Anti-loosening and anti-rotation structure for threaded connection

A threaded connection and anti-rotation technology, which is applied in the direction of connection, parts of connecting devices, devices for connecting/disconnecting connecting parts, etc., can solve the problems of difficult insertion of connectors, and achieve the effect of easy processing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

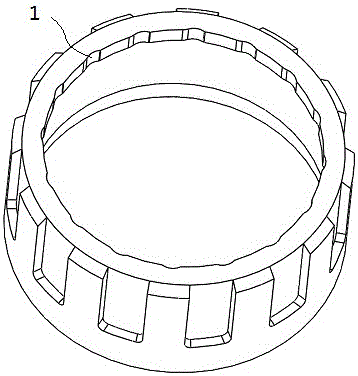

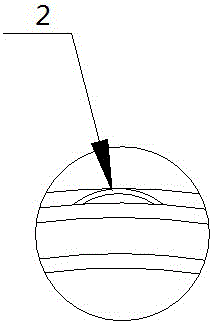

[0027] Such as Figure 4 As shown, the connector of the present invention includes a connecting outer sleeve and a connecting inner sleeve, the connecting inner sleeve is inserted into the connecting inner sleeve and the locking structure of the locking structure can make the connecting inner sleeve and the connecting outer sleeve rotate with each other, and The connecting inner cover and the connecting outer cover cannot fall off each other.

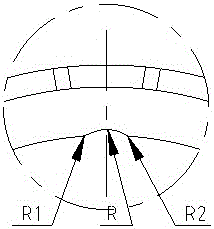

[0028] The key point of the present invention lies in the ingenious setting. The grooves of the connecting sleeve have circular arcs with different radii, and the resistance is controlled by the size of the circular arcs, so that the resistance of the connector is small when it is screwed together, which is convenient for installation and operation. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com