A new type of sealing machine

A sealing machine, a new type of technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve problems such as low replacement efficiency, damage to conveyor belts, affecting transmission structure coordination, etc., to achieve easy disassembly and installation, and structural flexibility. High, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

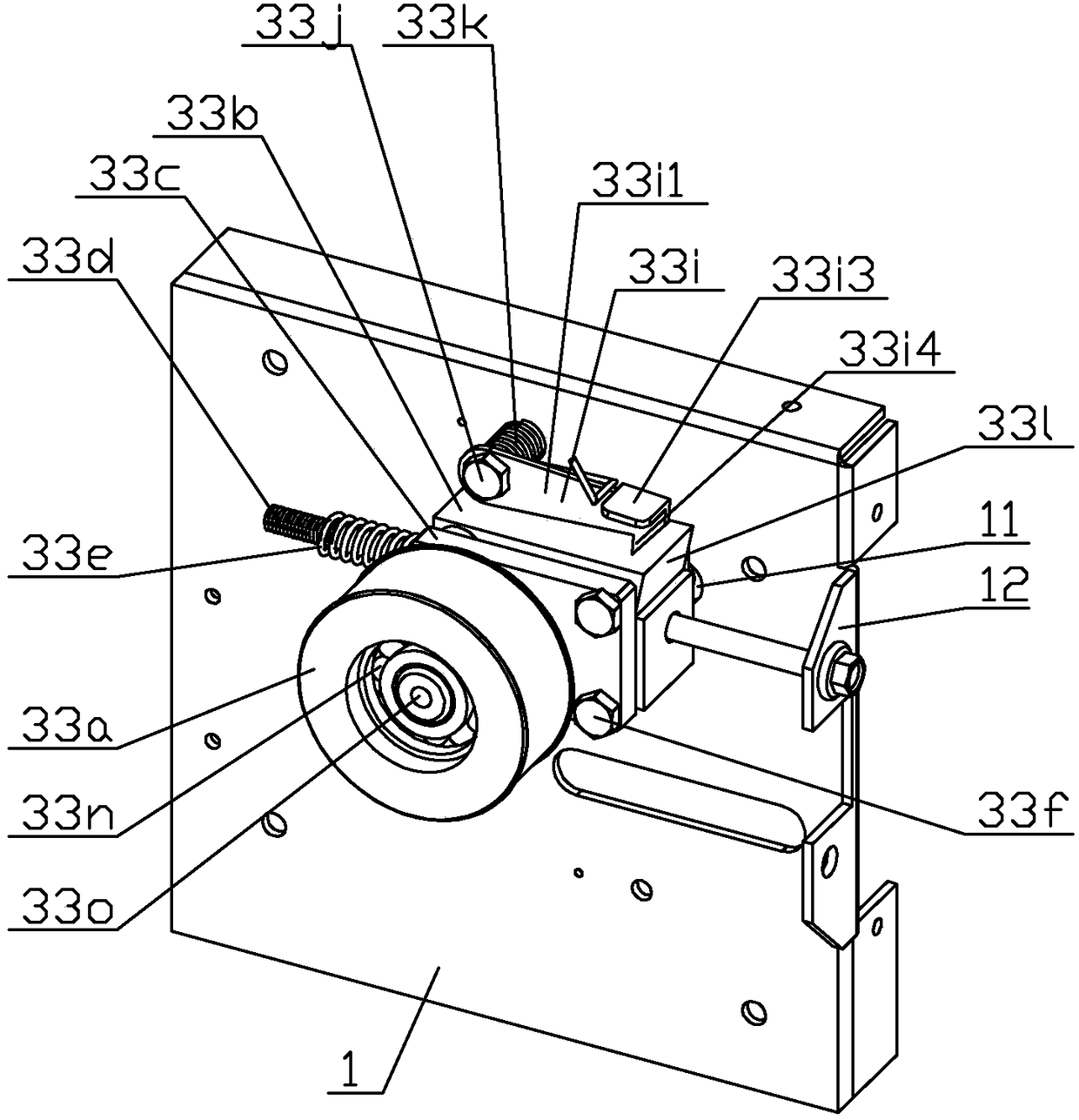

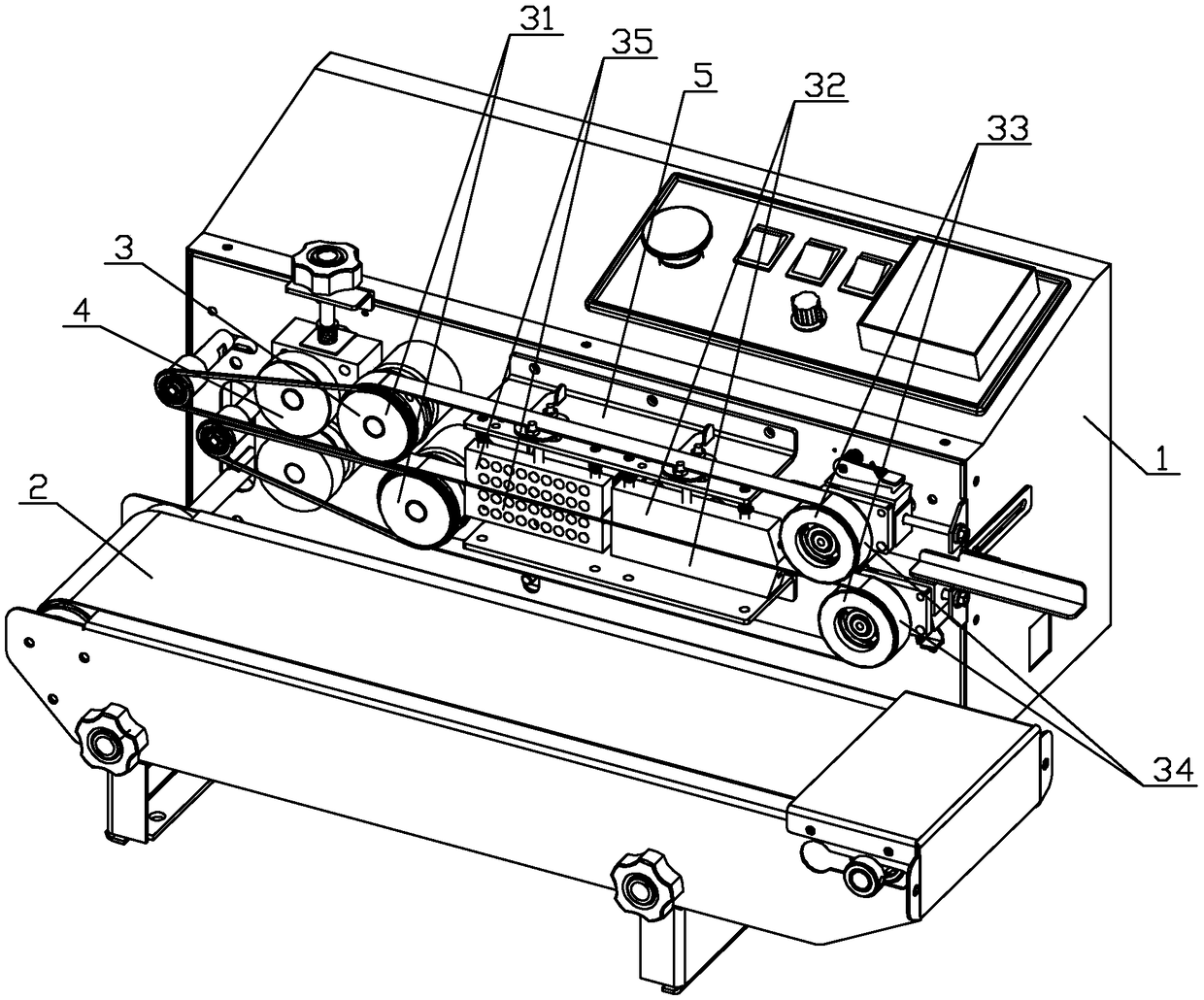

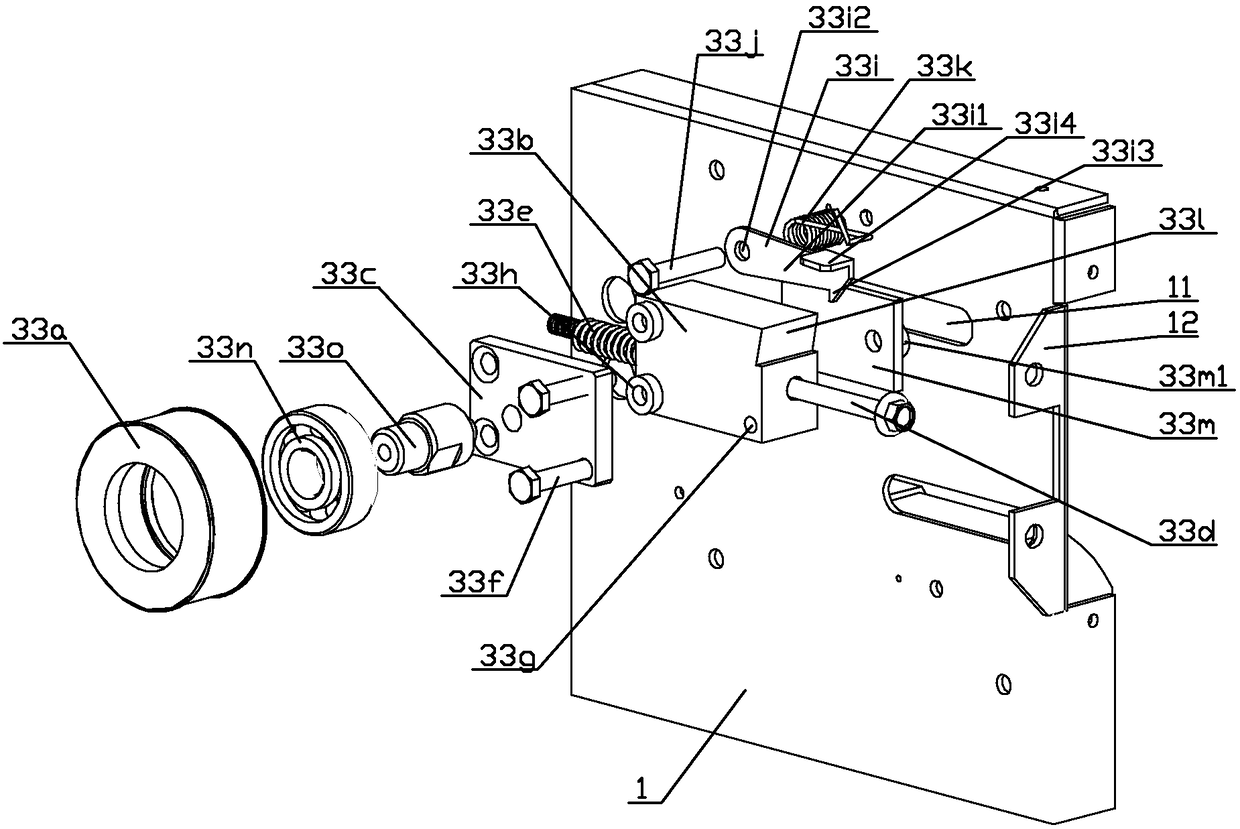

[0024] Such as Figure 1-8Shown is a specific embodiment of the sealing machine of the present invention. This embodiment 1, a new type of sealing machine, including a body 1, a conveying mechanism 2, a sealing mechanism 3 and an embossing mechanism 4, the sealing mechanism 3 and the embossing mechanism 4 are sequentially arranged on the body 1, and the conveying mechanism 2 is located at the bottom of the body 1 The side is arranged in parallel with the sealing mechanism 3 and the embossing mechanism 4. It is characterized in that: the sealing mechanism 3 includes a drive wheel mechanism 31, a heating mechanism 32, a cooling mechanism 35 and a driven wheel mechanism 33 that are symmetrically arranged up and down in groups. The sealing conveyor belt 34 is set on the wheel mechanism 31 and the driven wheel mechanism 33, and the heating mechanism 32 and the cooling mechanism 35 are located between the driving wheel mechanism 31 and the driven wheel mechanism 33 and are wrapped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com