Spraying foam desulfurization dust remover

A desulfurization dust collector and foam technology, applied in chemical instruments and methods, water/sludge/sewage treatment, use of liquid separation agents, etc., can solve the problems of inability to achieve dust removal effect, failure to meet sustainable development, waste of water resources, etc. , to prevent the diffusion of impurities, reduce foam, and slow down the flow rate of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

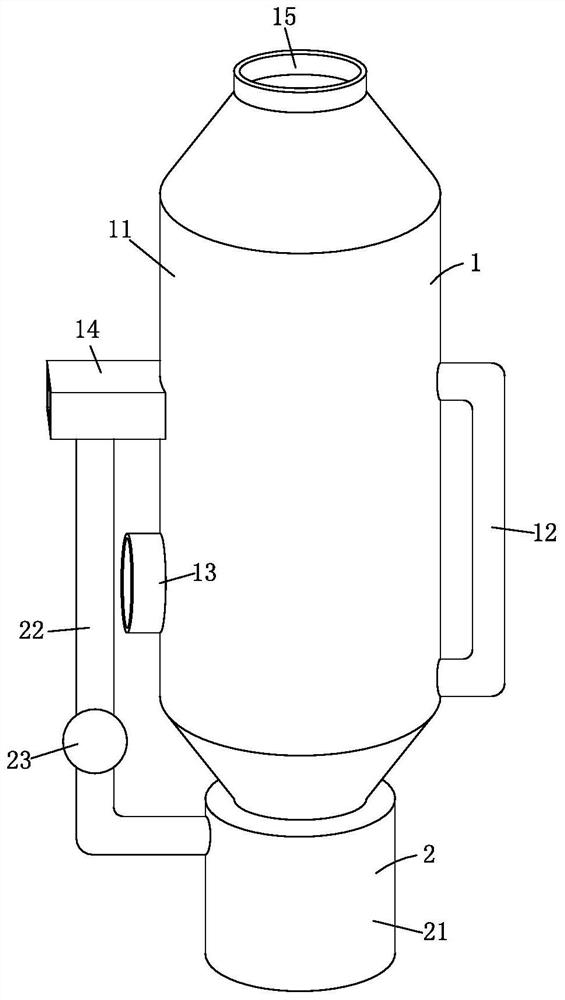

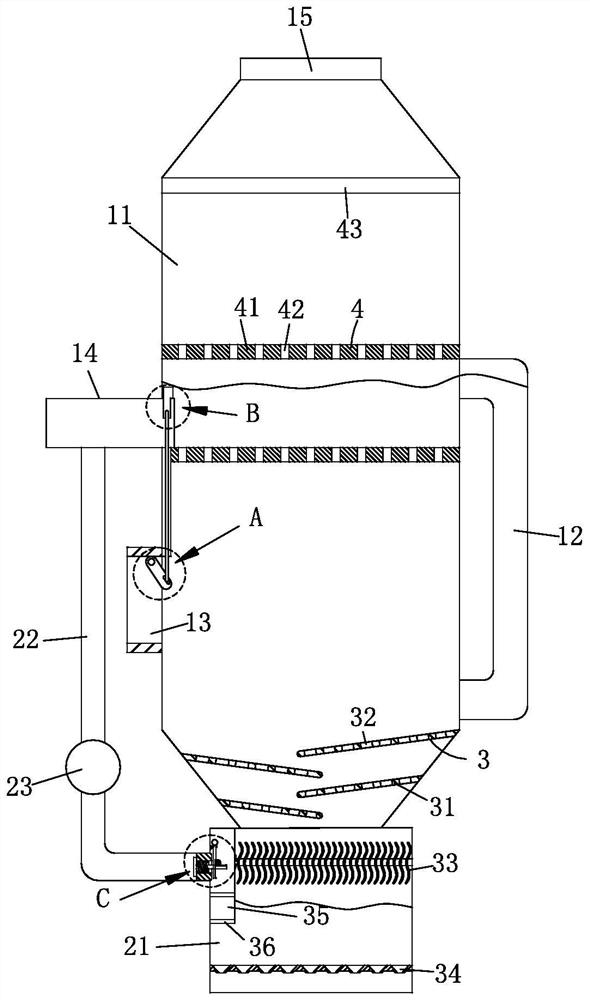

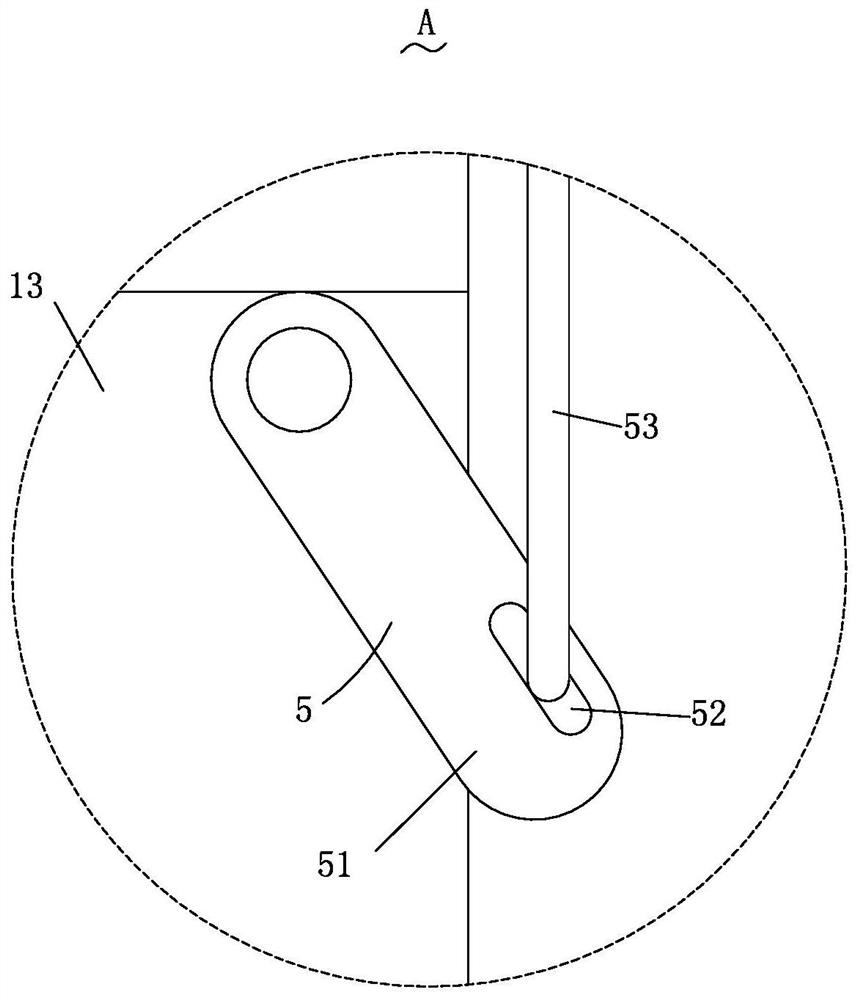

[0025] Such as Figure 1-Figure 6 As shown, a spray foam desulfurization dust remover according to the present invention includes a tank structure 1, a water treatment structure 2, a filter structure 3, a dust removal structure 4, a current limiting structure 5 and a foam resistance structure 6; for storage and The water treatment structure 2 for treating sewage is installed at the bottom of the tank structure 1; the filter structure 3 for filtering and precipitating sewage is installed inside the water treatment structure 2; Impurities and the dust removal structure 4 for making foam are installed inside the tank structure 1; the flow limiting structure 5 for adjusting the water flow is installed inside the tank structure 1; for preventing foam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com