Pin puller based on memory alloy wire

A technology of memory alloy wire and pin puller, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of low current and power-on time requirements, difficult heating of memory alloy rods, and low power of memory alloy wires, etc., to achieve reliable Safety and security are easy to guarantee, the structure is simple, and the effect of large output pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

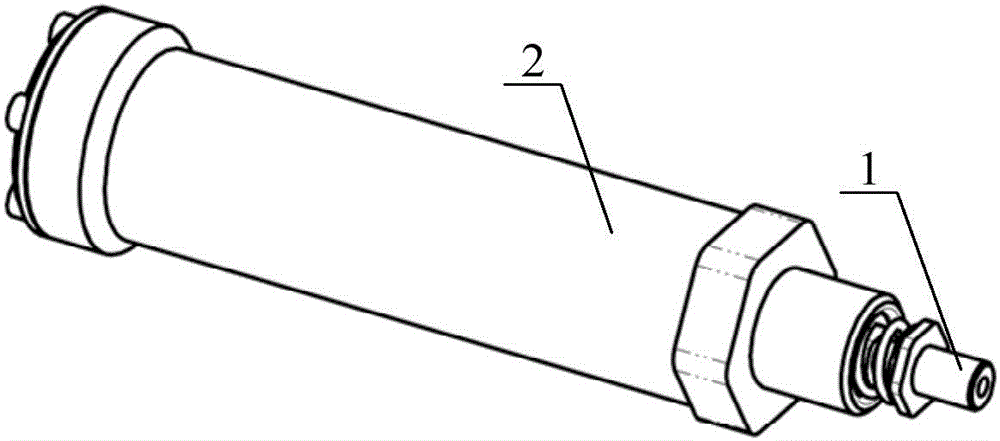

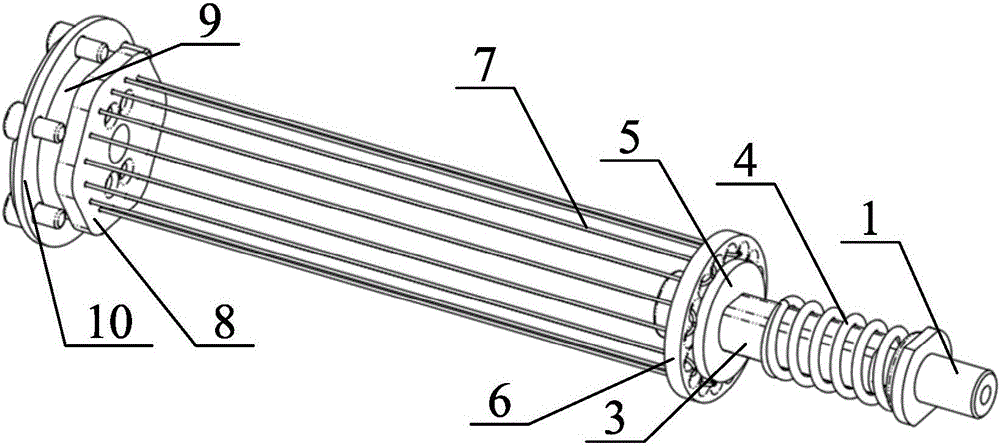

[0025] The present invention aims at the deficiency of prior art, proposes a kind of pin puller based on memory alloy wire, as figure 2 Shown is the overall outline schematic diagram of pin puller of the present invention, as image 3 Shown is a schematic diagram of the internal structure of the pin puller of the present invention, including a pin 1, a shell 2, a pull rod 3, a top spring 4, a front insulating pad 5, a pull plate 6, a memory alloy wire 7, a PCB board 8, and a rear insulating pad 9 , the rear cover 10, while the pin puller of the present invention also includes a power supply wire 11,

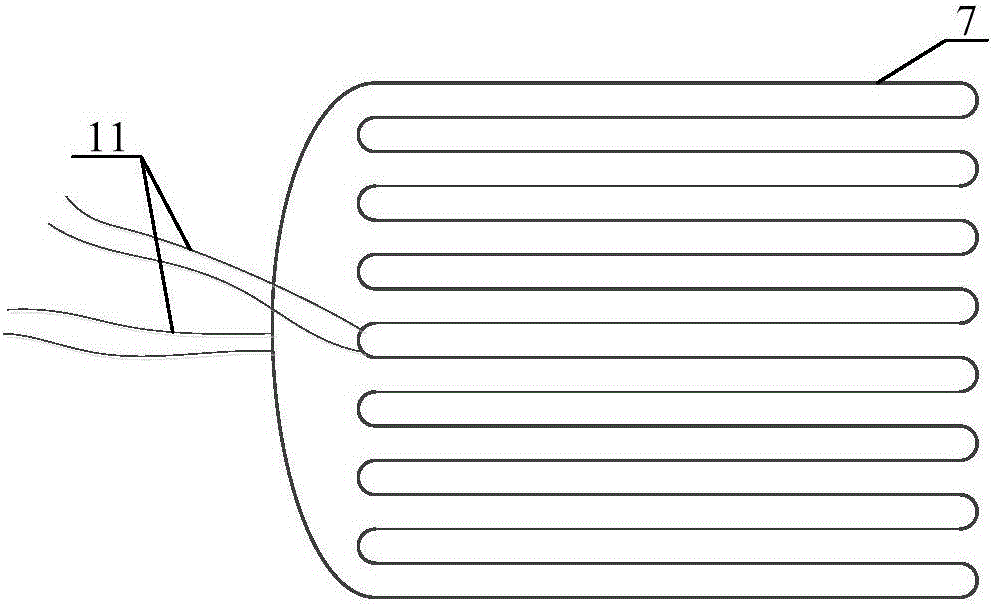

[0026] Such as figure 1 Shown is the electrical schematic diagram of the pin puller of the present invention. The memory alloy wires 7 are mechanically connected in parallel, first in series and then in parallel on the circuit. Therefore, mechanically, multiple memory alloy wires can be energized and contracted simultaneously to provide pulling force. The memory alloy wire on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com