Capacitive level sensor circuit

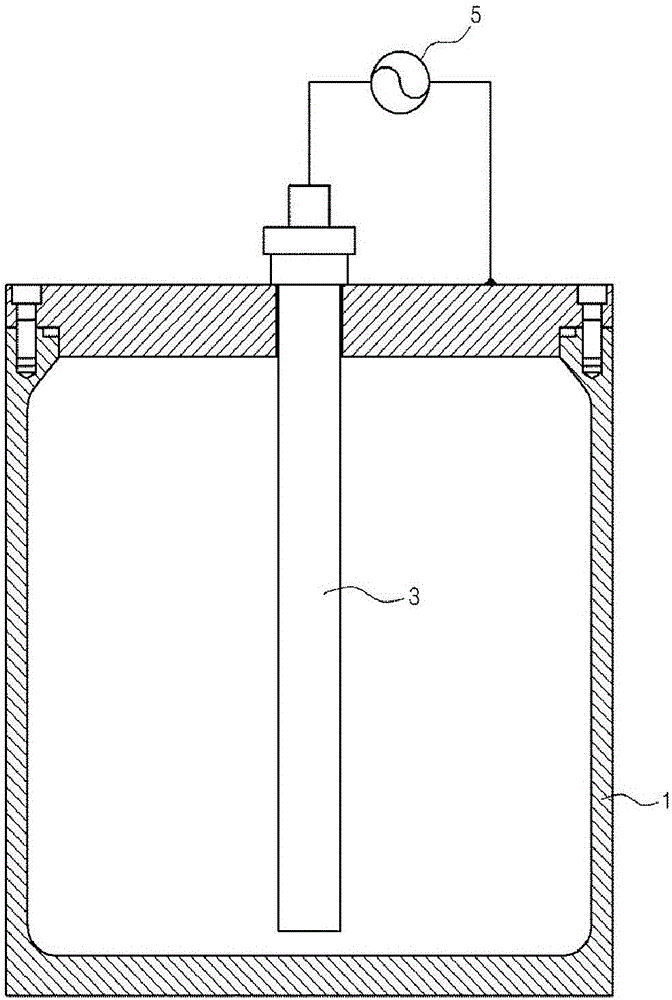

A water level detection circuit, capacitive technology, applied in measurement devices, liquid/fluid solids measurement, liquid level indicators for physical variable measurement, etc., can solve problems such as reduced reliability and durability, incorrect operation, and shortened component life. , to achieve the effect of preventing detection action and chattering, stable circuit operation and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

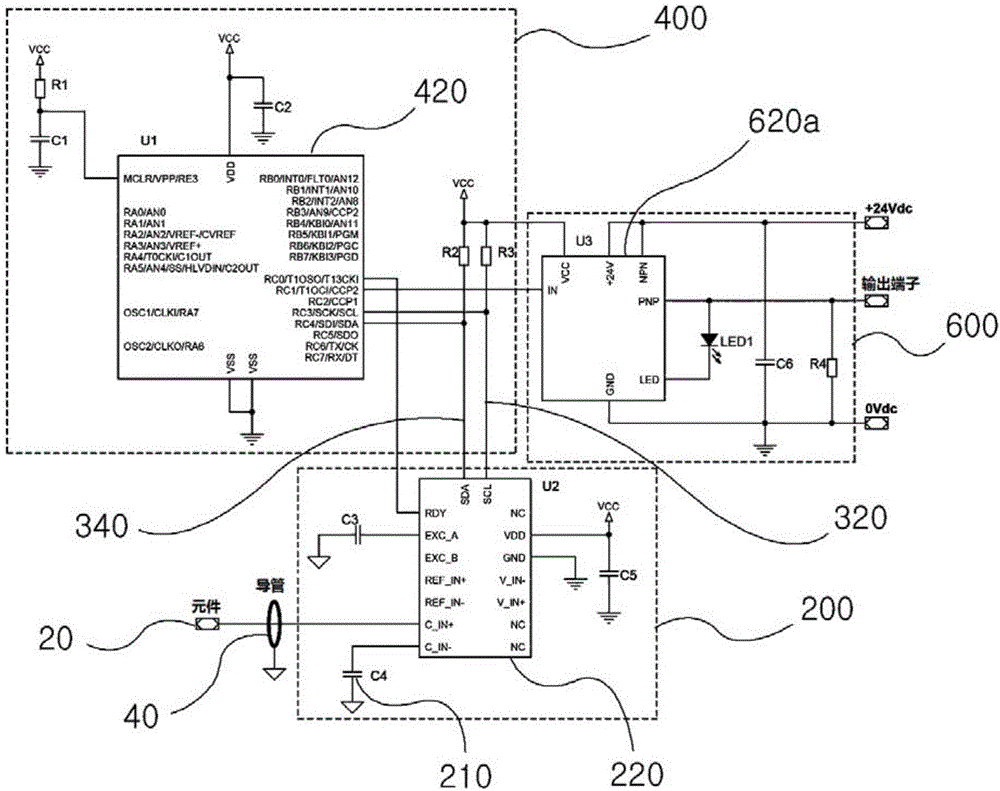

[0035] figure 2 It is a circuit diagram showing the capacitive water level detection circuit of the first embodiment of the present invention.

[0036] If the sensor rod 20 and the conduit 40 are located outside the liquid level, the first control unit 220 transmits the low signal to the second control unit 420 through the SCL and SDA ports as synchronous serial communication ports, and the second control unit 420 transmits the low signal through the output port. The signal is transmitted to the third control unit 620a, and the third control unit 620a outputs a low signal through the PNP output port and transmits it to the external output terminal (OUTPUT).

[0037]Therefore, according to the capacitance of the liquid level sensor rod 20 and the conduit 40 changes, the first control unit 220 compares the capacitance with the capacitor 210, and when the capacitance measured by the sensor rod 20 and the conduit 40 is smaller than the capacitance of the capacitor 210 , the firs...

no. 2 example

[0041] image 3 It is a circuit diagram showing the capacitive water level detection circuit of the second embodiment of the present invention.

[0042] In the second embodiment, because the output port of the third control unit 620b is of NPN type, only the output signal is opposite to that of the first embodiment described above, and the rest of the structure is the same or very similar, so it will not be repeated here.

no. 3 example

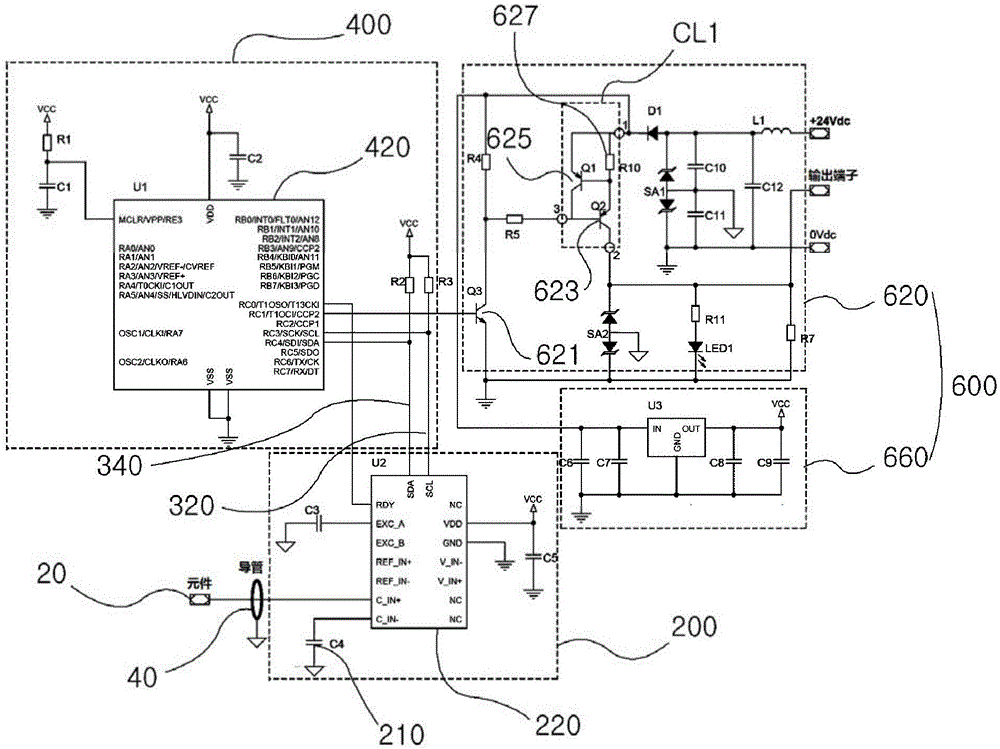

[0044] Figure 4 It is a circuit diagram showing the capacitive water level detection circuit of the third embodiment of the present invention.

[0045] If the sensor rod 20 and the conduit 40 are located outside the liquid level, the first control unit 220 transmits a low signal to the second control unit 420 through the SCL and SDA ports as synchronous serial communication ports, and the low signal of the second control unit 420 is output to The base terminal of the first transistor 621 of NPN type, and the collector terminal of the above-mentioned first transistor 621 is applied with the base terminal of the second transistor 623 of PNP type in a high state, and the above-mentioned second transistor The emitter terminal of the 623 outputs a low signal.

[0046] According to the change of the capacitance of the water level sensor rod 20 and the conduit 40 of the liquid, the first control unit 220 compares the capacitance of the capacitor 210, and when the capacitance measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com