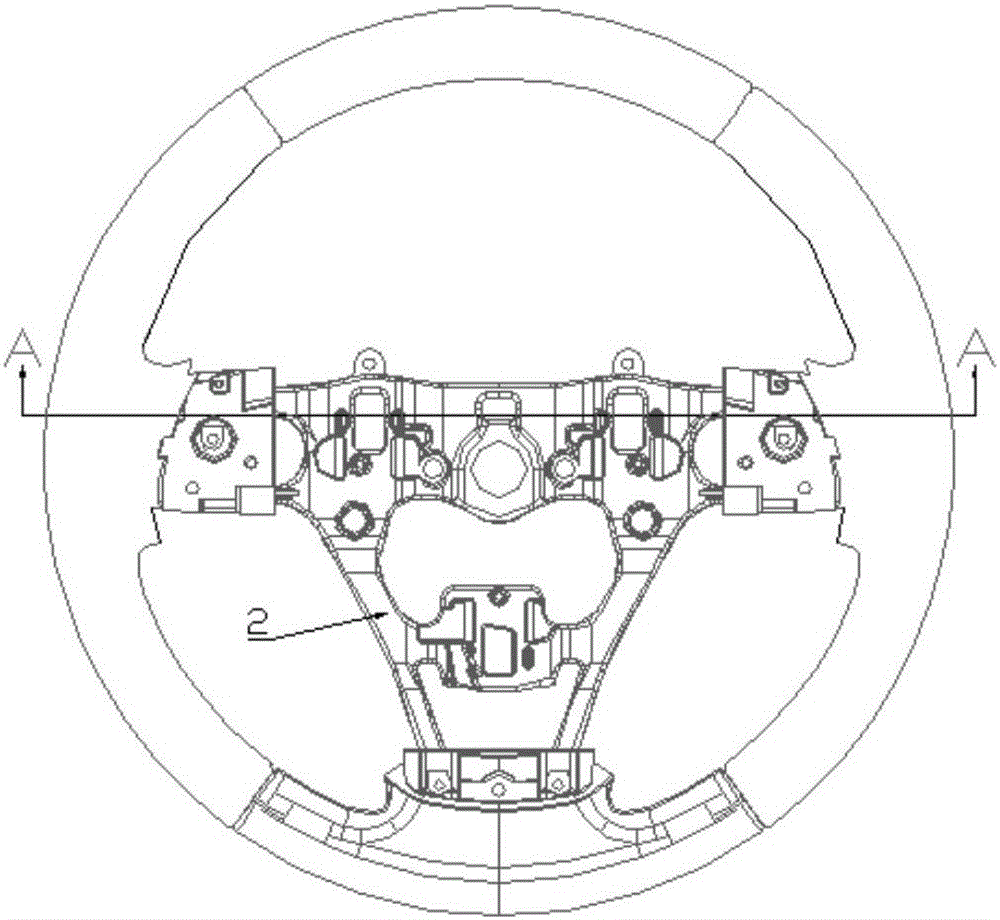

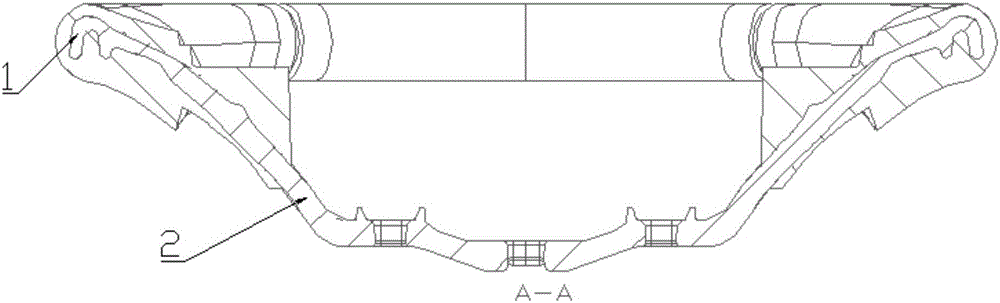

Automobile steering wheel with dual-density EPP (Expanded Polypropylene) structure and manufacturing process thereof

A manufacturing process and steering wheel technology, which is applied to the steering control installed on the car, household appliances, and other household appliances. It can solve the problems of unenvironmental protection of the processing technology, difficult size control, and hard hand feeling of the steering wheel, so as to reduce the size control and The difficulty of product processing, the effect of improving comfort and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

[0037] A kind of automobile steering wheel manufacturing process with double-density EPP structure, comprises the following steps:

[0038] Step 1. Cast the metal skeleton of the steering wheel by casting;

[0039] Step 2, manufacturing the EPP material forming mold, the forming mold has a mold partition, and the partition divides a cavity into different regions;

[0040] Step 3, spraying low-temperature PP resin on the metal surface of the outer ring of the steering wheel metal skeleton obtained in step 1;

[0041] Step 4, the product obtained in step 3 is placed in the EPP material forming mold, and the EPP material in different EPP material tanks is injected into different regions in the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com