Dust removal device for pyrophyllite crushing system

A technology of dust removal device and crushing system, which is applied in combination device, separation method, dispersed particle separation, etc., can solve the problem of dust affecting air quality, etc., and achieve the effect of avoiding flow to the atmosphere, saving cost and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

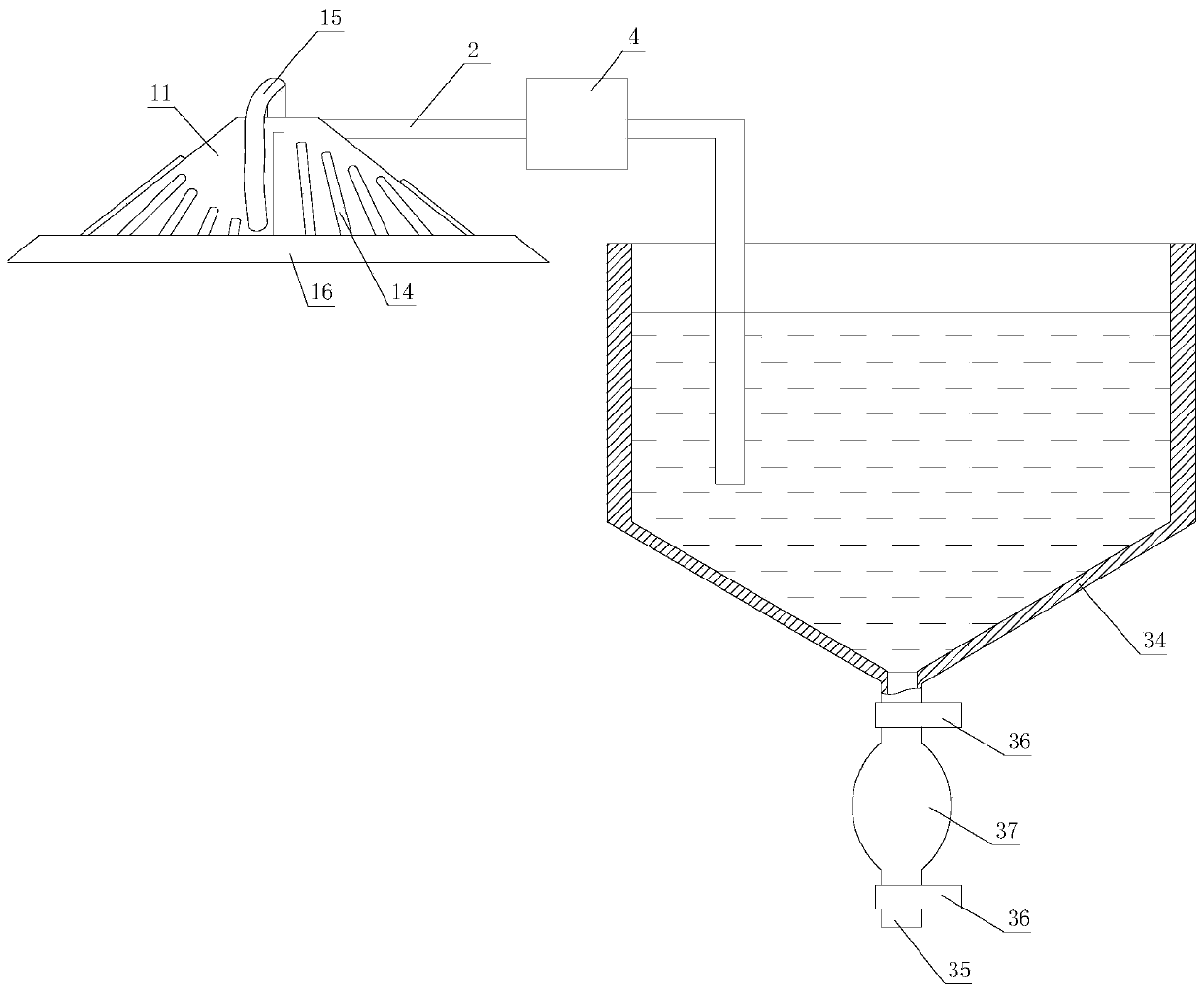

[0026] refer to figure 1 , The dedusting device for the pyrophyllite crushing system includes a dust collector, an air outlet pipe 2, an induced fan 4 and a water dust collector, and the induced fan 4 is arranged on the air outlet pipe 2.

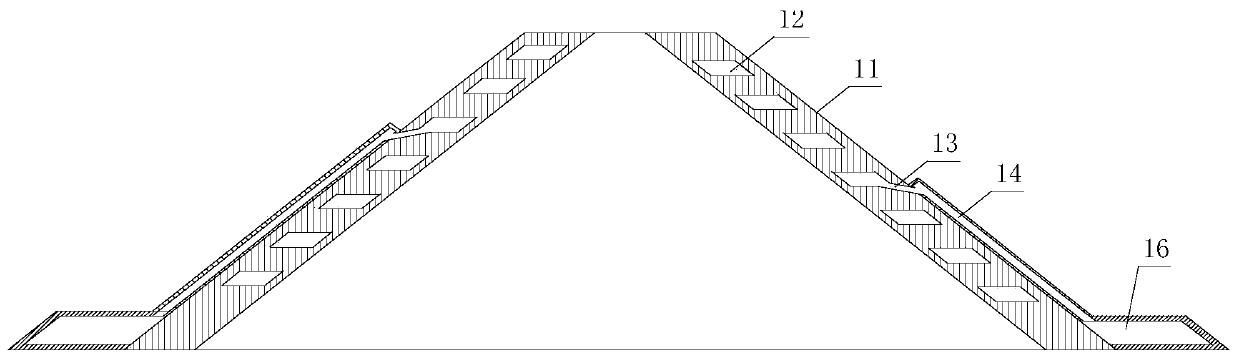

[0027] refer to figure 1 and figure 2 , the dust collector includes a body 11, a dust collection tank 16 and a connecting pipe 15. The body 11 is in the shape of a trumpet with a small upper part and a larger lower part. Connected dust discharge channels 13, each dust discharge channel 13 lower end is connected with a dust discharge pipe 14, each dust discharge pipe 14 lower end is connected with a dust collection groove 16, and the dust collection groove 16 surrounds the outer wall of the lower end of the body 11 .

[0028] refer to figure 1 , the water dust collector includes a water tank 34 and a storage pipe 35, the lower bottom surface of the water tank 34 is a tapered surface with a large upper part and a smaller lower part, the ...

Embodiment 2

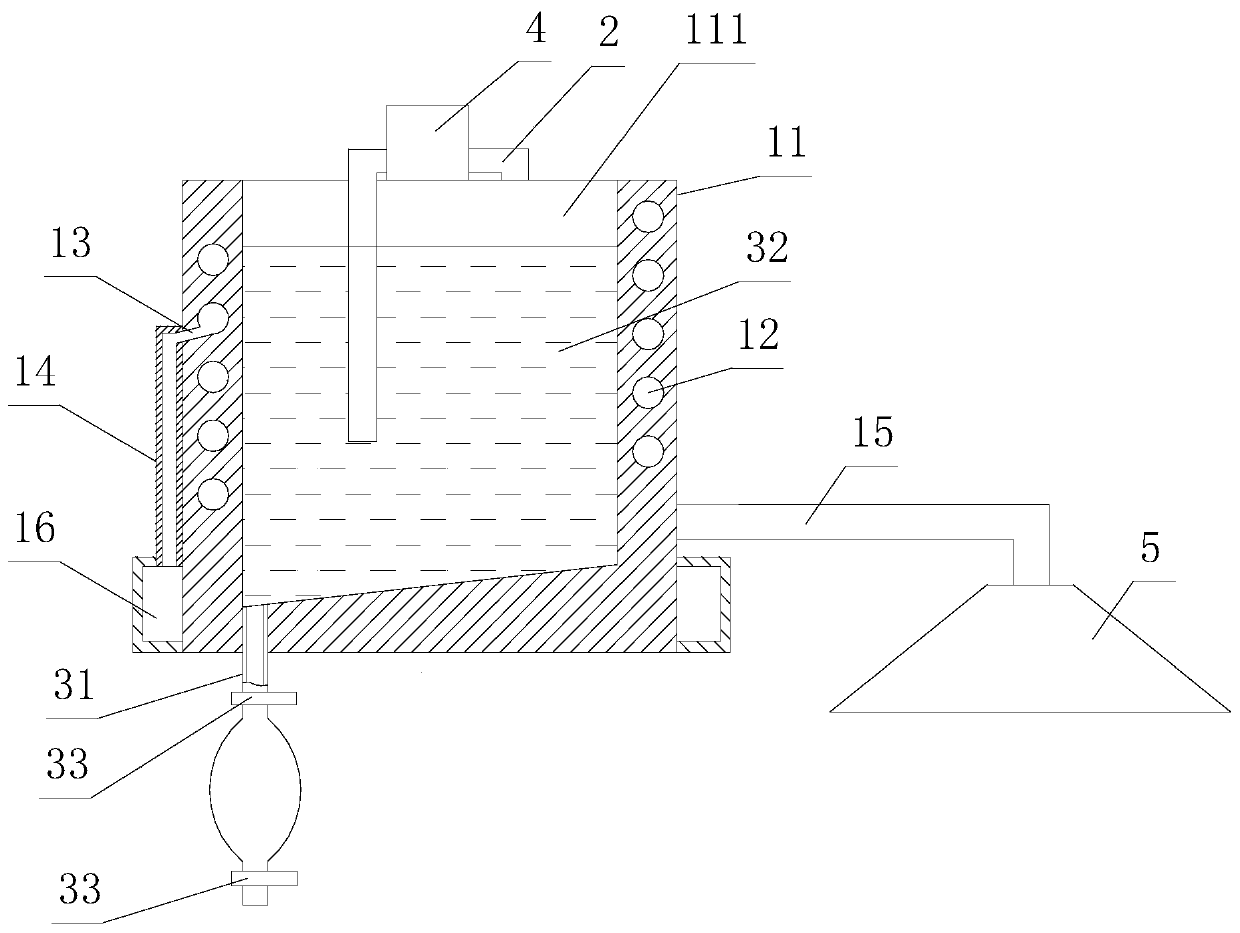

[0033] refer to image 3 and Figure 4 , the dedusting device for the pyrophyllite crushing system, including a dust collector, an air outlet pipe 2, an induced draft fan 4, a water dust collector and a dust collection cover 5, and the induced draft fan 4 is arranged on the air outlet pipe 2;

[0034] refer to image 3 and Figure 4 The dust collector includes a body 11, a dust collection tank 16 and a connecting pipe 15. The body 11 is cylindrical and has a cavity 111 with an upward opening. The body 11 is provided with a cylindrical spiral channel 12 arranged on the inner wall of the channel 12. There is a dust discharge channel 13 communicating with the channel 12, and the lower end of each dust discharge channel 13 is connected with a dust discharge pipe 14. on the outer wall of the

[0035] refer to image 3 , the channel 12 is provided with an air inlet and an air outlet, the air inlet is arranged at the lower end of the outer wall of the body 11, and the air outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com