Electrowetting display panel and control method thereof

An electrowetting display and electrowetting display technology, applied in static indicators, optics, instruments, etc., can solve the problems of low contrast, large loss of light transmittance, and affecting the display performance of transparent display screens, so as to improve the contrast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

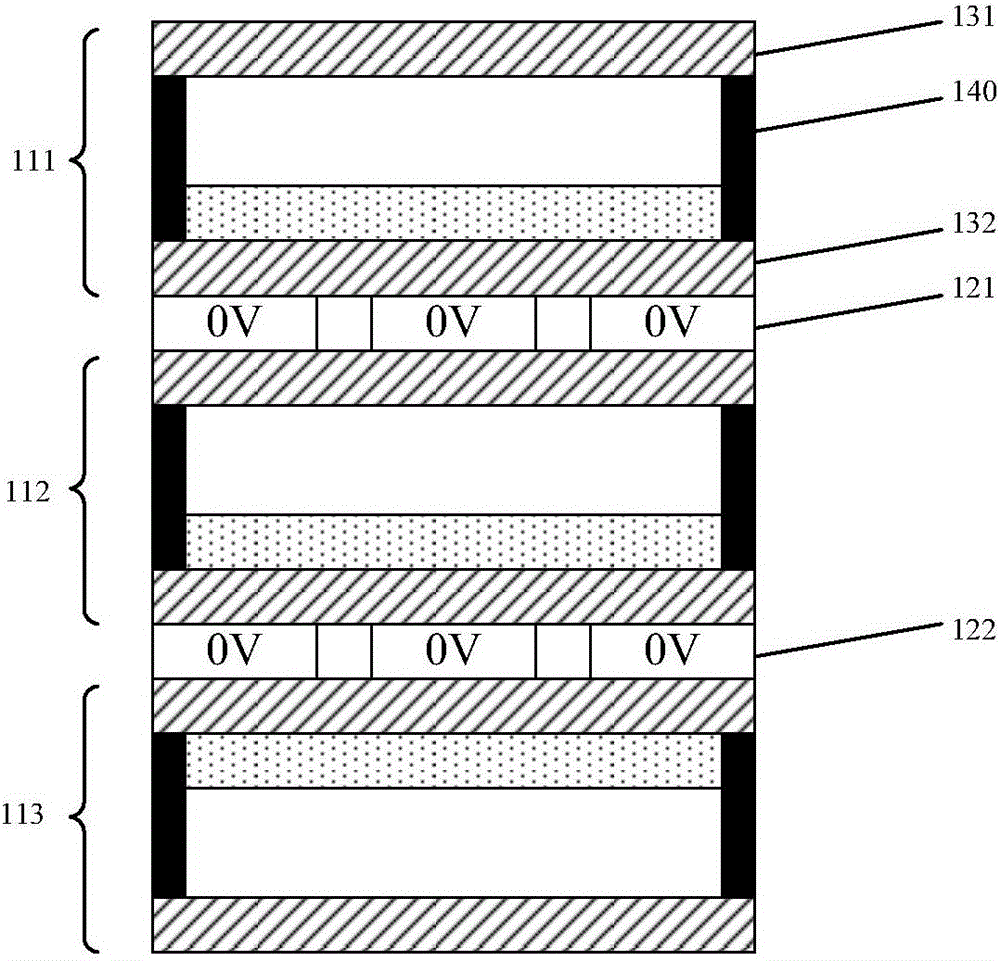

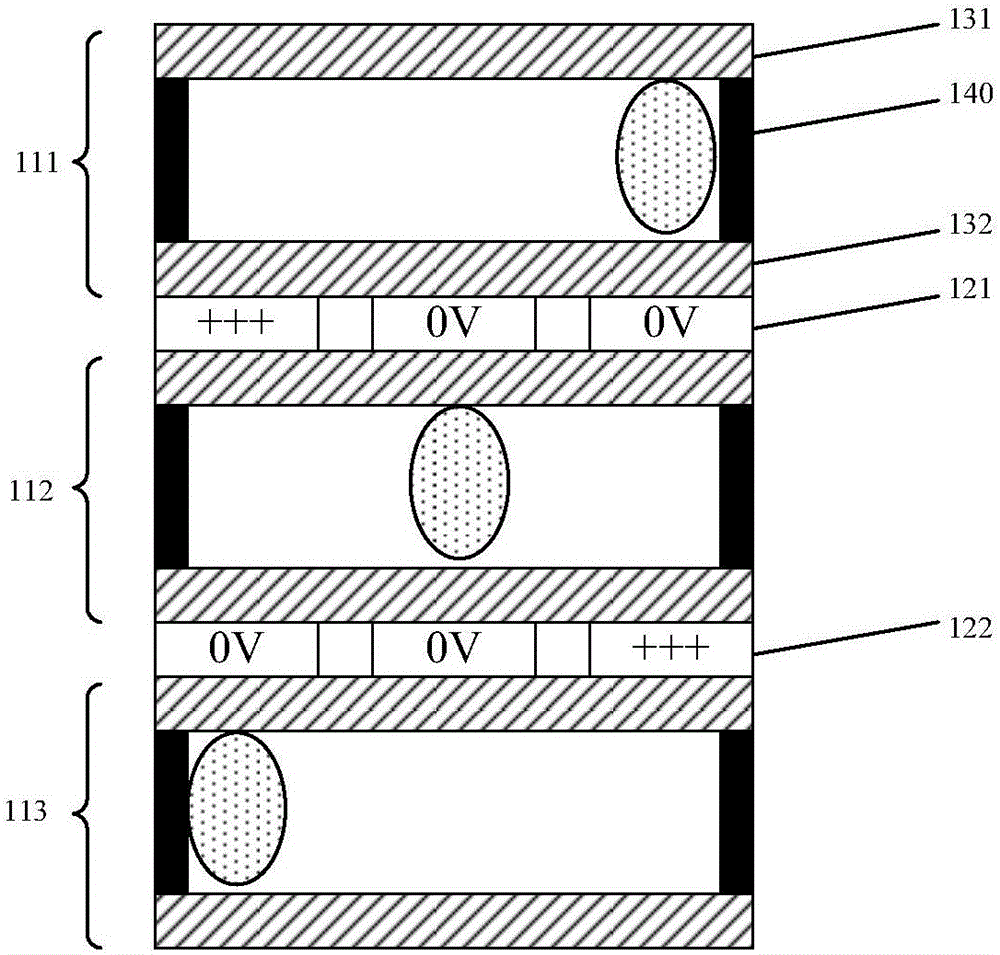

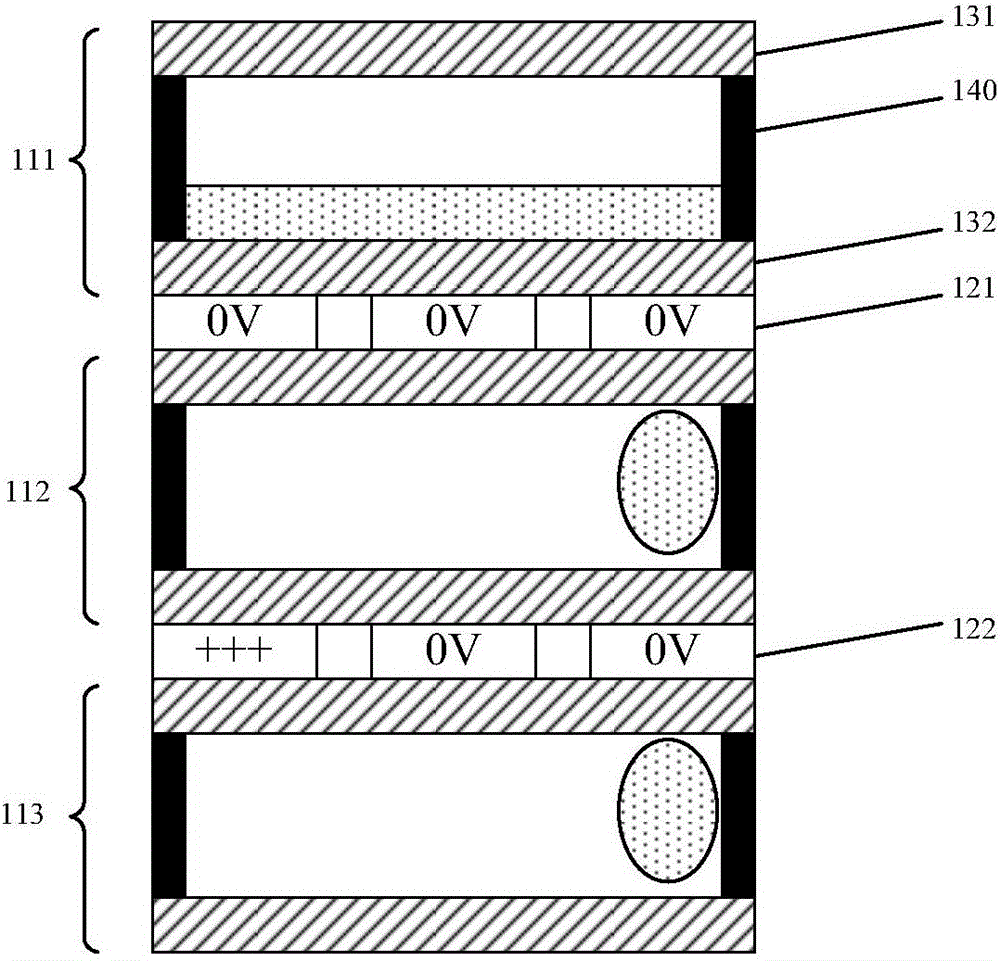

[0057] In this embodiment, the sub-pixel unit of the electrowetting display panel includes a laminated first liquid layer, a first electrode layer, a second liquid layer, a second electrode layer, and a third liquid layer, wherein each liquid layer includes a liquid , a first insulating layer, a second insulating layer, and a side wall, wherein the liquid is contained in a space surrounded by the first insulating layer, the second insulating layer, and the side wall, and the liquid includes a colored hydrophobic flow medium (i.e., non- Polar flow media, e.g., colored oily media, such as colored inks) and transparent hydrophilic flow media (i.e., polar flow media, such as water, aqueous solutions, or alcohols, such as electrolytic solutions), and The insulating layer adjacent to the electrode layer is a hydrophobic insulating layer.

[0058] In this embodiment, the electrowetting display panel can be transmissive, semi-transmissive or reflective, and can use backlight or ambien...

no. 2 example

[0086] In this embodiment, the sub-pixel unit of the electrowetting display panel includes a stacked first electrode layer, a first liquid layer, a second electrode layer, a second liquid layer, and a third electrode layer, wherein each liquid layer includes a liquid , a first insulating layer, a second insulating layer, and a side wall, wherein the liquid is contained in a space surrounded by the first insulating layer, the second insulating layer, and the side wall, and the liquid includes a colored hydrophobic flow medium (i.e., non- Polar flow media, for example, colored oily media, such as colored inks) and transparent hydrophilic flow media (i.e., polar flow media, such as water, aqueous solutions, or alcohols, such as electrolyte solutions), respectively The insulating layer adjacent to the first electrode layer and the third electrode layer is a hydrophobic insulating layer.

[0087] In this embodiment, the electrowetting display panel can be transmissive, semi-transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com