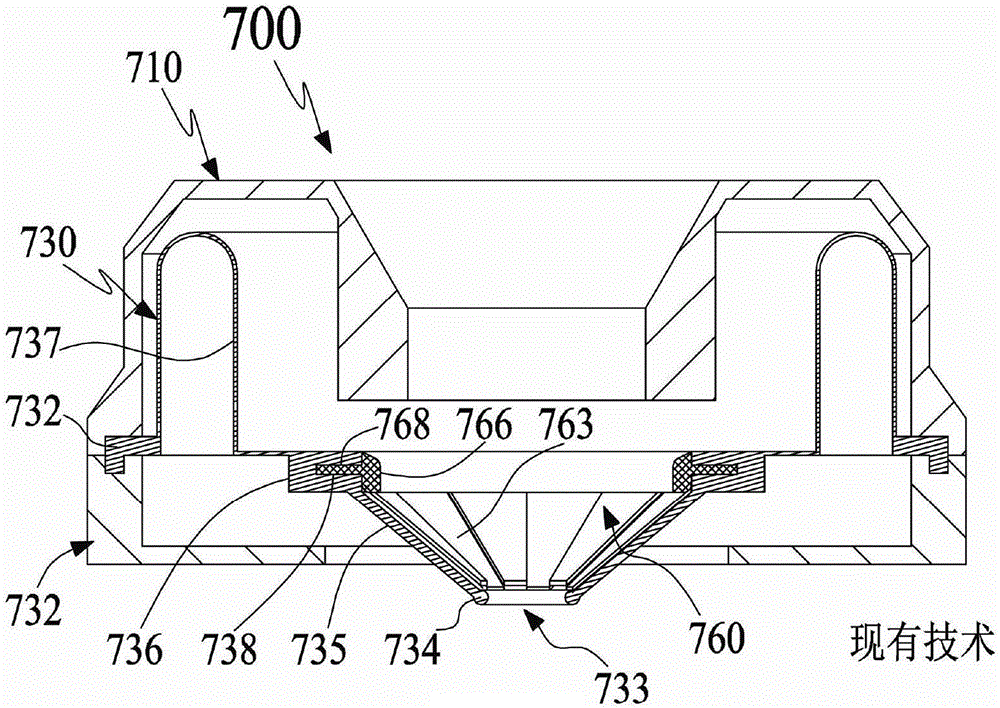

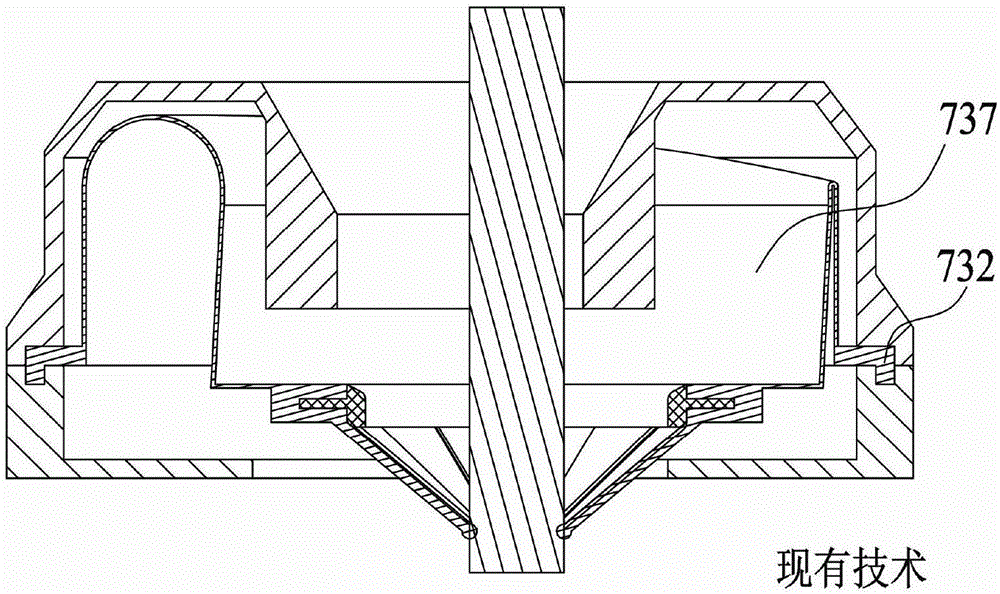

Puncture device sealing membrane containing multi-dimensional floating wrinkles

A technology of sealing film and puncture device, which is applied in the fields of puncture needle, puncture needle, medical science, etc., can solve the problems of increased production cost, complicated mold and high defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

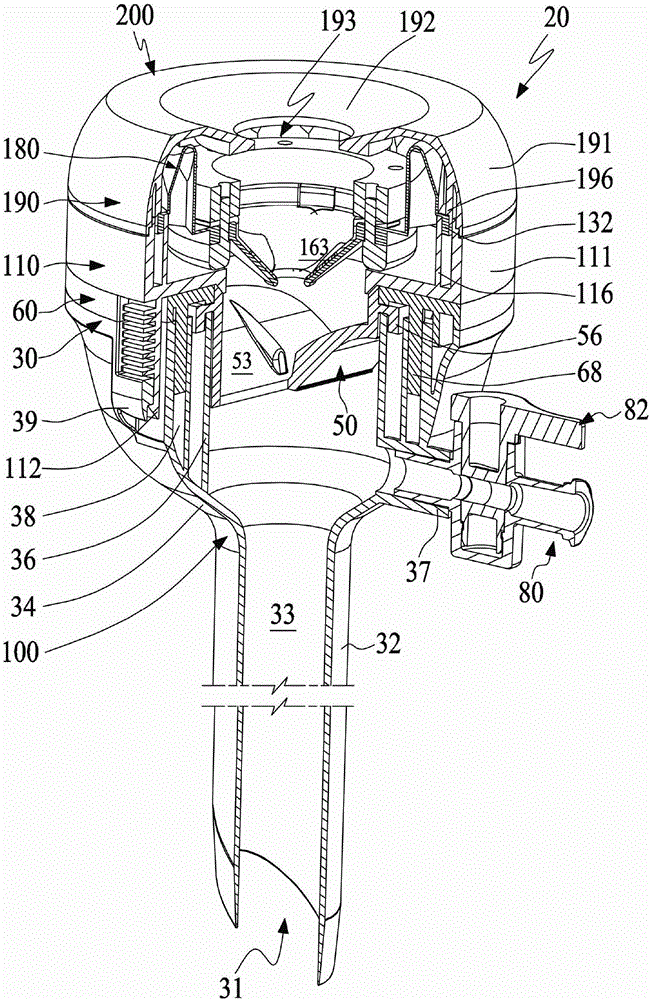

Examples

Embodiment 1

[0060] The cross-sectional shape of the radial folds 140 in Embodiment 1 is approximately U-shaped; while the cross-sectional shape of the radial folds 440 in Embodiment 4 is approximately V-shaped; Embodiment 4 and Embodiment 1 reduce the outer The radial pulling force when the floating part moves radially to the extreme position has similar effect.

[0061] It is easy for those skilled in the art to think that a reasonable rounded corner transition can avoid stress concentration or make deformation of certain regions easier. Due to the small size of the sealing film, especially the area near the sealing lip, such a small size, the shape of the sealing film looks very different with different chamfers. In order to clearly show the geometric relationship between elements, the examples described in the present invention are usually figures after the rounded corners are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com