Method and system for controlling temperature and humidity in moisture regain zone of tobacco sheet redrying machine

A temperature and humidity control and humidity control technology, which is applied in the fields of tobacco, tobacco preparation, and application, can solve the problems of large fluctuation of tobacco leaf quality and mutual interference of multiple parameters, and achieves small moisture fluctuation range, small control range and good control effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

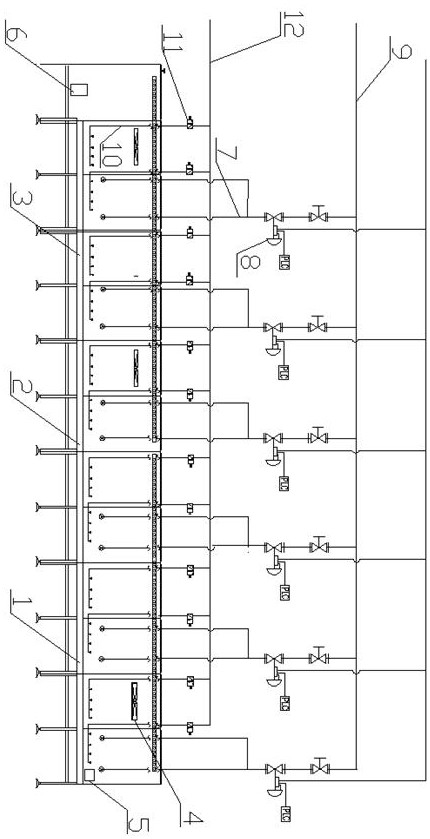

[0021] The method for controlling the temperature and humidity in the re-moisture zone of the tobacco sheet re-drying machine is characterized in that the method comprises the following steps:

[0022] a. Divide the resurgence area into three areas from the inlet to the outlet, namely the first area of resurgence, the second area of resurgence and the third area of resurgence, and set the system setting values of each area according to experience;

[0023] b. Obtain the deviation and deviation change rate: the system set value x, the sensor obtains the indoor data collection value y, x and y are sent to the controller PLC, and the deviation e is obtained by comparing the two, and the deviation e is calculated with time as a variable Guide to obtain the deviation change rate ec;

[0024] c. Obtain the limit value of the deviation change rate ec, and adopt fuzzy PID control method partition control: obtain the upper limit value |ec1| of the minimum interval of the error ...

Embodiment 2

[0028] In order to further improve the technical solution in embodiment 1, the system setting value described in this embodiment is the temperature setting value of each district, and the collection value is the temperature collection value of each district; the opening adjustment amount of the pneumatic membrane valve in step d The calculation formula is as follows: ,in: is the proportional gain; is the integral time constant; is the differential time constant; It is the deviation between the collected value and the set value. Resurgence three-zone control corresponds to the (0, |ec1|) range 1 of the ec value. At this time, it is necessary to reduce the overshoot to reduce the system steady-state error, and appropriately introduce differential or integral functions; the resurgence two-zone control corresponds to the ec value. (|ec1|, |ec2|) Range 2, at this time, the system output tends to the desired value, and a smaller proportional coefficient and a larger integr...

Embodiment 3

[0030] In order to further improve the technical solution in embodiment 1, the system setting value described in this embodiment is the moisture content of the tobacco leaf set, and the collection value is the moisture content of the tobacco leaf detected by the moisture meter at the outlet; the nozzle that needs to be opened in step d quantity The calculation formula is as follows: , where: L is the flow rate of the smoke sheet, that is, the weight of the smoke sheet entering the moisture resurgence zone per unit time; is the tobacco leaf moisture content detected by the moisture meter at the entrance; is the tobacco leaf moisture content detected by the moisture meter at the outlet; is the moisture content of tobacco leaves set; is the influence value of steam on the moisture content of tobacco leaves; is the effective utilization rate of atomized water; is the atomization amount of the nozzle, that is, the amount of water sprayed by the nozzle per unit time. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com