Book ATM and book catching manipulator with thickness measurement function

A technology for grasping manipulators and books, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as unreasonableness and waste of visible book storage space, and achieve the effect of accurately measuring the thickness of books and increasing the amount of visible books.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

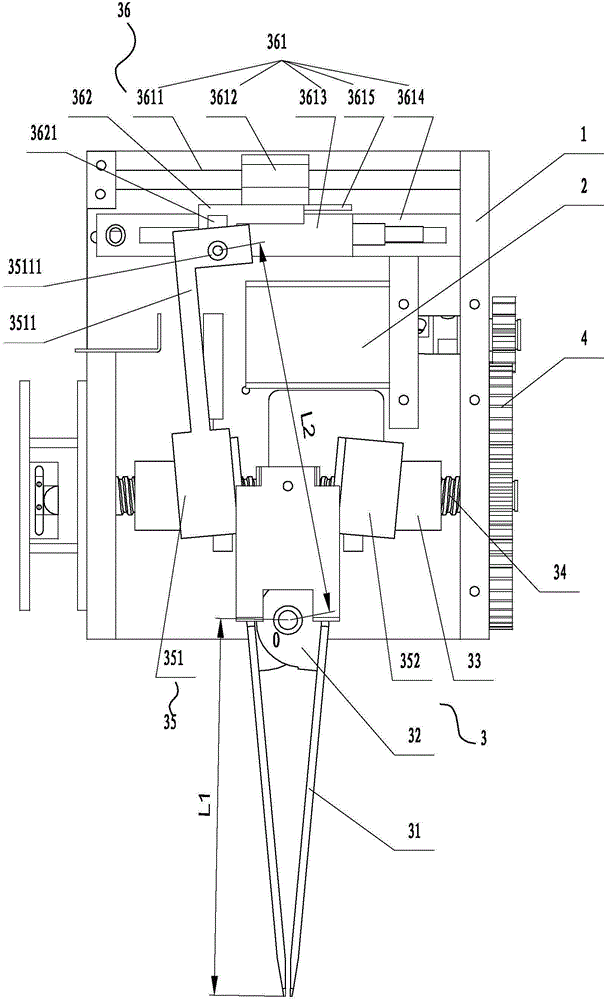

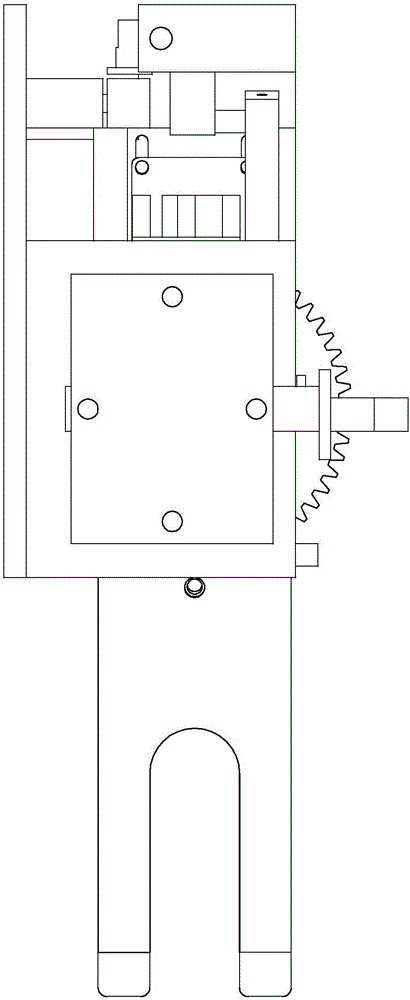

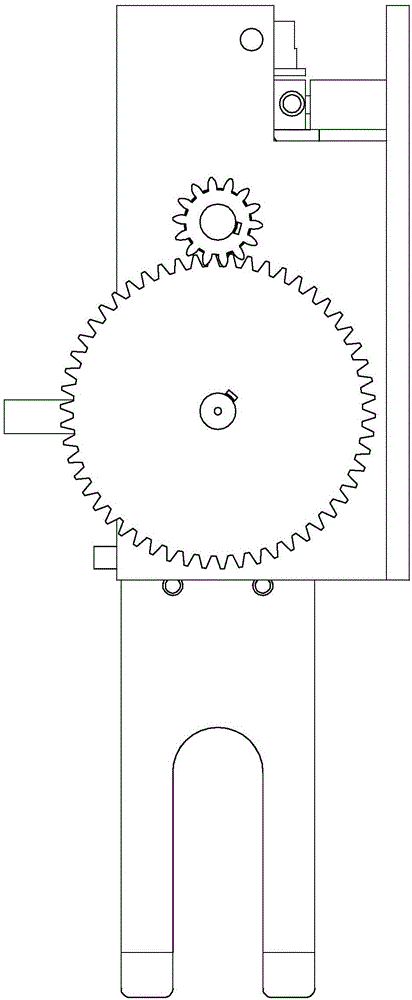

[0039] A book grabbing manipulator with thickness measuring function (see Figure 1-Figure 5 ), including a shell assembly 1, a motor 2, a screw splint assembly 3, and a transmission assembly 4. The screw splint assembly 3 includes two grasping manipulator splints 31, a rotating support block 32, a spring, a screw nut 33, a two-way Screw mandrel 34, screw mandrel nut stop block 35, the thickness measuring device 36 that is used to measure book thickness, wherein:

[0040] The screw nut limiting block 35 includes a screw nut limiting block A351 and a screw nut limiting block B352, the screw nut limiting block A351 is integrally formed with an L-shaped driving rod 3511, and the L-shaped driving rod 3511 is formed on the screw nut limiting block A351. The horizontal position is provided with a pin hole 35111; the thickness measuring device 36 includes a displacement sensor and its attached linear motion guide mechanism 361 and a groove shifting block 362, and the groove shifting ...

Embodiment 2

[0047] A book ATM machine, comprising a bookshelf 5, a book grabbing car, a vehicle frame, and a control system, the bookshelf 5 is provided with a book case 51, and a book grabbing manipulator is installed on the book grabbing car, and the width of the book case 51 is Uneven settings for different book thicknesses (see Figure 6 ); the width of the grid is set according to the specifications of 0~10mm, 11~20mm, 21~30mm, and 31~40mm respectively. The book grabbing manipulator is the book grabbing manipulator with thickness measuring function described in the first embodiment, and the output end of the displacement sensor of the book grabbing manipulator is connected to the input control end of the control system.

[0048] The above-mentioned book grabbing vehicle, vehicle frame, and control system are all prior art, and its structure will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com