A composite door and window profile made of plastic and reinforced inner lining

A door and window profile and lining technology, applied in windows/doors, building components, buildings, etc., can solve problems such as unstable processing technology, difficult product quality control, unstable molding, etc., achieve good promotion and application value, and stable processing technology , The effect of product quality controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

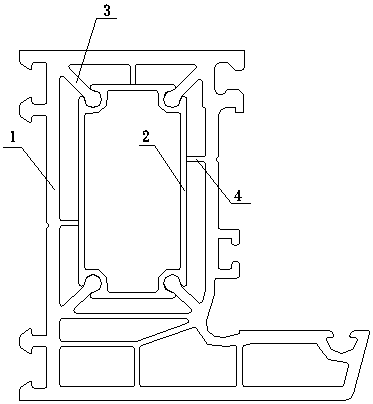

[0033] A door and window profile composited with plastic and reinforced lining, comprising an outer plastic layer 1 and a reinforced inner lining 2, the outer plastic layer 1 and the reinforced inner lining 2 are connected by a connecting bridge 3 .

[0034] Several supporting bridges 4 are arranged between the outer plastic layer 1 and the reinforced inner lining 2 .

[0035] A number of cavities are set up between the outer plastic layer 1 and the reinforced inner lining 2, and thermal insulation materials are injected into the cavities.

[0036] like Figure 13 , 14 As shown, the reinforced inner lining 2 is provided with several cavities 6, and the cavities 6 are filled with thermal insulation materials.

[0037] like Figure 8 , 9 As shown in , 15, there are several reinforcing inner linings 2, and connecting bridges 3 are connected between the reinforcing inner linings 2, and the connecting bridges can reduce heat transfer.

[0038] The connecting point of the conne...

Embodiment 2

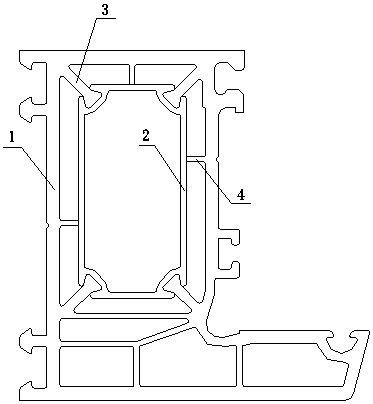

[0042] A door and window profile composited with plastic and reinforced lining, comprising an outer plastic layer 1 and a reinforced inner lining 2, the outer plastic layer 1 and the reinforced inner lining 2 are connected by a connecting bridge 3 .

[0043] Several supporting bridges 4 are arranged between the outer plastic layer 1 and the reinforced inner lining 2 .

[0044] A number of cavities are set up between the outer plastic layer 1 and the reinforced inner lining 2, and thermal insulation materials are injected into the cavities.

[0045] like Figure 13 , 14 As shown, the reinforced inner lining 2 is provided with several cavities 6, and the cavities 6 are filled with thermal insulation materials.

[0046] like Figure 5 , 6 , 7, the connecting bridge 3 and the reinforced inner lining 2 are made of the same material, the end of the connecting bridge 3 is provided with a child buckle, and the corresponding part of the outer plastic layer 1 is provided with a fema...

Embodiment 3

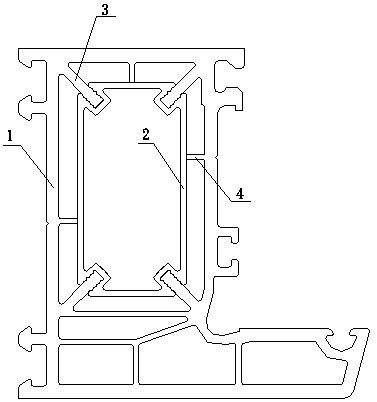

[0050] A door and window profile composited with plastic and reinforced lining, comprising an outer plastic layer 1 and a reinforced inner lining 2, the outer plastic layer 1 and the reinforced inner lining 2 are connected by a connecting bridge 3 .

[0051] Several supporting bridges 4 are arranged between the outer plastic layer 1 and the reinforced inner lining 2 .

[0052] A number of cavities are set up between the outer plastic layer 1 and the reinforced inner lining 2, and thermal insulation materials are injected into the cavities.

[0053] like Figure 13 , 14 As shown, the reinforced inner lining 2 is provided with several cavities 6, and the cavities 6 are filled with thermal insulation materials.

[0054] like Figure 11 As shown, the reinforced lining 2 is provided with a combination hole 5 . like Figure 10 As shown, the connecting bridge 3 and the outer plastic layer 1 are integrally made of the same material, and the connecting bridge 3 on the outer plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com