fuel pumping mechanism

A technology of pumping mechanism and fuel pump, applied in the direction of fuel injection pump, fuel injection device, pump, etc., can solve problems such as edge contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

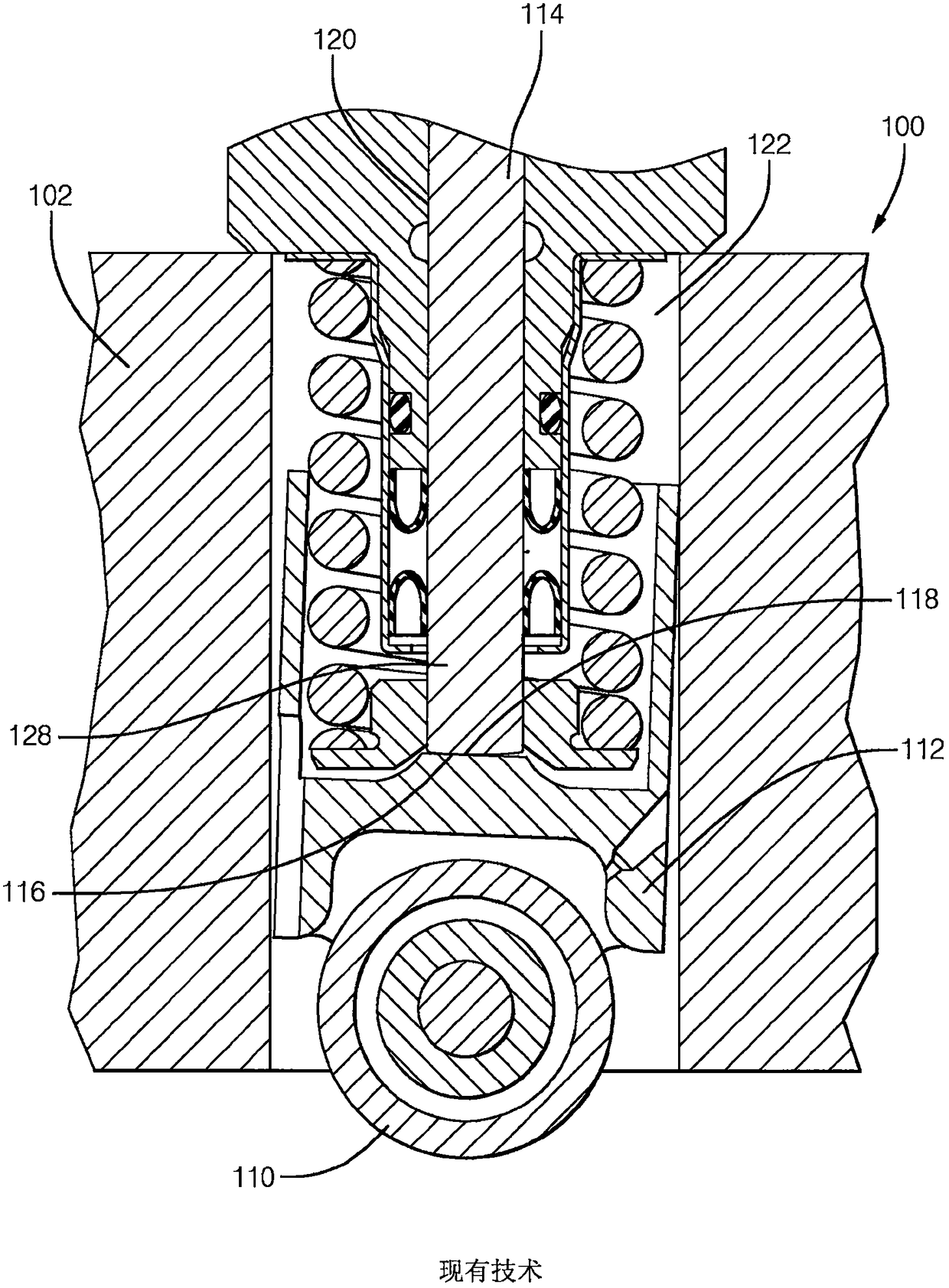

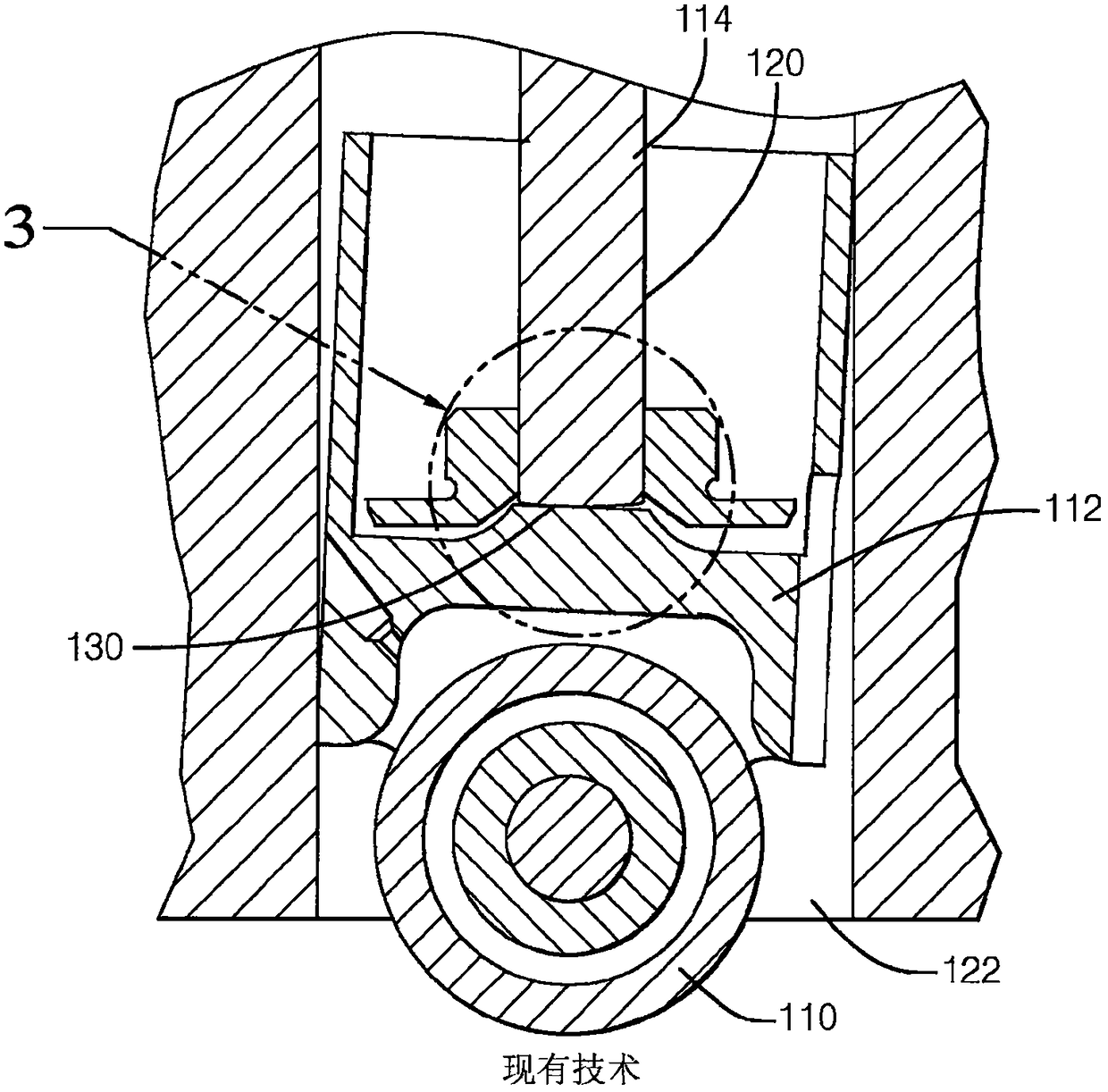

[0018] refer to Figure 4 , the present invention includes a pumping mechanism 200 that includes a pump housing 202 . Pump housing 202 includes a plunger positioning bore 220 for positioning a pumping element in the form of plunger 214 , a drive mechanism including cam roller 210 , and an intermediate member including lifter 212 positioned in lifter positioning bore 222 .

[0019] The plunger locating bore 220 defines at one end a pumping chamber 224 into which a first end 226 of the plunger 214 extends.

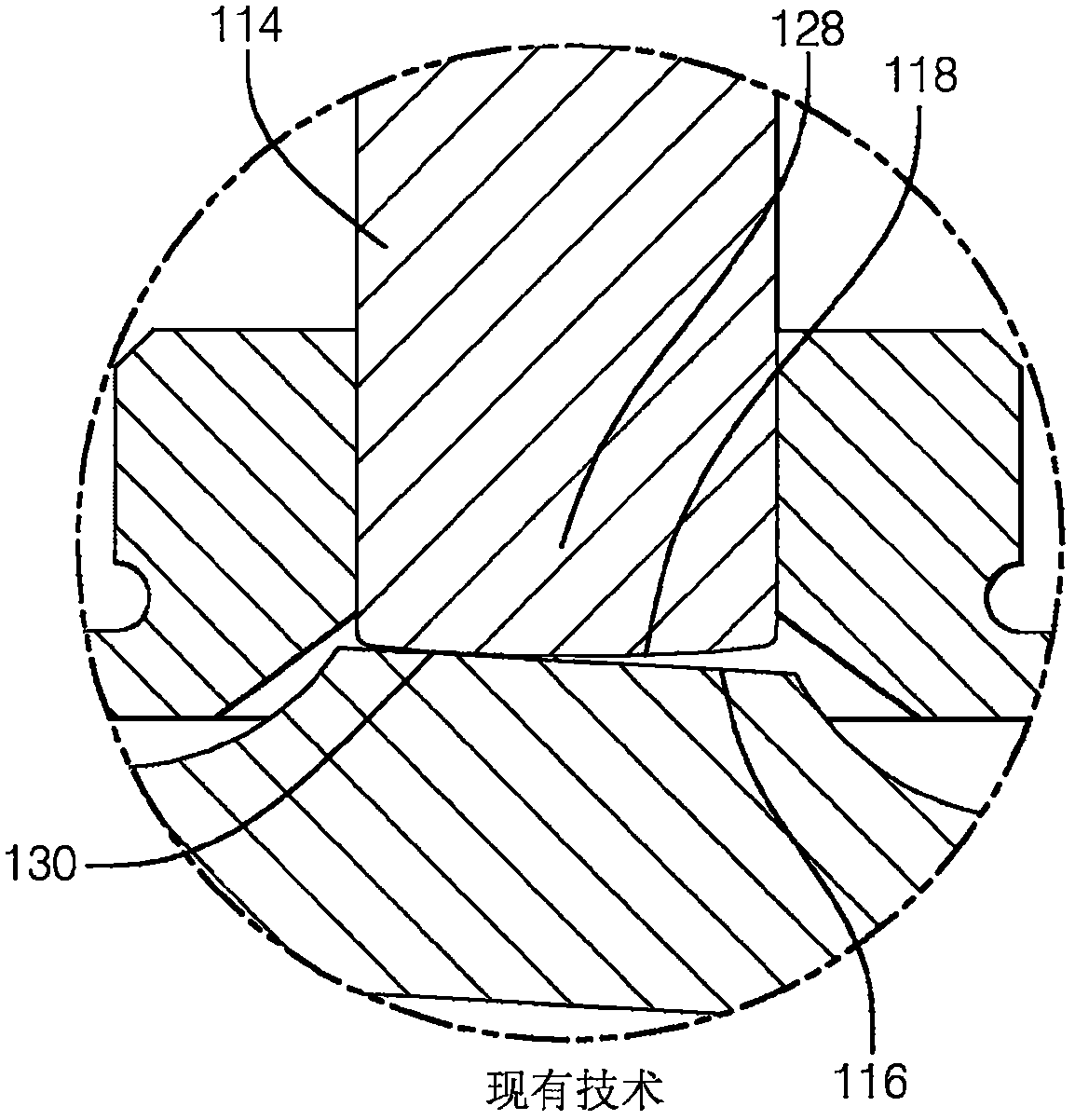

[0020] Such as Figure 6 and Figure 8 As shown, the tappet 212 is provided with a plunger contact surface 218 ( Figure 6 ) contacting tappet contact surface 216. The figure represents a pumping stroke where the tappet contact surface 216 is in contact with the plunger contact surface 218 ie the load from the cam roller 210 is transferred via the contact surface 216 of the tappet 212 to the contact surface 218 of the plunger 214 . Accordingly, the plunger 214 is pushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com