Embroidery machine able to sew cord material

A sewing machine and embroidery technology, which is applied to sewing machine components, thread hooks for sewing machines, and automatically controlled embroidery machines, etc., can solve the problems of complex mechanical mechanisms and adjustment needs man-hours, etc., and achieve the effect of simple structure and excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

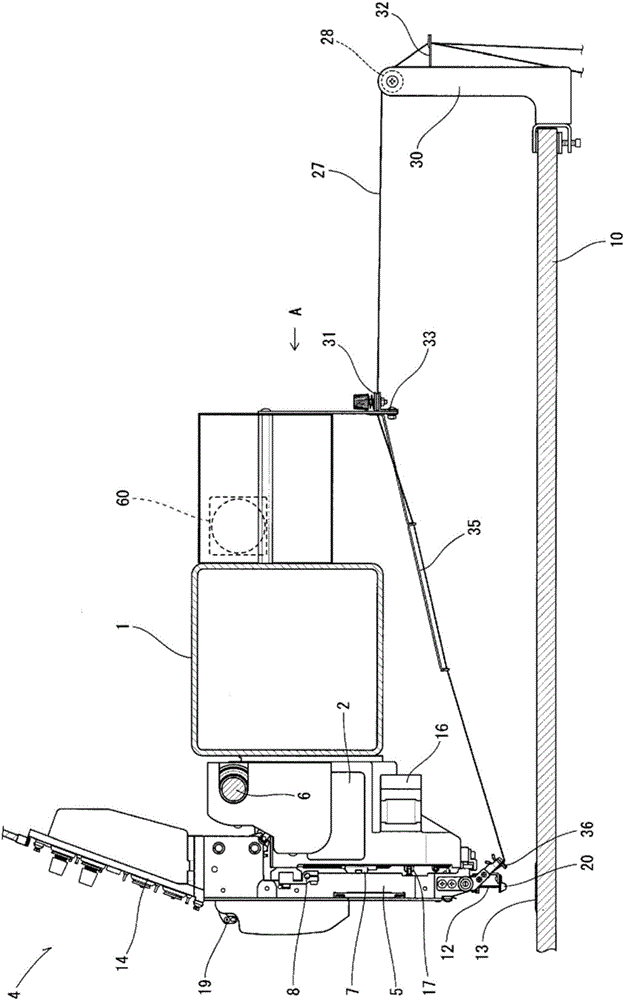

[0023] Embodiments of the present invention will be described in detail below with reference to the drawings.

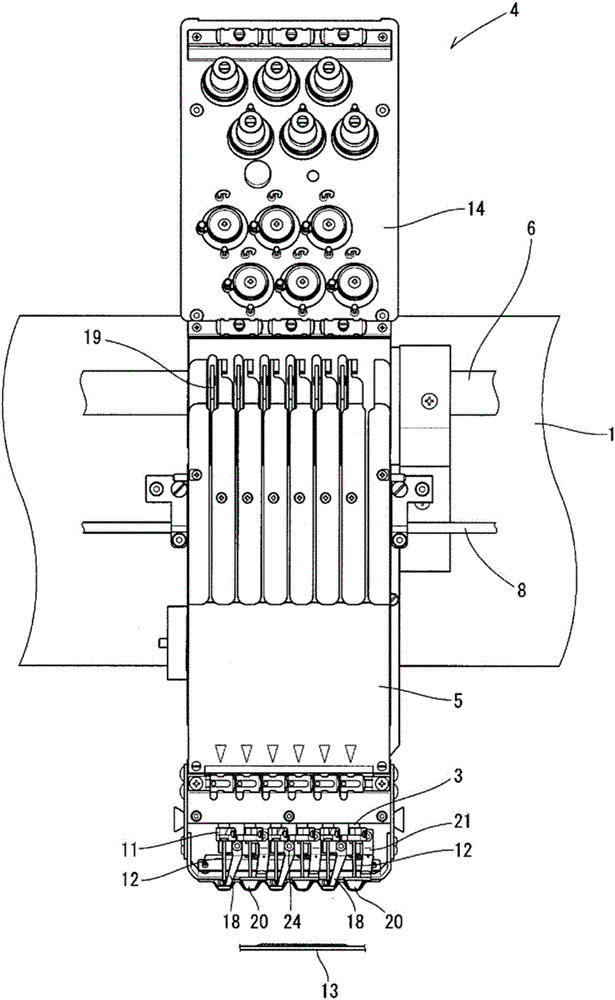

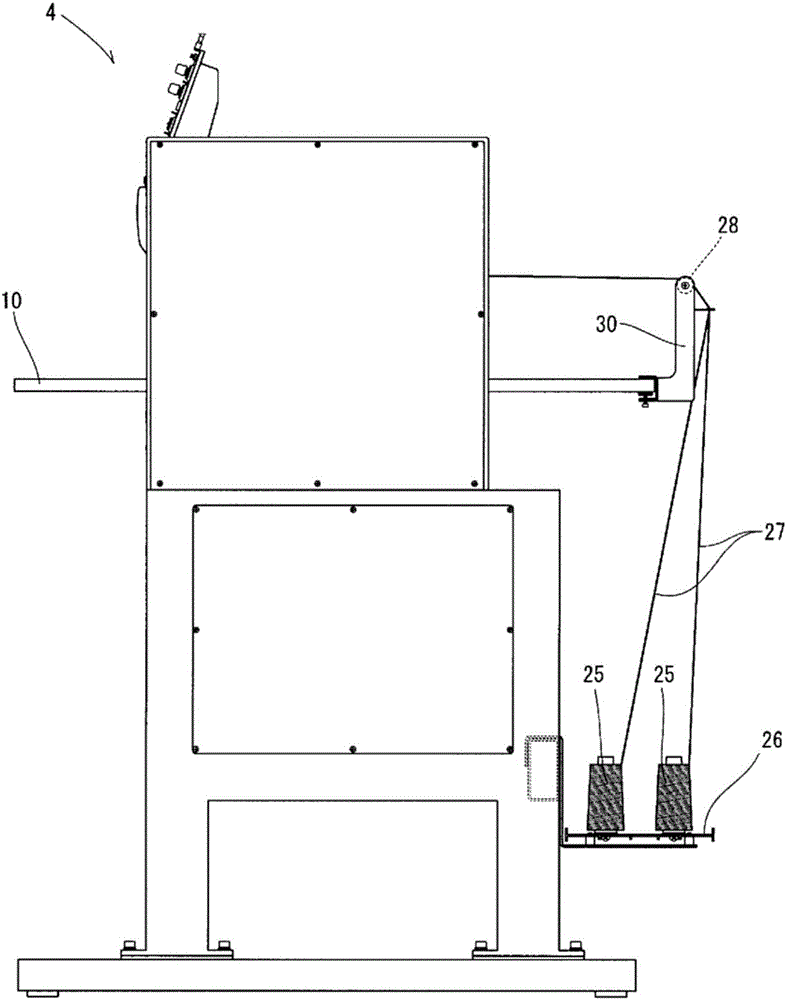

[0024] figure 1 It is a front view of one embroidery head 4 of the multi-head embroidery sewing machine. On the front surface of the sewing machine arm 2 attached to the front surface of the main body frame 1, a needle bar case 5 is slidably supported in the left-right direction. A plurality of (six in the figure) needle bars 3 are supported on the needle bar case 5 so as to be able to move up and down freely. Each needle bar 3 is arranged so that its axial direction extends in the vertical direction (vertical direction), and a sewing needle 12 is attached to each lower end via a needle holder 11 .

[0025] A sliding shaft 8 is provided through the needle bar case 5 , and the sliding shaft 8 is driven by a motor to slide, so that the needle bar case 5 slides in the left-right direction. Any one of the six needle bars 3 is positioned at the operating position corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com