A knife advance and retreat mechanism for end surface bevel processing equipment

A technology of bevel processing, advancing and retreating knives, applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problem that the bevel gear assembly is easy to be damaged, the guide block is difficult to process and manufacture, and the universal coupling cannot be rigid. Transmission and other issues, to achieve the effect of maintaining axial stability and improving the efficiency of groove processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

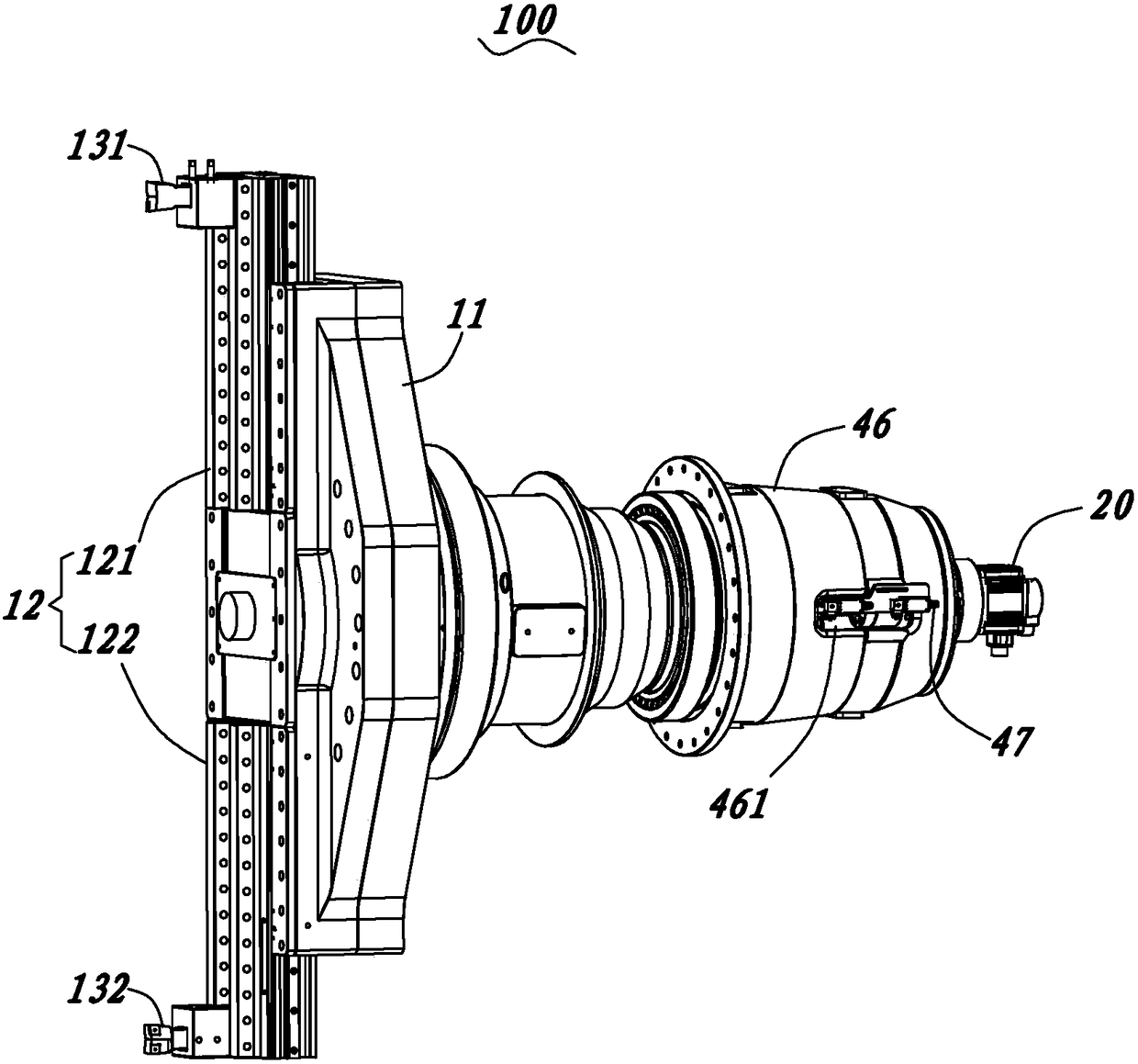

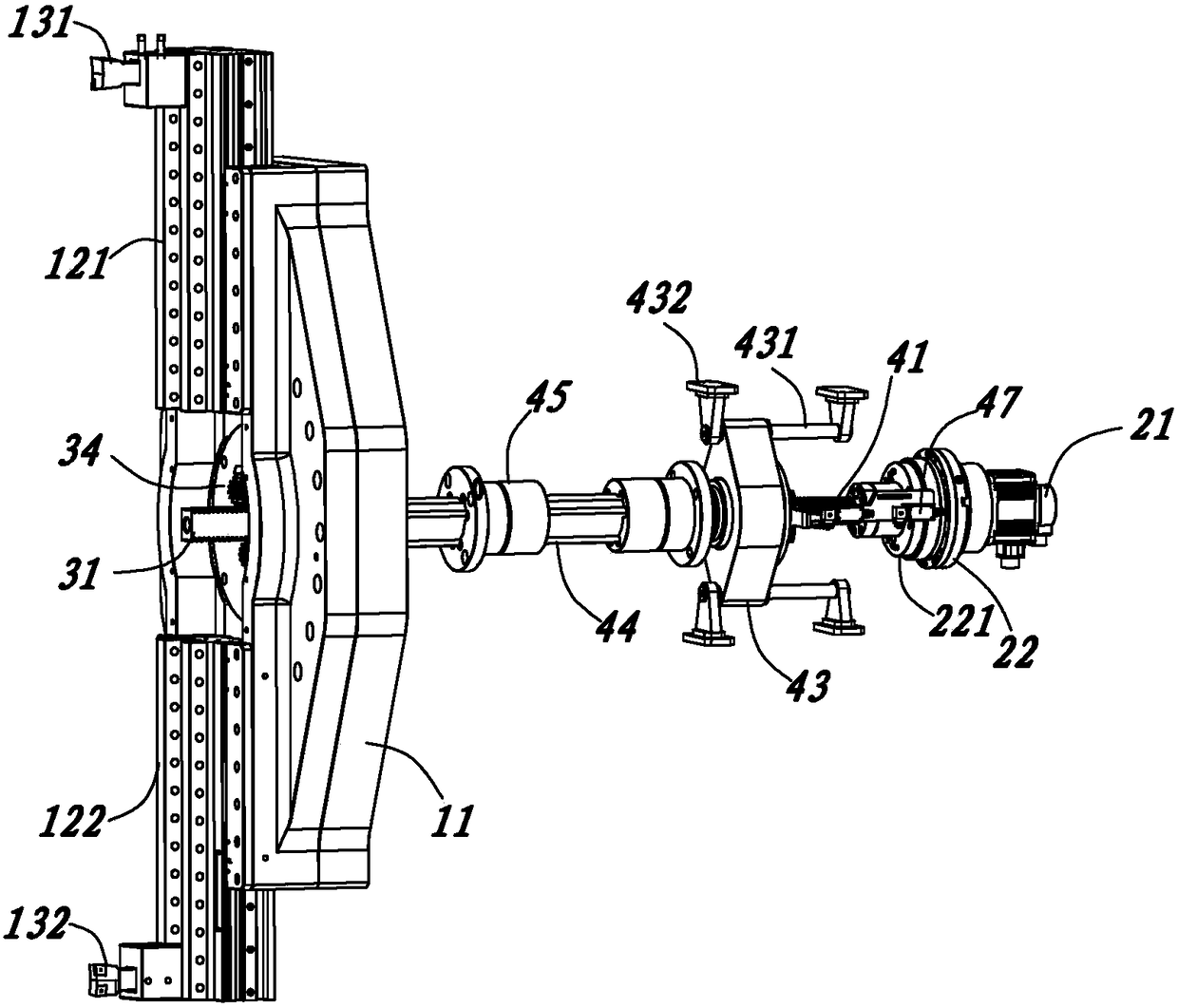

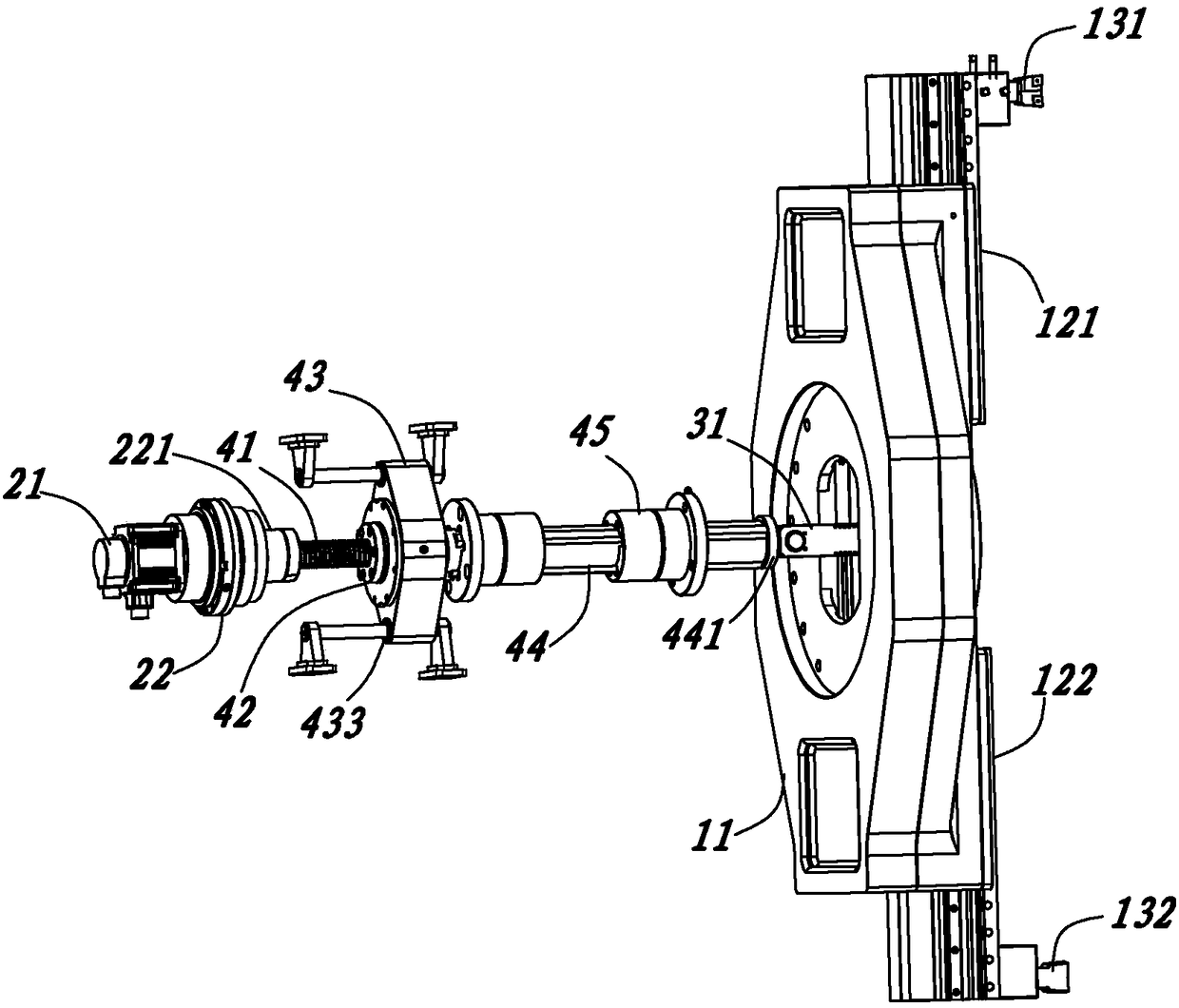

[0028] see Figure 1 to Figure 11 Shown is a preferred embodiment of the present invention. Such as figure 1 As shown, the advancing and retracting mechanism 100 includes a cutterhead 11 , a cutter seat 12 mounted on the front side of the cutter head 11 , and a driving assembly 20 for driving the cutter seat 12 to move radially of the cutter head 11 . Wherein, the knife seat 12 includes a first knife seat 121 and a second knife seat 122 arranged symmetrically along the center of the cutter head 11, and the first knife seat 121 and the second knife seat 122 are respectively used for installation and slope The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com