Azoxystrobin and cyproconazole compounded suspending agent and preparation method thereof

A technology of cyproconazole and suspending agent, which is applied in the field of pesticides, can solve problems such as high cost of use, food safety, and environmental pollution, and achieve the effects of safe use, improved drug efficacy, and expanded antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

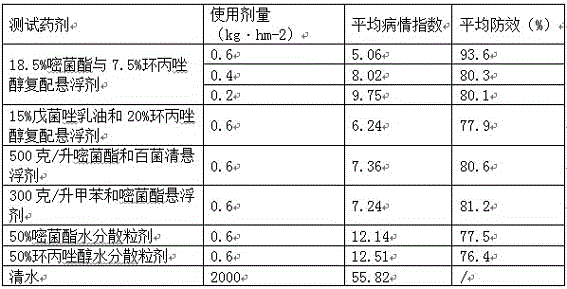

Examples

Embodiment 1

[0028] The compounded suspension concentrate of azoxystrobin and cyproconazole in this embodiment contains the following components in mass percentage: 18.5% of the original drug of azoxystrobin, 7.5% of the original drug of cyproconazole, and the wetting and dispersing agent alkane Sodium phenyl sulfonate 3%, dispersant calcium lignosulfonate 2%, antifreeze agent ethylene glycol 2.5%, adsorbent superfine white carbon black 0.5%, preservative sodium benzoate 0.1%, thickener xanthan gum 0.15% %, defoamer 1%, and the balance is water.

[0029] Quantitatively weigh each component of the xanthan gum in the formula and mix it with water to 95%, mix it well and place it in a sand mill for grinding, and grind it to 3-5 μm after 4 hours to obtain a preliminary formed suspension product, and then mix the xanthan gum The original gum was mixed with water to 5%, and added to the initial product of the suspension. After stirring for 2 hours with a mixer, a suspension concentrate composed ...

Embodiment 2

[0032] The compounded suspension concentrate of azoxystrobin and cyproconazole in this embodiment, the suspension contains the following components in mass percentage: 15% of the original drug of azoxystrobin, 10% of the original drug of cyproconazole, a wetting dispersant Base phenol polyoxyethylene sodium sulfate 3%, dispersant sodium lignosulfonate 2%, antifreeze agent ethylene glycol 2.5%, adsorbent superfine white carbon black 0.5%, preservative sodium benzoate 0.1%, thickener yellow Raw gum 0.15%, defoamer 1%, the balance is water.

[0033] Quantitatively weigh each component of the xanthan gum in the formula and mix it with water to 95%, put it in a sand mill after mixing, and grind it to 3-5 μm after 4 hours to obtain a preliminarily formed suspension product. The original gum was mixed with water to 5%, and added to the initial product of the suspending agent, and after stirring for 2 hours with a mixer, a suspending agent compounded with 15% azoxystrobin and 10% cypr...

Embodiment 3

[0036] The compounded suspension concentrate of azoxystrobin and cyproconazole in this embodiment, the suspension contains the following components in mass percentage: 20% of the original drug of azoxystrobin, 5% of the original drug of cyproconazole, wetting and dispersing agent alkanes Sodium phenyl sulfonate 3%, dispersant sodium lignosulfonate 2%, antifreeze agent ethylene glycol 2.5%, adsorbent superfine white carbon black 0.5%, preservative sodium benzoate 0.1%, thickener xanthan gum 0.15% %, defoamer 1%, and the balance is water.

[0037] Quantitatively weigh each component of the xanthan gum in the formula and mix it with water to 95%, mix well and place it in a sand mill for grinding, and grind it to 3-5 μm after 4 hours to obtain a preliminary formed suspension product, and then mix the xanthan gum The raw gum was mixed with water to 5%, and added to the initial product of the suspending agent, and after stirring for 2 hours with a mixer, a suspending agent compounde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com