Experiment glass container cleaning and drying all-in-one machine

A glass container and all-in-one machine technology, applied in the direction of dryers, drying gas arrangement, local agitation dryers, etc., can solve the problems of high labor intensity and slow washing efficiency, achieve high work efficiency and realize the effect of batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below.

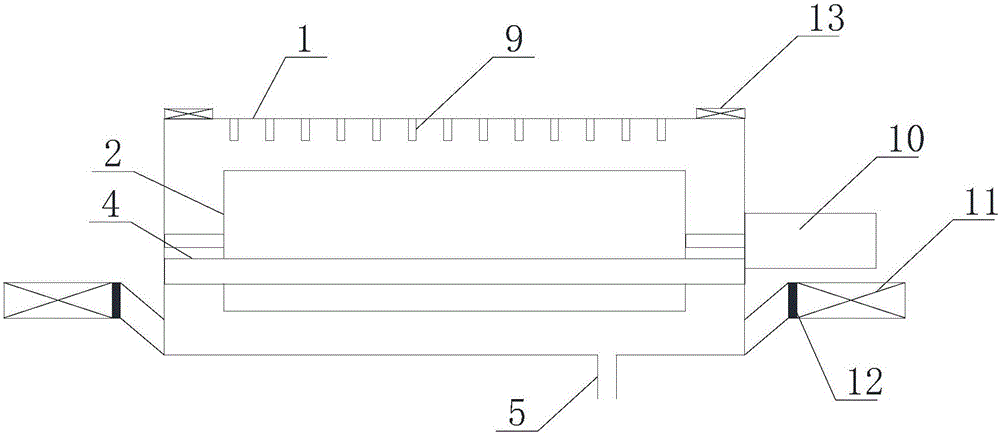

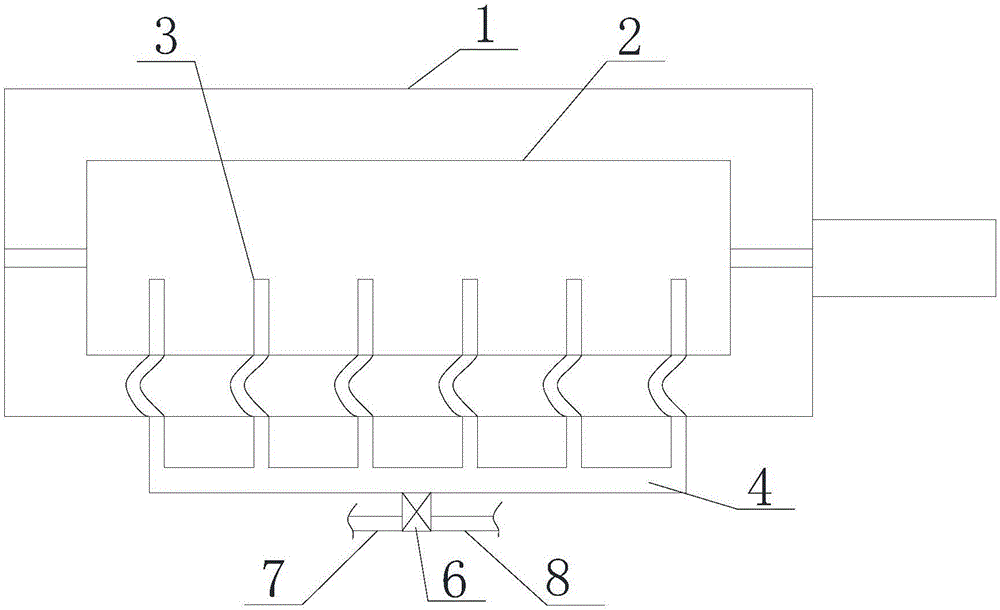

[0014] The experimental glass container washing and drying machine disclosed by the present invention includes an outer casing 1, a container placement cage 2, a blower 11, a heating element 12, and an exhaust fan 13. The bottom of the outer casing 1 is provided with a drain port 5, and the container is placed The cage 2 is arranged in the outer casing 1 and there is an air intake space between the outer casing 1. The container placement cage 2 is a flat rectangular parallelepiped structure, and one long side of the container placement cage 2 is an opening surface , the opening surface is hinged with the adjacent side wall and is provided with a locking mechanism for closing and locking, the other long side wall of the container placement cage 2 is provided with a container positioning column 3, and the container positioning column 3 It is a hollow structure and has a spray hole on the side wall. The inside of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com