Tire grabbing robot with triple speed

A technology of robots and tires, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of short stretching length, high cost, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

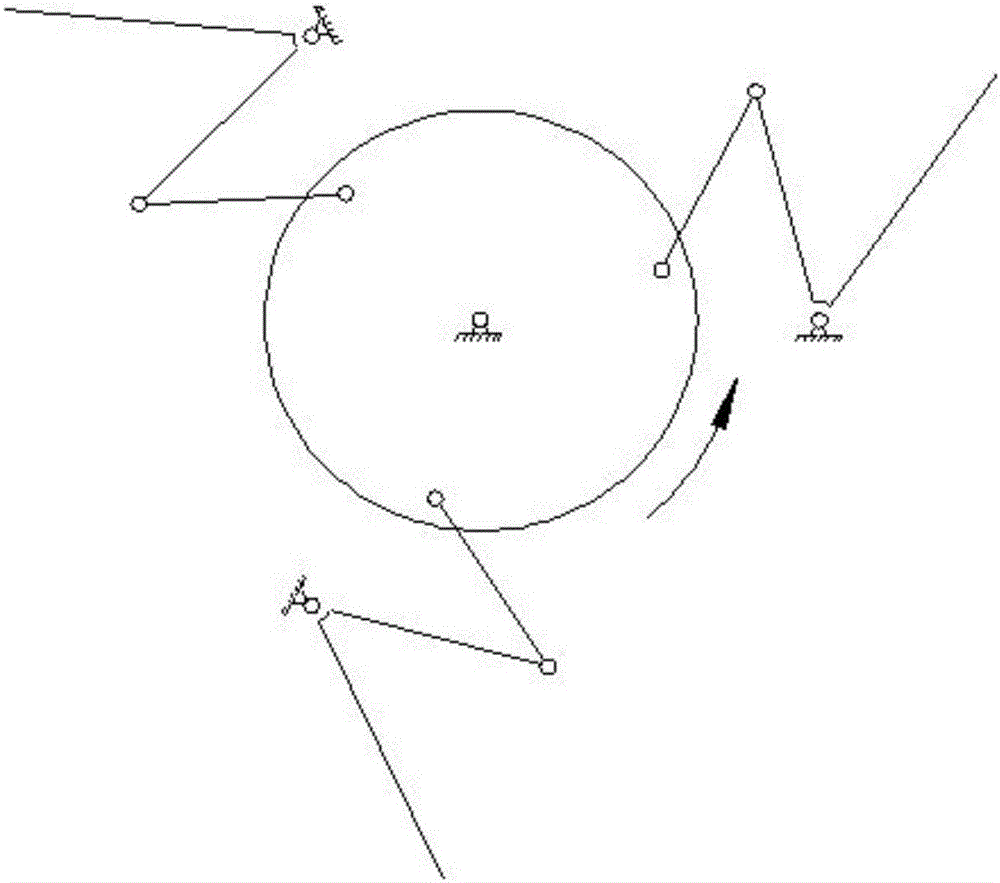

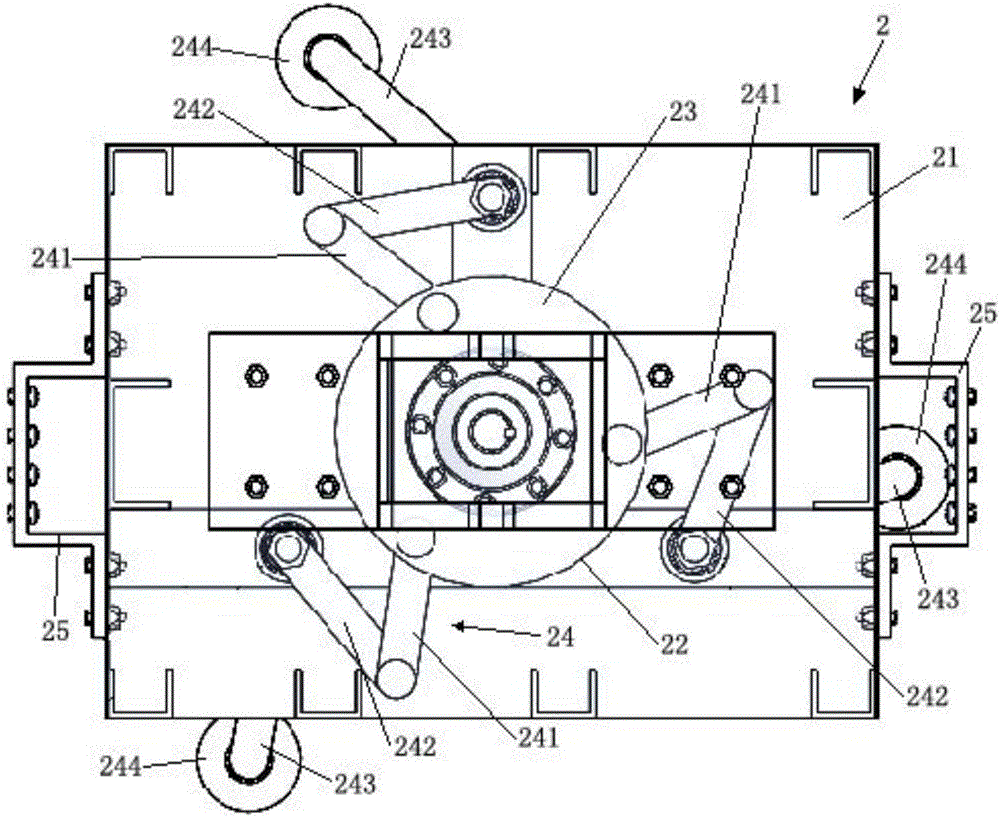

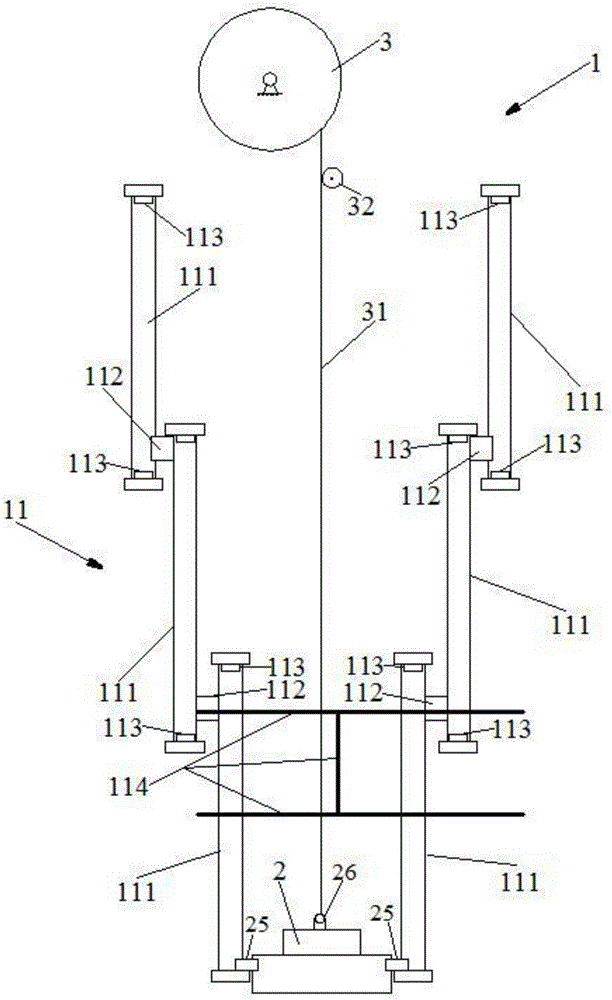

[0021] Below in conjunction with accompanying drawing, describe in detail the structural setting and operation principle of the present invention, detailed description is as follows:

[0022] The triple-speed tire grabbing robot includes a lifting part 1 and a grabbing part 2. The lifting part 1 includes two sets of symmetrically arranged guide rail chains 11. The guide rail chain 11 includes three linear guide rails 111. The grabbing part 2 is fixedly connected to the lifting part 1. On the lowermost linear guide rail 111 , the upper end of the lifting part 1 is also provided with a pulley 3 with a belt 31 , which is located between two groups of guide rail chains 11 .

[0023] The linear guide rail 111 is provided with sliders 112, wherein one section of the linear guide rail 111 is used as an intermediate body to connect the other two sections of the linear guide rail 111 to both ends of the head and the tail respectively through the slider 112, and the two ends of the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com