Methods for sealing, detection and marking leaks in structural enclosures

一种围护体、漏缝的技术,应用在远程密封工艺领域,能够解决不能明显影响烟气、时间和劳动力成本高、空气流动慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

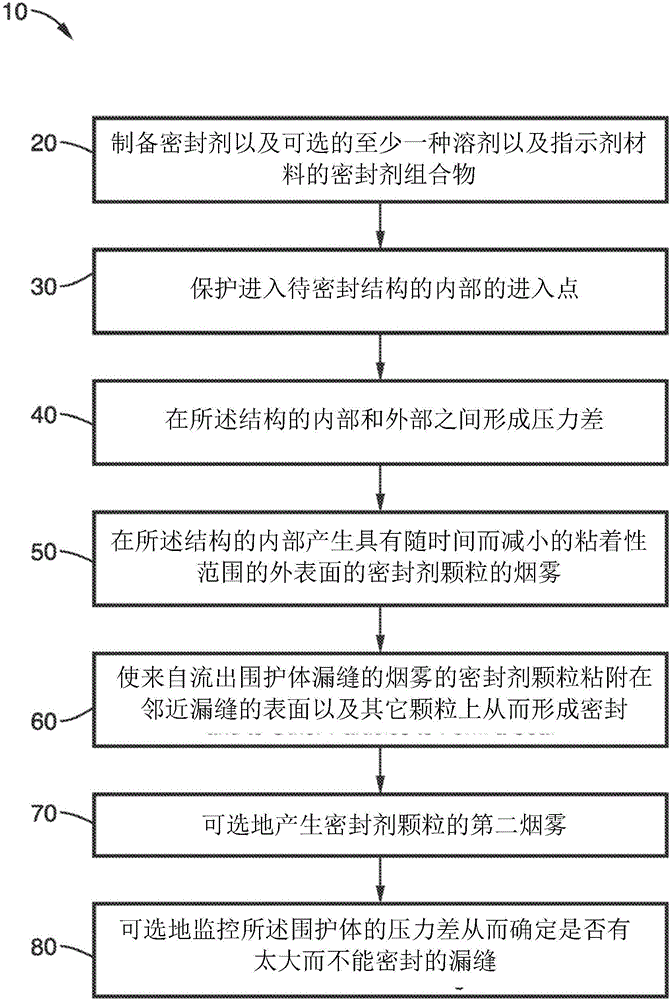

Method used

Image

Examples

example 1

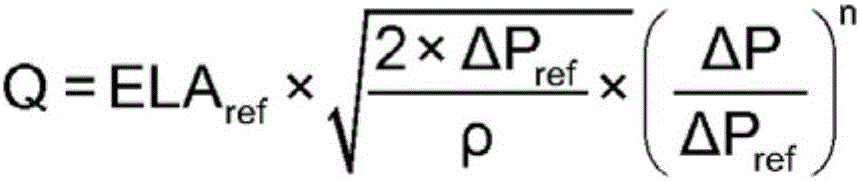

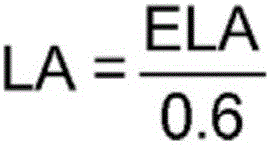

[0069] To illustrate the principle of operation of the device and sealing method, an enclosure measuring 8 feet by 8 feet by 4 feet (2.4m by 2.4m by 1.2m) was constructed for experimental testing with 12 inch by 12 inch (30 cm by 30 cm) leak panels in various locations on the shell. The approximate size of each slat in the panel is 0.1 to 0.12 inches x 10 inches x 0.125 inches (2.5 to 3mm x 25cm x 3mm) (H x W x D) and there are 6 leaks on each slatted panel seam. The height and width (0.125 to 0.12 inches (2.5 to 3 mm)) of each leak is meant to represent a typical crack in the building envelope, but the depth (0.125 inches (3 mm)) is deeper than expected to be found in a building The depth is much shorter. The total measured leakage of all panels is approximately 41 square inches (260cm 2 ) of the open drain area. A 14 inch (36 cm) diameter hole was also used as an injection site to introduce sealant fumes near the top of the enclosure.

[0070] The performance of the rem...

example 2

[0082] To further demonstrate the principle of operation of the device and sealing method, field tests were carried out during the drywall phase of construction and on empty existing dwellings. Based on laboratory and field test results, aerosol particles can be used to seal leaks in building envelopes.

[0083] Initial full-scale experiments with aerosol-based sealing techniques were conducted using existing aerosol catheter sealing techniques and tested in the laboratory experiments described in Example 1. Subsequent full-scale tests use multiple aerosol injection points with airless atomization and compressed air or fans to disperse sealant fumes into the structure. However, no carrier gas is required.

[0084] Access points in the room to be tested, such as windows, doors, and nozzles, are protected with substantially air-tight barriers such as tape or plastic sheets so that a pressure differential can be created in the structure and the access points are not sealed durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com