Electric heating flow divider

A technology of electric heating and shunt, applied in the field of low pressure casting, can solve the problem of high cost, and achieve the effect of saving riser pipes, saving costs, improving safety and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

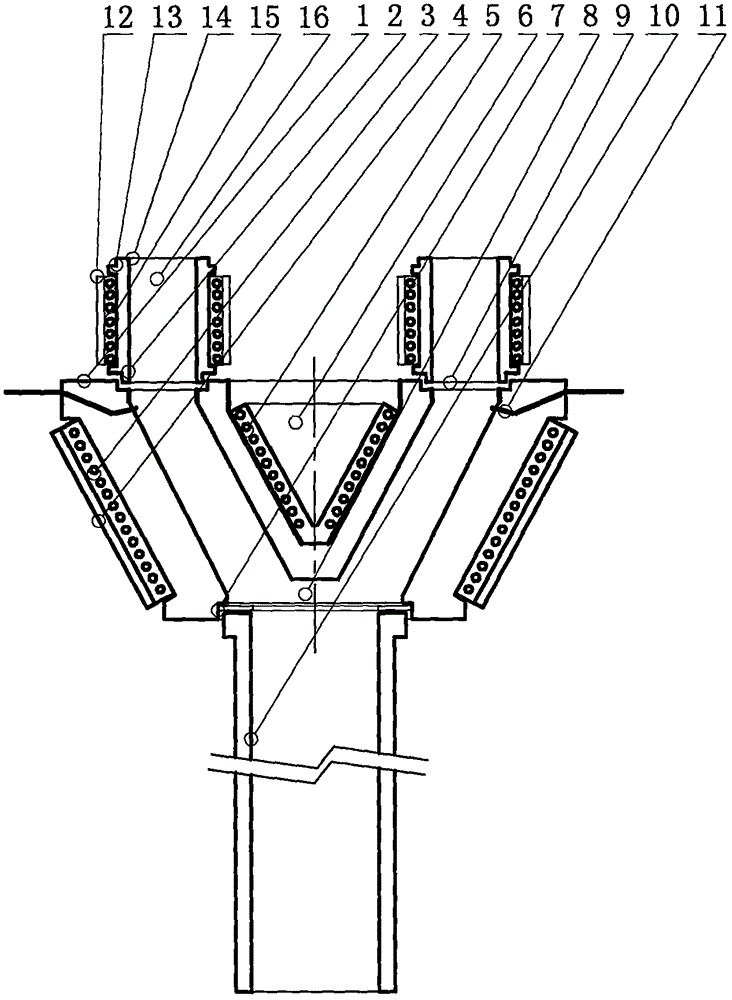

[0012] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 Including shunt body 1, shunt pipe groove 2, electric heating jacket 3, heat preservation jacket 4, electric heating core 5, vacuum insulation cone 6, riser pipe matching groove 7, main flow channel 8, shunt flow passage 9, riser pipe 10 , Liquid level contact 11, heat preservation ring 12, shunt pipe 13, shunt slot 14, spring heating ring 15, shunt hole 16, etc.

[0014] like figure 1 As shown, the application is an electric heating shunt, including a fluid diversion mechanism, a shunt cavity mechanism, and a heating and heat preservation mechanism;

[0015] The fluid-distributing mechanism includes a fluid-distributing body 1, a liquid riser matching groove 7, a distribution pipe groove 2, a thermal insulation ring 12, a shunt pipe 13, a shunt opening groove 14, a spring heating ring 15, and a shunt hole 16; The gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com