Engine Intake Cover and Its Opening and Closing System

An air intake and engine technology, applied in the direction of engine function, machine/engine, mechanical equipment, etc., can solve the problems of over-opening time of the cover and the failure of the cover to meet the sealing requirements, so as to prevent airflow from entering the engine intake. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

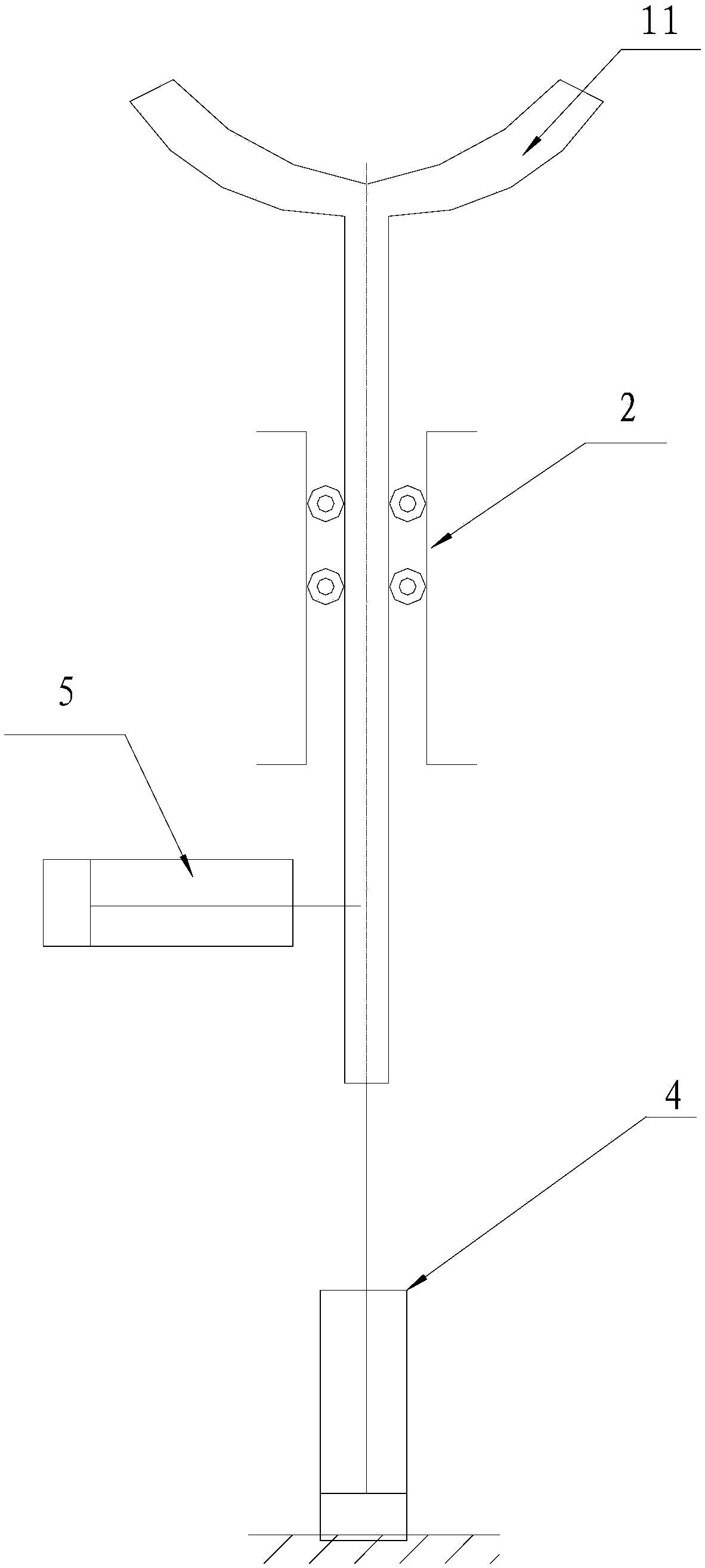

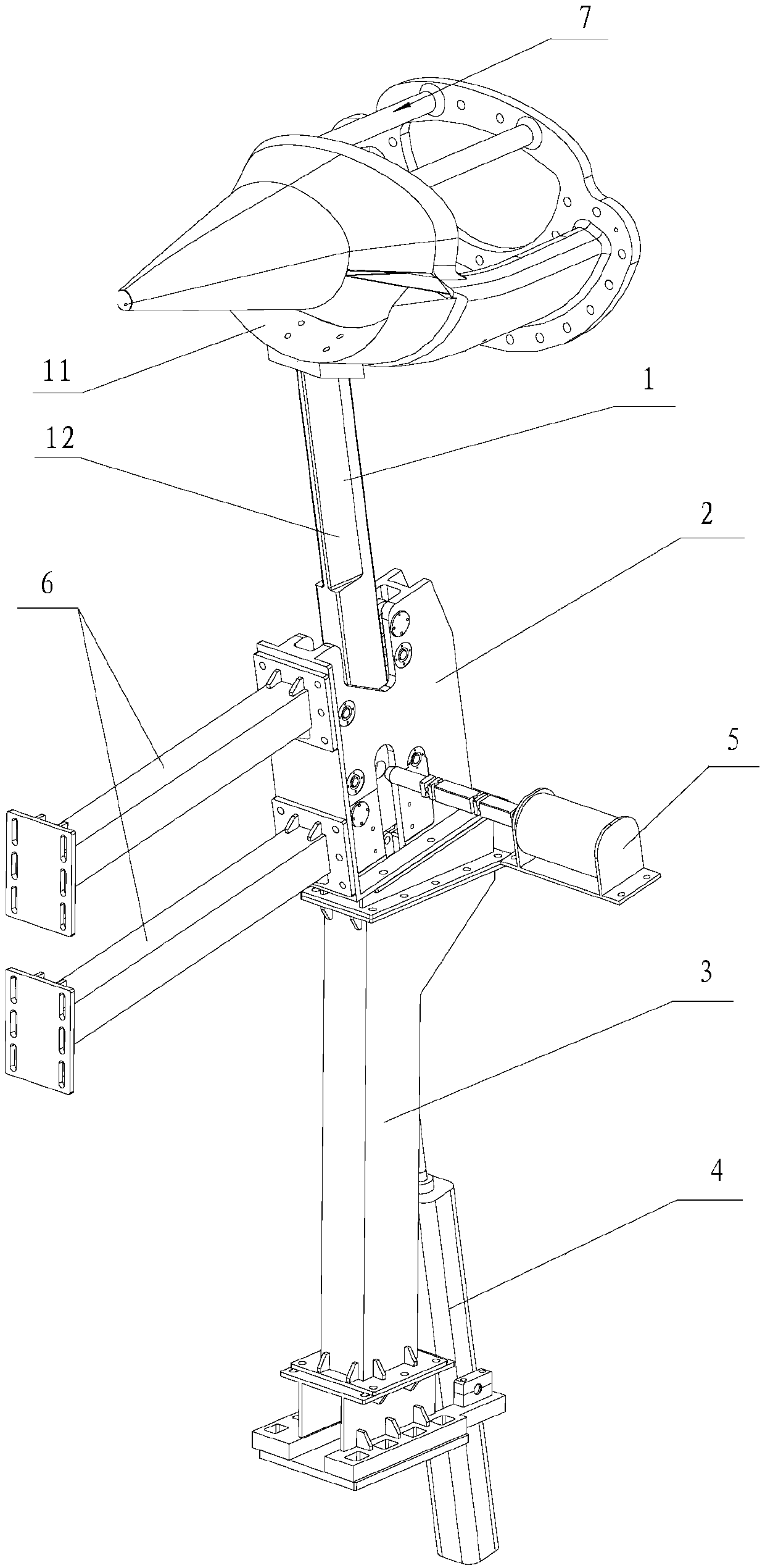

[0035] Such as figure 2 As shown, the engine intake port blocking cover opening and closing system provided by the present invention includes a blocking cover 1 , a rolling chute 2 , a first support seat 3 , a power cylinder 4 and a locking cylinder 5 .

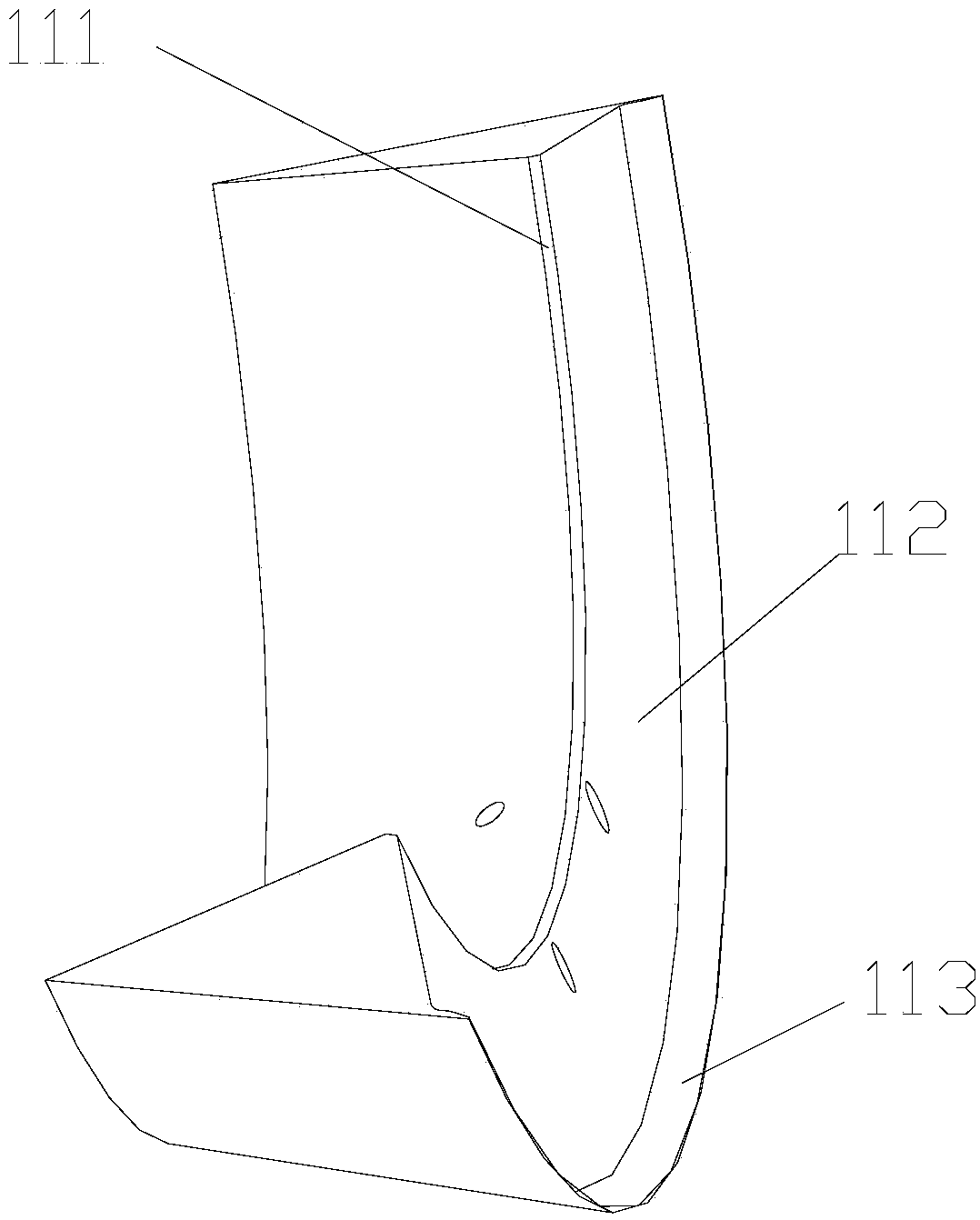

[0036] The plug cap 1 includes a plug head 11 and a connecting rod 12 . The structure of plugging head 11 is as image 3 As shown, the plugging head 11 is an arc-shaped structure formed by rotating the end face A around the central axis of the engine nose cone.

[0037] After the line segment OM and the line segment ON rotate around the central axis of the engine nose cone, an aerodynamic profile is formed.

[0038] After the curve C rotates around the central axis of the engine nose cone, the initial section of the curve C forms the first side 111, the middle section of the curve C forms the second side 112, and the end section of the curve C forms the third side 113; the shape of the first side 111 It is compatible with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap