A double-opening braided mesh soft joint artificial muscle

A technology of artificial muscles and weaving nets, which is applied in the field of artificial muscles, can solve problems affecting the service life of artificial muscles, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and embodiments.

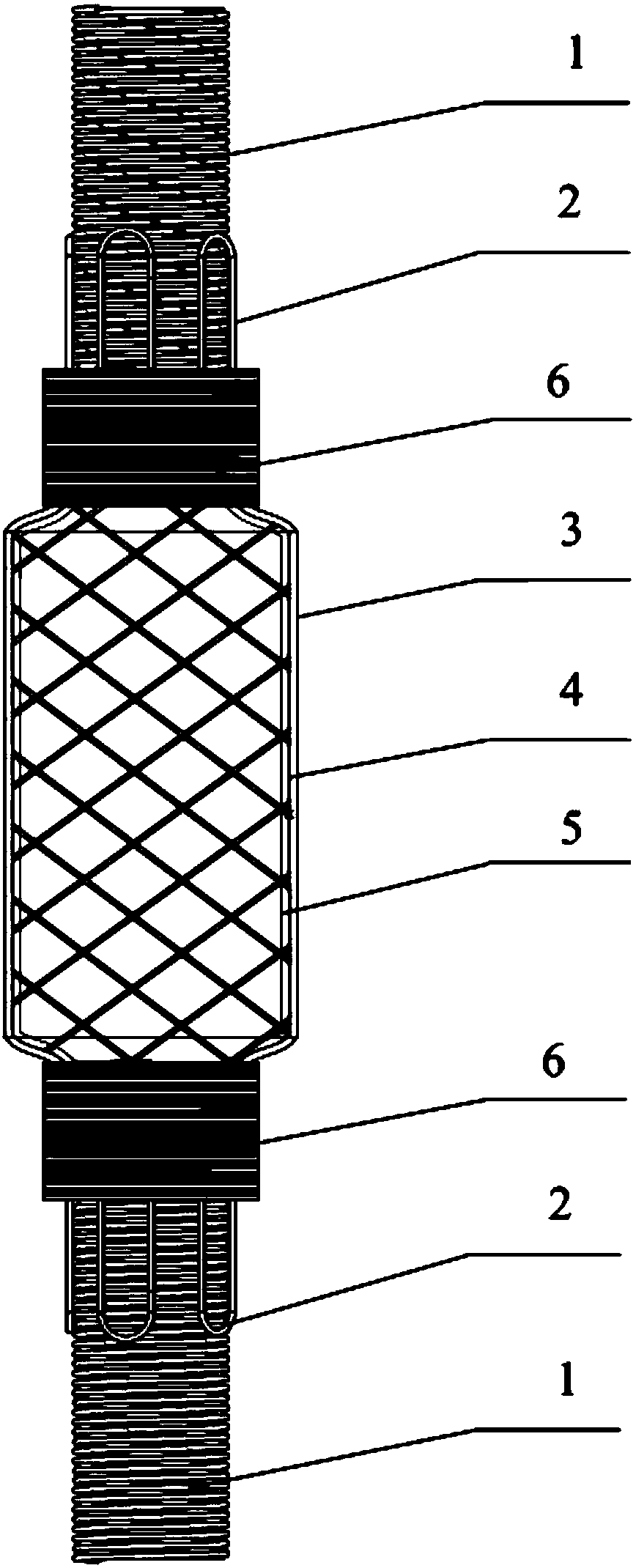

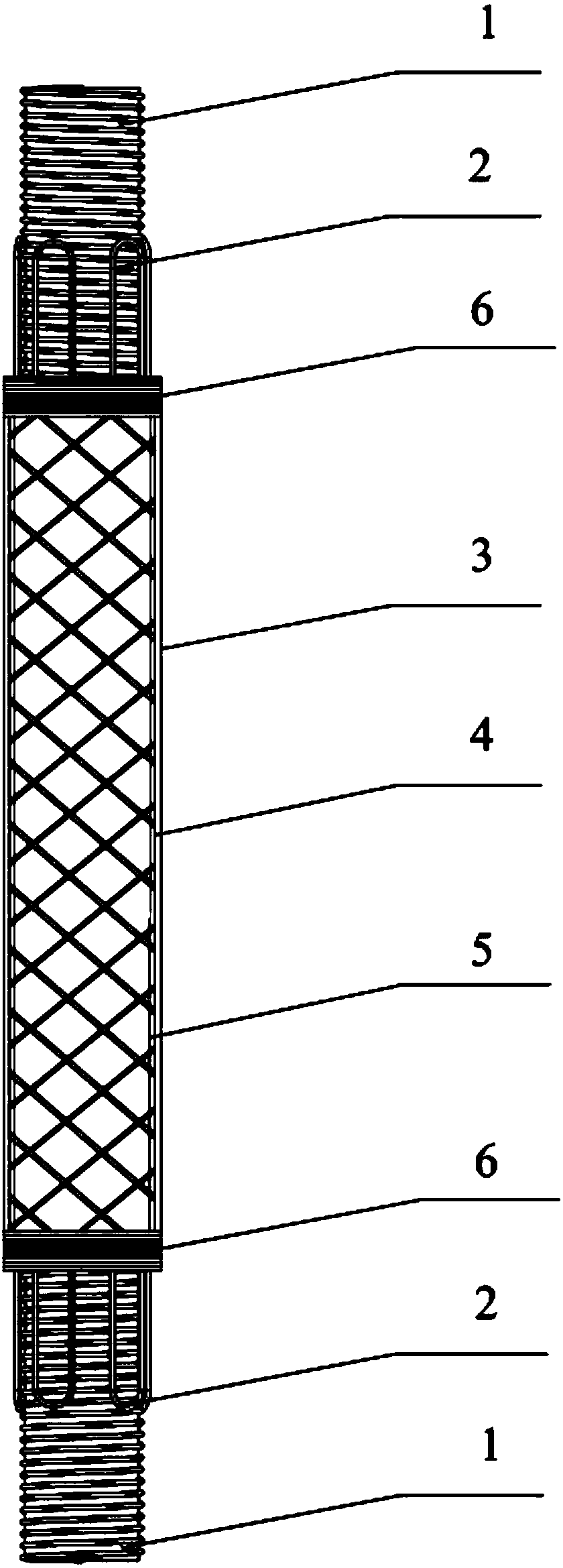

[0025] As shown in Figure 1, a double-opening woven mesh type soft joint artificial muscle includes an inner rubber tube 5, a woven mesh 4 arranged on the outer side of the inner rubber tube 5 along the axial direction, and located at both ends of the inner rubber tube 5 and connected with The end fixing line 2 of the woven net 4 is integrated. The woven net 4 wraps the part of the inner rubber tube 5 between the two ends. The part of the inner rubber tube 5 that is not wrapped by the woven net 4 is used with an external pressure tight line 1 is tightly wound to form a pressure-bearing catheter, and the inner layer of rubber tube 5 is wound with a sealing end compression line 6 outside the adjacent end fixing line 2. The woven net 4 is made of hard material. The woven net 4 is made of a soft material, and an outer rubber tube 3 is arranged outside the inner rubber tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com