Static liquid level control device and operating method thereof based on sla additive manufacturing technology

A technology of liquid level control and additive manufacturing, applied in the direction of manufacturing auxiliary devices, additive manufacturing, manufacturing tools, etc., can solve problems such as disturbance, stress and deformation, and achieve the effect of liquid level maintenance, small quantity, and stable liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

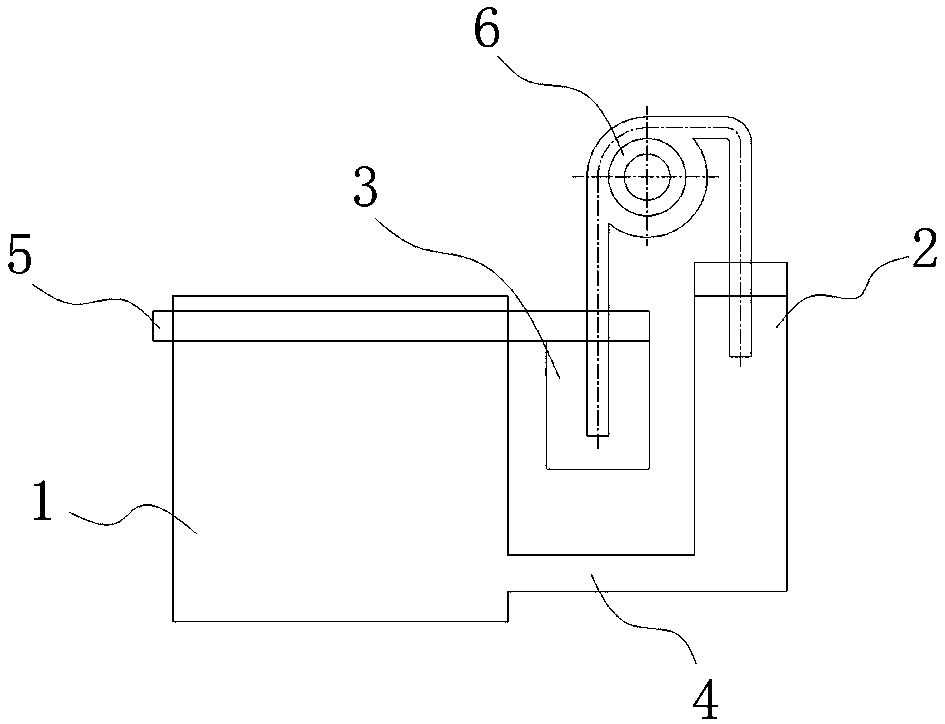

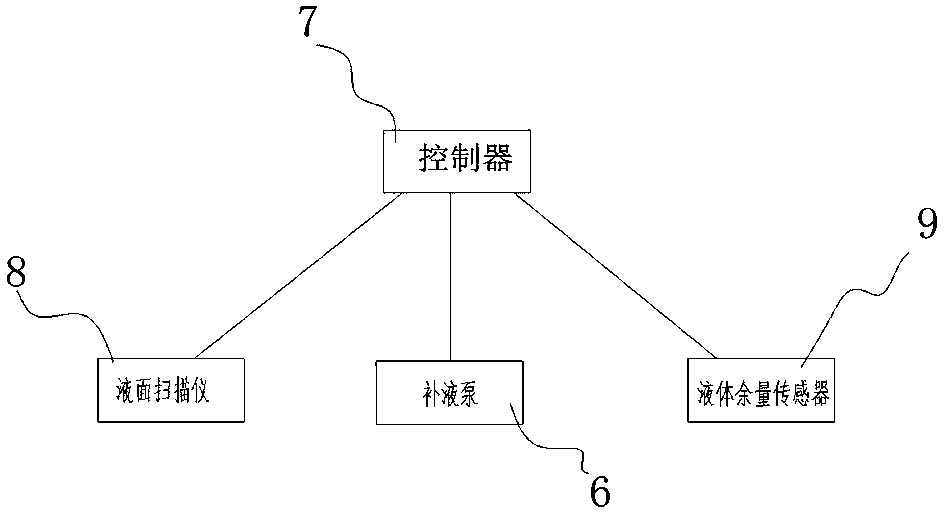

[0024] Embodiment 1: as figure 1 and figure 2 As shown, a static liquid level control device based on SLA additive manufacturing technology includes a liquid replenishment component and a control component, and the control component controls the liquid replenishment component;

[0025] The liquid replenishment assembly includes a main liquid tank 1, a secondary liquid tank 2, and a liquid replenishment tank 3. The bottom of the main liquid tank 1 communicates with the bottom of the liquid replenishment tank 3 through a communication pipe 4. The height of the liquid replenishment tank 3 is Greater than or equal to the height of the main liquid tank 1, the outer wall of the main liquid tank 1 is provided with an overflow backflow notch 5, and the overflow backflow notch 5 communicates with the secondary liquid tank 2, and the secondary liquid A liquid replenishment pump 6 is provided between the tank 2 and the liquid replenishment tank 3;

[0026] The control assembly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com