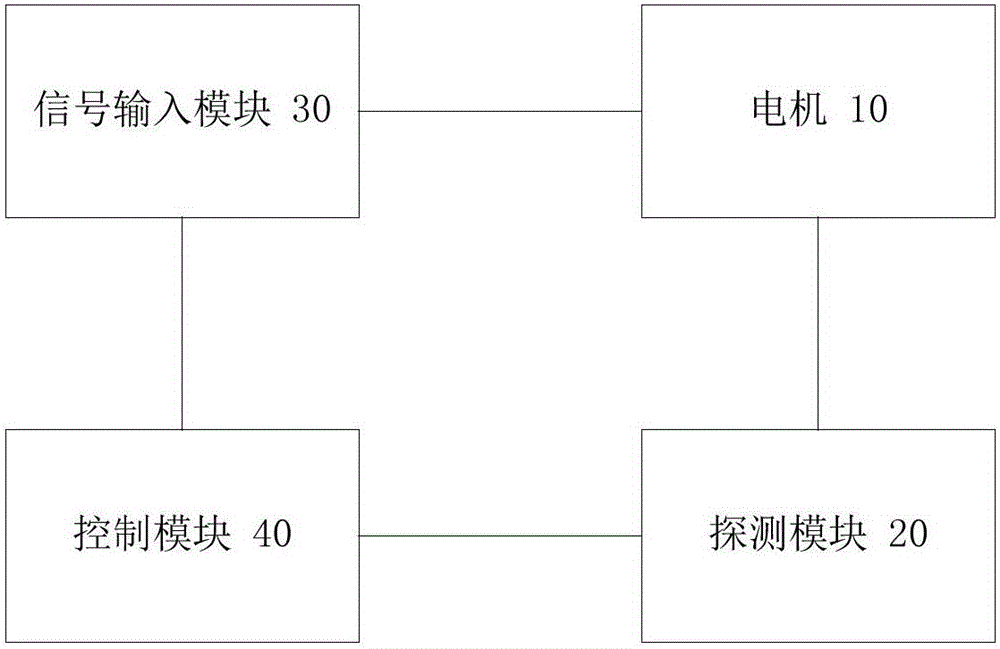

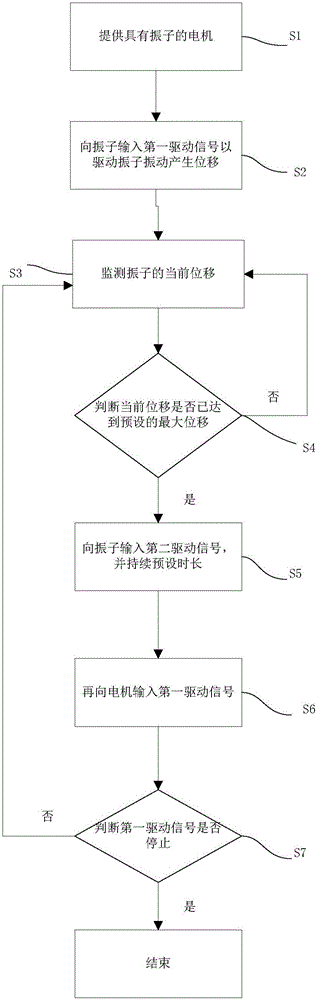

[0019] see figure 1 , a linear motor drive system provided by the present invention includes a motor 10 with a vibrator, a detection module 20 for monitoring the current displacement of the vibrator, a signal input module 30 and a control module 40 .

[0020] The signal input module 30 is used for inputting the first driving signal for driving the vibrator to vibrate to generate displacement and the second driving signal for providing the vibrator with an electromagnetic force opposite to its current displacement direction.

[0021] The control module 40 controls the signal input module 30 to input the first drive signal to the motor 10, receives the current displacement of the vibrator sent by the detection module 20 and judges whether the current displacement is greater than or equal to the preset maximum displacement of the vibrator. When the curren...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap