PID control method of applying variation trend of controlled variable

A technology of changing trends and controlled quantities, applied in the field of PID control, it can solve the problems of lag, large oscillation, and overshoot of PID control, improve control accuracy and smoothness, reduce the number and amplitude of overshoot, and prolong service time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

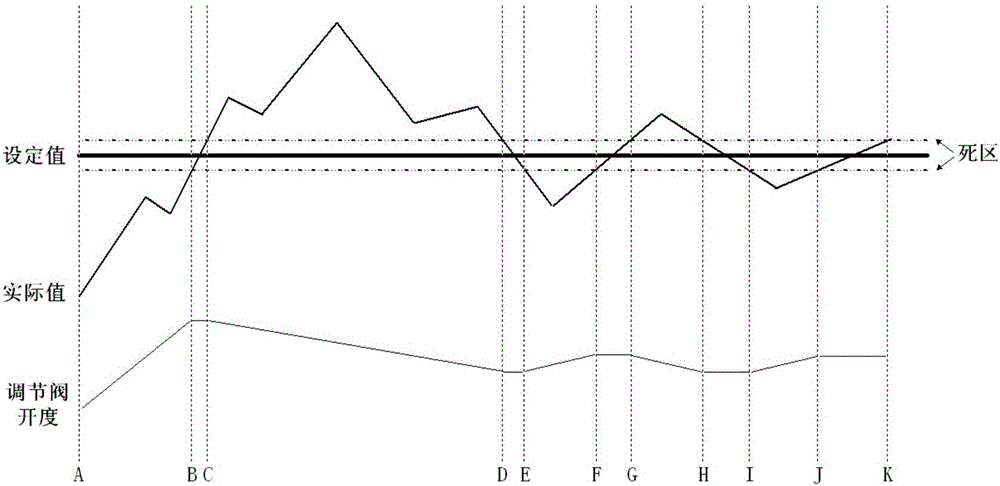

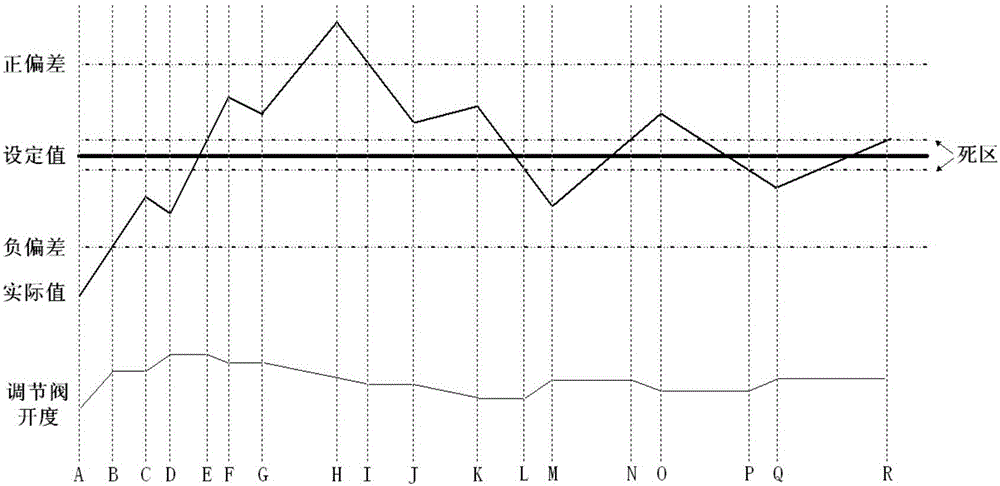

[0025] see figure 2 , a PID control method using a variation trend of a controlled quantity, comprising the following steps:

[0026] S1) Setting the dead zone parameter and the set value of the controlled quantity;

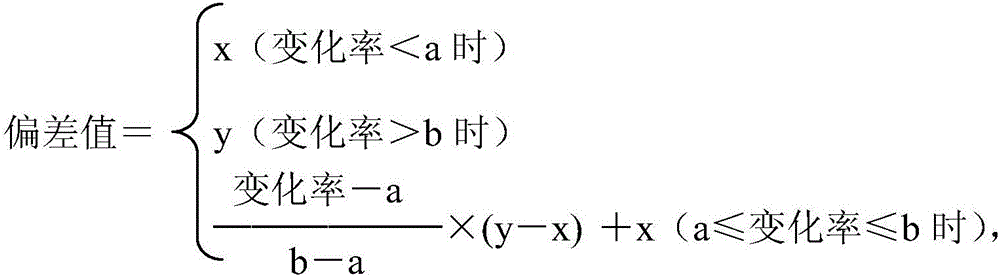

[0027] S2) obtain the actual value of the controlled quantity by data acquisition, calculate the rate of change of the controlled quantity actual value, calculate the positive and negative deviation value for trend judgment according to the rate of change; step S2) when the controlled quantity actual value When the value of the rate of change is large, the value of the selected positive and negative deviation is also large; when the value of the rate of change of the actual value of the controlled variable is small, the value of the selected positive and negative deviation is also small. Calculate reasonable positive and negative deviation values for trend judgment according to different rates of change. Positive deviation value = set value + deviation value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com