Drilling and planting machine

A technology of drilling pits and reducers, which is applied in application, excavation/covering trenches, planting methods, etc., can solve the problems of high labor intensity and low efficacy, and achieve the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

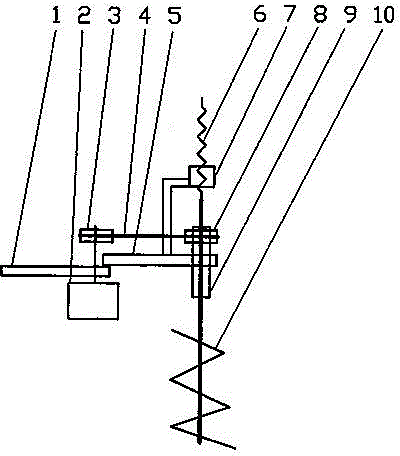

[0009] in figure 1 The reducer (2) is installed on the agricultural frame (1), the transmission wheel (3) is fastened on the reducer (2), and the transmission belt (4) and the driven wheel (8) are connected together to transmit power. . The auger lifting frame (5) is fastened to the agricultural frame (1), the screw nut (7) is fastened to the auger lifting frame (5), the screw rod (6) is set in the middle, and the inner square and outer tube (9) The auger (10) set in the middle is blocked and operated by the driven wheel (8) on the auger lifting frame (5). The upper half of the auger (10) is installed in the inner cavity of the screw nut (7) to move up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com