Composite well lid with double sealing belts and drainage portions

A technology of drainage and double sealing, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of micro-leakage of sealing belts, long-term immersion corrosion of sealing belts, long-term immersion and corrosion, etc., to prevent micro-seepage Leakage, good ventilation, keeping clean and tidy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

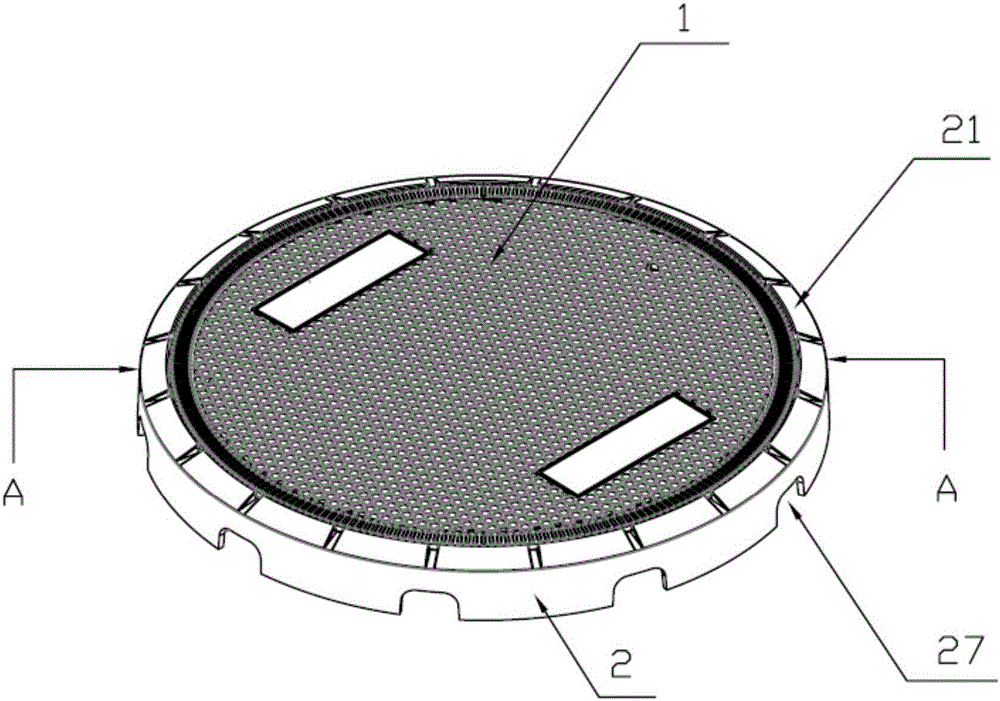

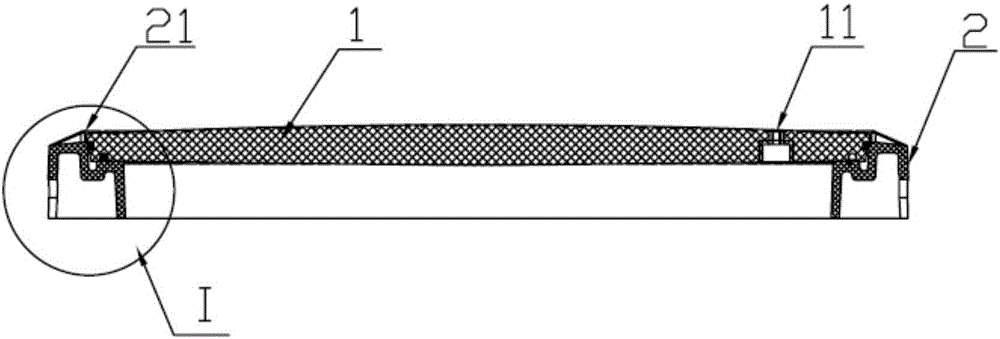

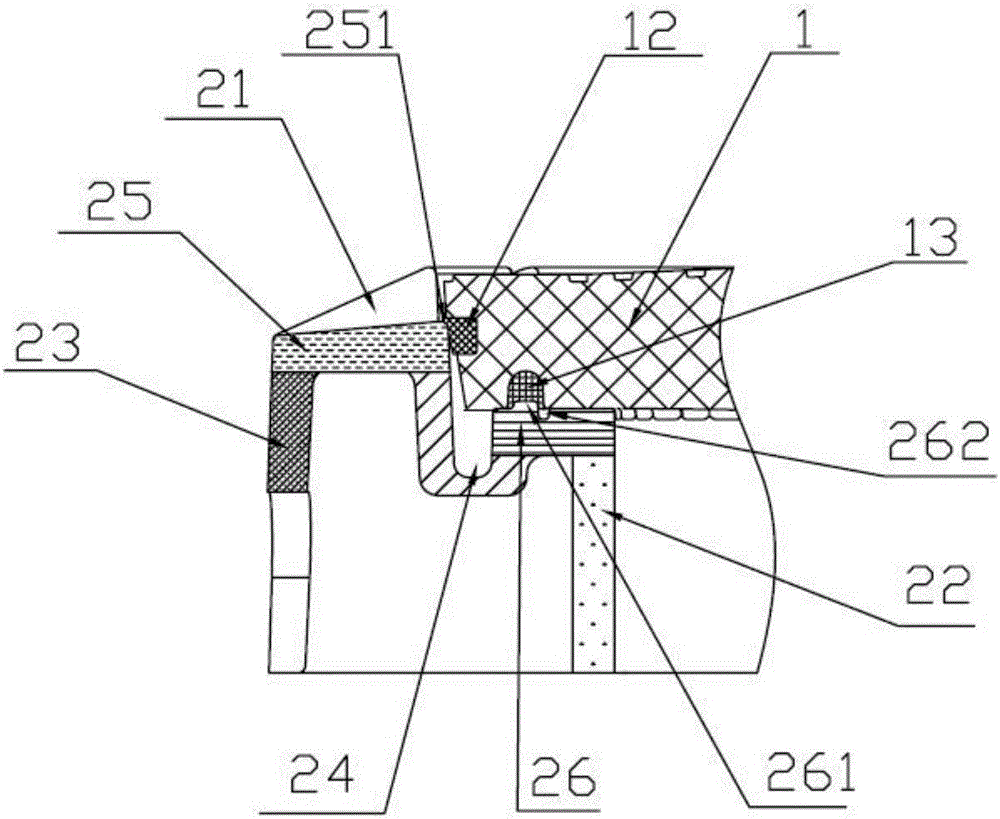

[0024] A composite manhole cover with double sealing strips and drainage parts. The composite manhole cover includes a well base 2 and a well cover 1 located on the upper part of the well base. The well cover 1 is provided with an opening 11. The well base 2 includes an outer wall 23, an inner wall 22, and an outer wall 23 and an inner wall. In the groove 24 between 22, the height of the inner wall 22 is lower than that of the outer wall 23. When the well cover is placed, the well base 2 and the well cover 1 are on the same level, and the lower part of the outer wall 23 is evenly distributed with vents 27. The top of the outer wall 23 passes through the first A connection plate 25 is fixedly connected to the top of the first side wall of the groove 24. The upper surface of the first connection plate 25 forms an angle of 10° with the horizontal plane. The longitudinal section of the first connection plate 25 is trapezoidal. The first connection The upper surface of the board 25 ...

Embodiment 2

[0026] A composite manhole cover with double sealing strips and drainage parts. The composite manhole cover includes a well base 2 and a well cover 1 located on the upper part of the well base. The well cover 1 is provided with an opening 11. The well base 2 includes an outer wall 23, an inner wall 22, and an outer wall 23 and an inner wall. In the groove 24 between 22, the height of the inner wall 22 is lower than that of the outer wall 23. When the well cover is placed, the well base 2 and the well cover 1 are on the same level, and the lower part of the outer wall 23 is evenly distributed with vents 27. The top of the outer wall 23 passes through the first A connection plate 25 is fixedly connected to the top of the first side wall of the groove 24, the upper surface of the first connection plate 25 forms an angle of 30° with the horizontal plane, the longitudinal section of the first connection plate 25 is trapezoidal, and the first connection The upper surface of the plate...

Embodiment 3

[0028]A composite manhole cover with double sealing strips and drainage parts. The composite manhole cover includes a well base 2 and a well cover 1 located on the upper part of the well base. The well cover 1 is provided with an opening 11. The well base 2 includes an outer wall 23, an inner wall 22, and an outer wall 23 and an inner wall. In the groove 24 between 22, the height of the inner wall 22 is lower than that of the outer wall 23. When the well cover is placed, the well base 2 and the well cover 1 are on the same level, and the lower part of the outer wall 23 is evenly distributed with vents 27. The top of the outer wall 23 passes through the first A connection plate 25 is fixedly connected to the top of the first side wall of the groove 24, the upper surface of the first connection plate 25 forms an angle of 20° with the horizontal plane, the longitudinal section of the first connection plate 25 is trapezoidal, and the first connection The upper surface of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com