Sound box handle mechanism and assembly method thereof

A technology of audio and mounting holes, which is applied in the field of audio handle mechanism and its assembly, can solve the problems of high production cost, fracture, and insufficient connection strength, and achieve the effect of improving assembly efficiency, improving bearing capacity, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

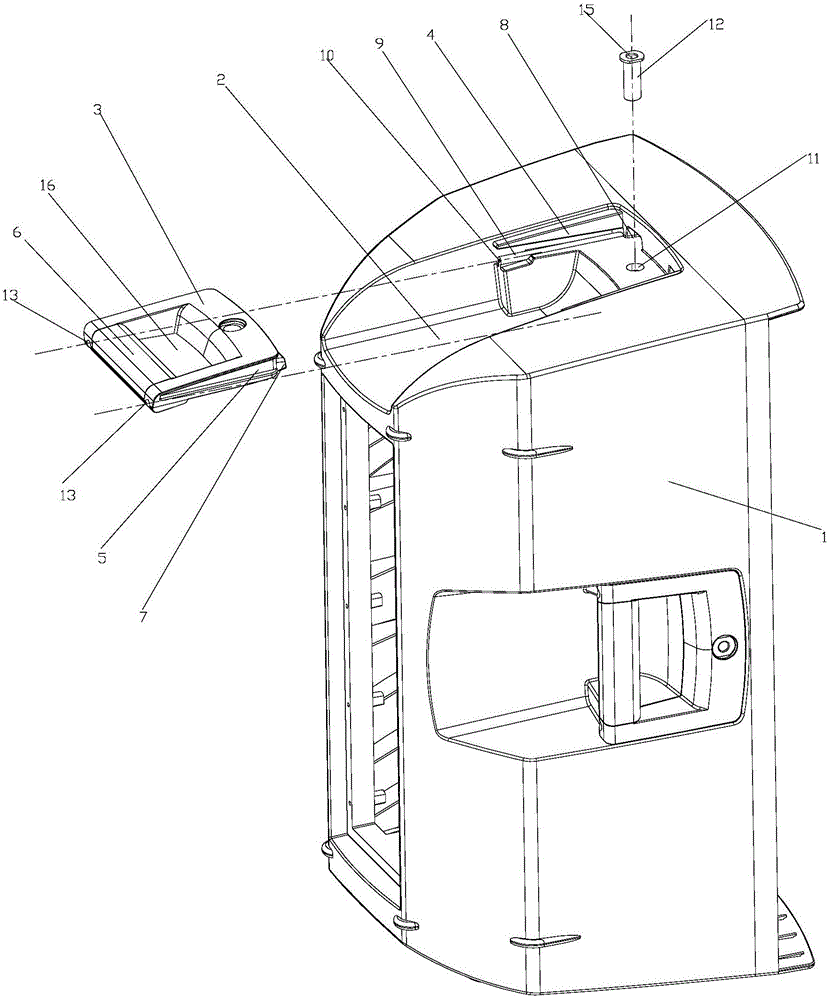

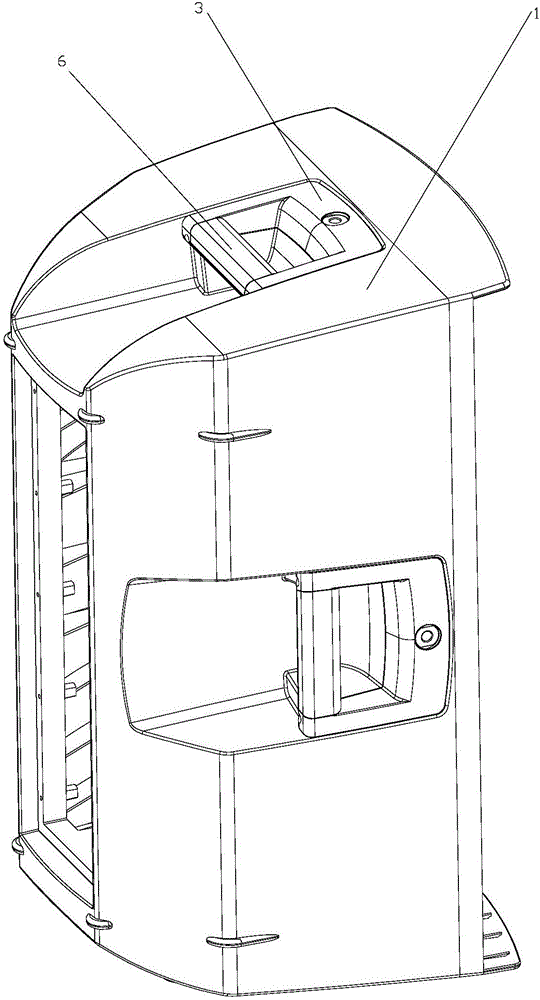

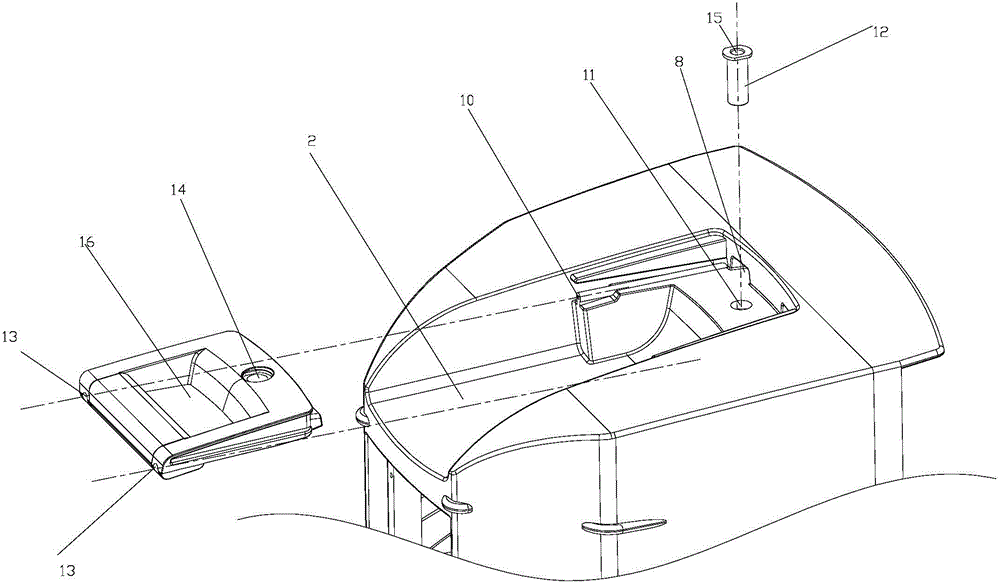

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] The audio handle mechanism and its assembly method of the present invention include an audio body 1, an opening groove 2 is arranged on the audio body 1, a slide plate 3 is slidably connected to the opening groove 2, and elongated oblique blocks 4 are arranged on both sides of the opening groove 2, Both sides of the slide plate 3 are provided with chute 5 matching the shape of the inclined block 4; the slide plate 3 is provided with a hollow structure 16 for fingers to pass through, and the side of the hollow structure 16 close to the opening of the opening groove 2 is provided with a cross bar for holding 6. On the side of the slide plate 3 away from the cross bar 6, there is an insert 7, and the opening slot 2 is provided with a blind hole 8 for inserting the insert 7, and the shape of the blind hole 8 matches the shape of the insert 7;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap