Mobile smoke blast trapping device for furnace mixer

A mobile, mixed iron furnace technology, applied in the field of smoke and dust devices, can solve the problem of unsatisfactory dust removal and capture effect, and achieve good dust removal effect, easy to use, and high smoke capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

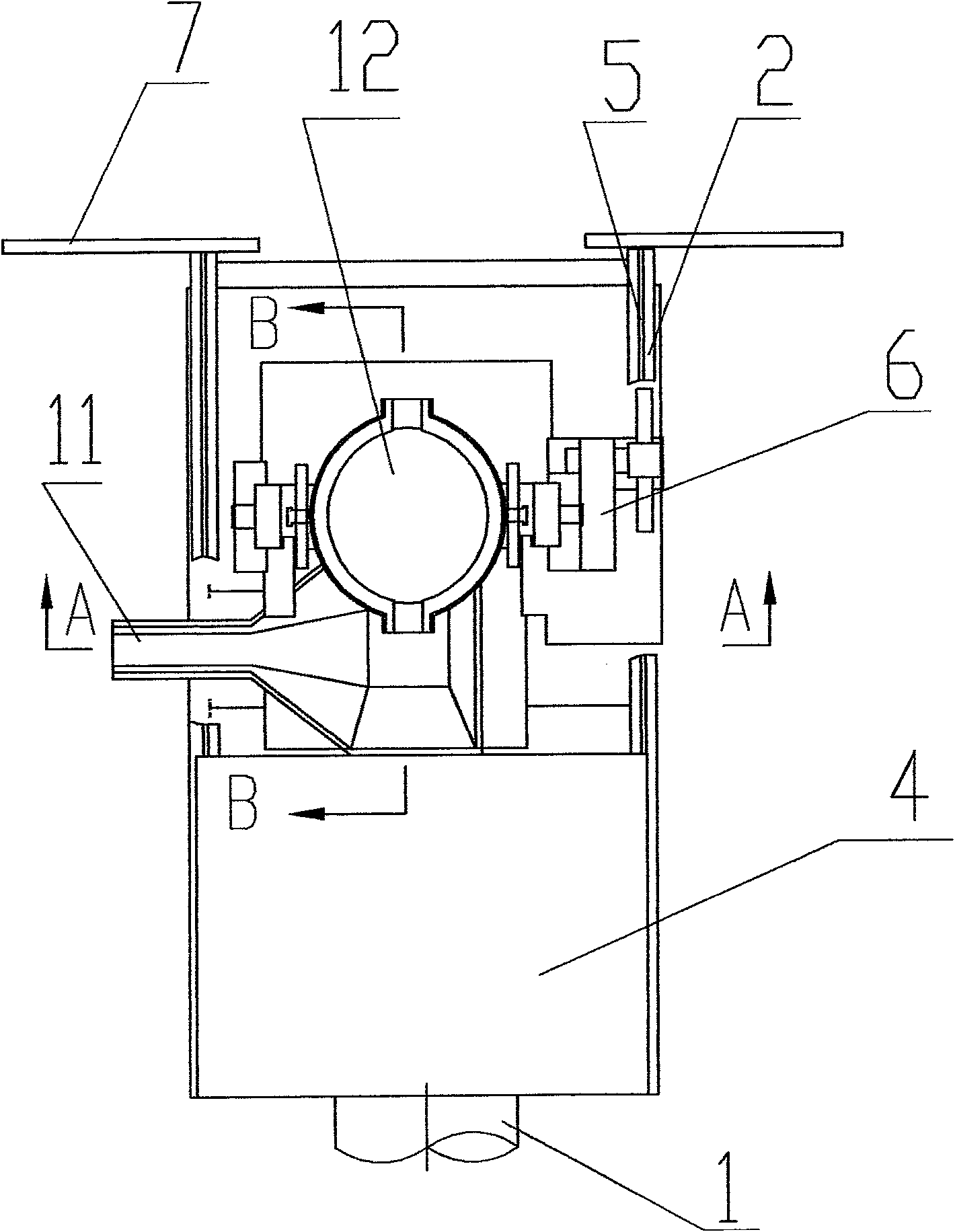

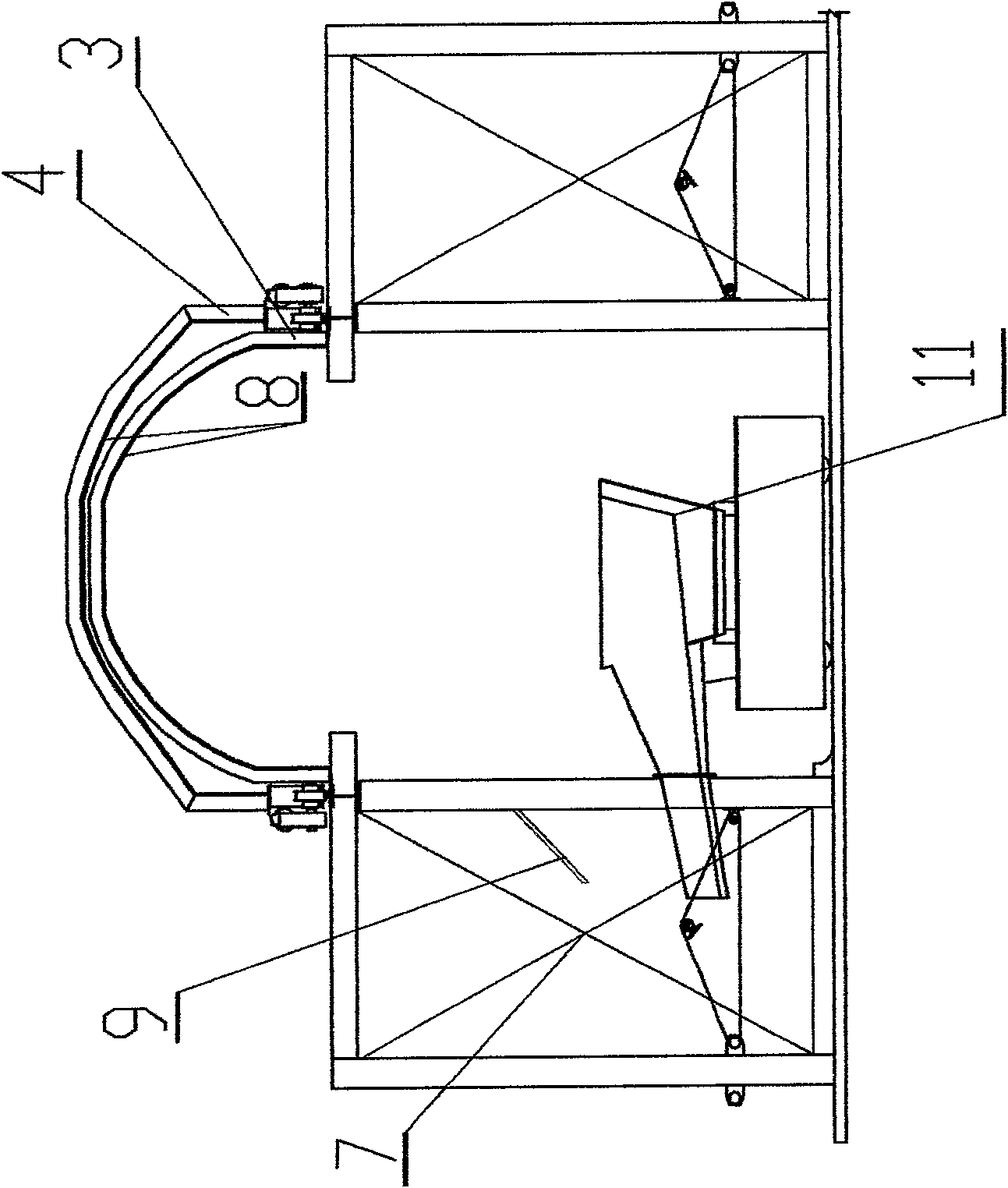

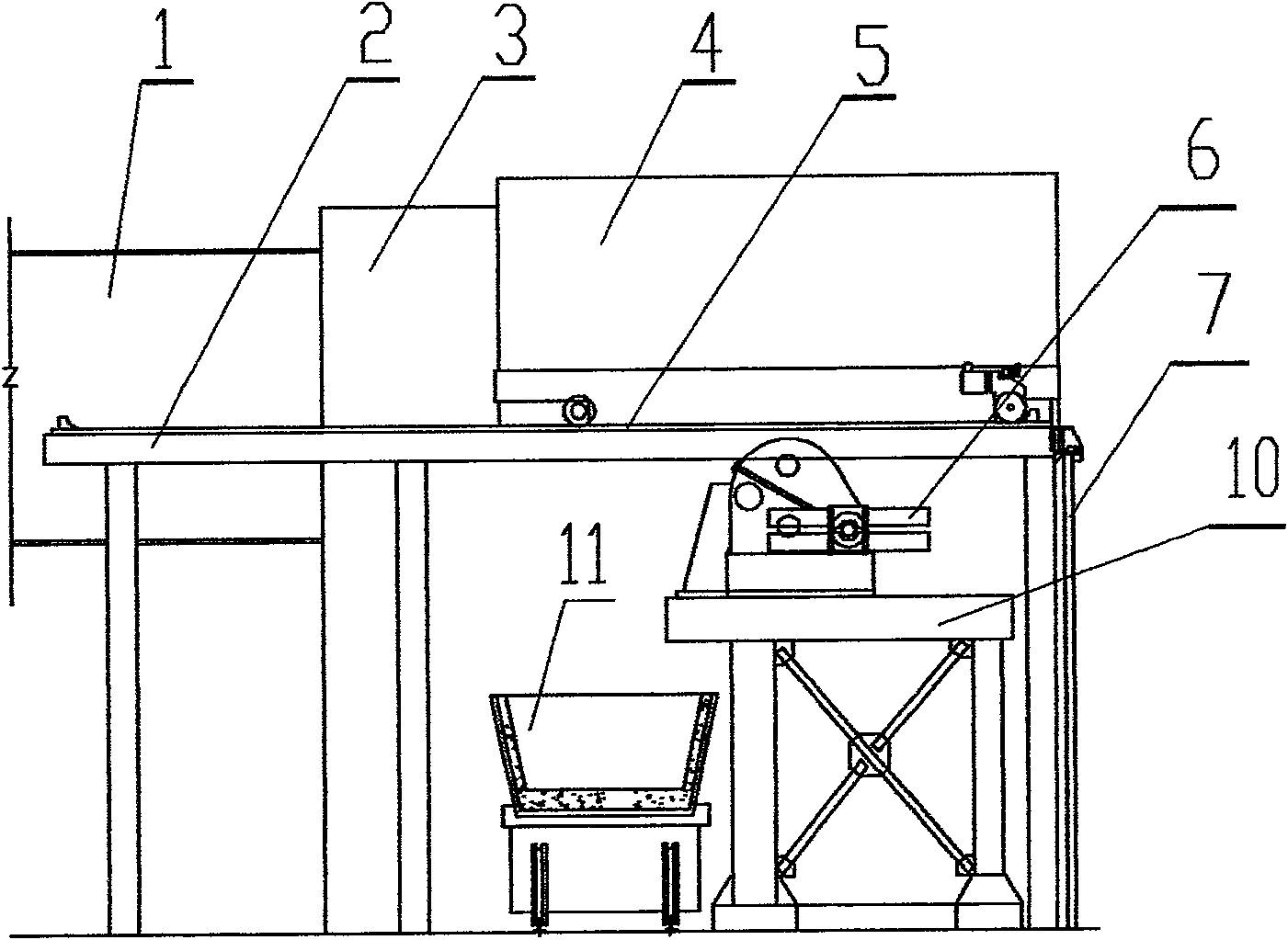

[0022] refer to image 3 , a mobile dust collection device for a mixed iron furnace, comprising a dust removal pipe 1, the mobile dust collection device for a mixed iron furnace also includes a bracket 2, a fixed fume hood 3 and a movable fume hood 4, wherein the fixed fume hood 3 It is installed on the support 2, and guide rail 5 is set on the support 2. The movable fume cover 4 can move along the guide rail 5, and can be combined with the fixed fume cover 3 to form an airtight dust removal cover. The molten iron tank tilting device is provided in the support 2. 6, and the dust removal pipe 1 is set on one side of the fixed fume hood 3; refer to figure 1 and figure 2 , one side of the support 2 is provided with a movable door 7, the movable door 7 is located on the same side of the support 2 as the movable hood 4, and the moving direction of the movable door 7 is perpendicular to the moving direction of the movable hood 4, the movable door 7 Can move left and right, facili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com