Square iron pipe flattening device for hardware machining

A technology of iron and square tubes, which is applied to presses, manufacturing tools, etc., can solve the problems of large space occupied by square tubes and waste of plant resources, and achieve the effects of reducing occupied space, improving safety, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

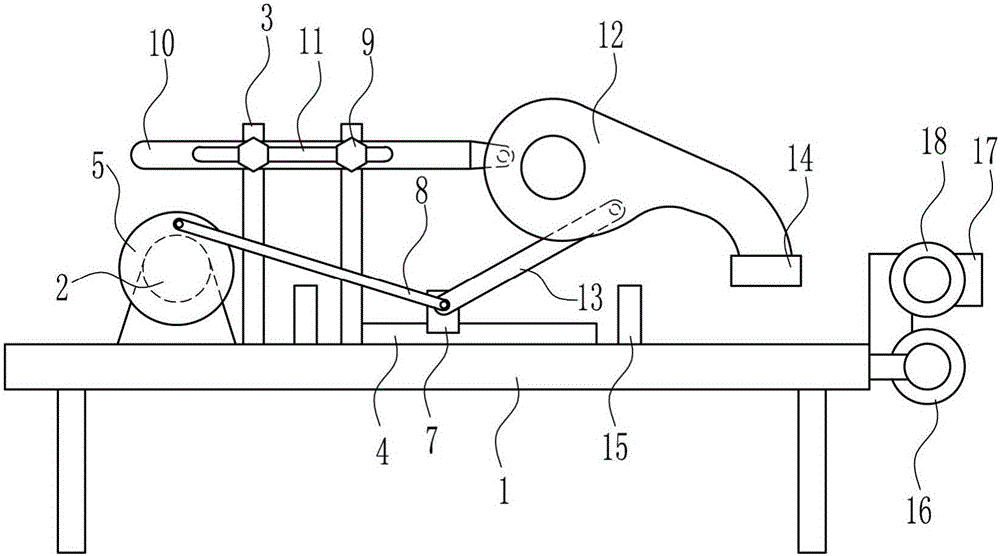

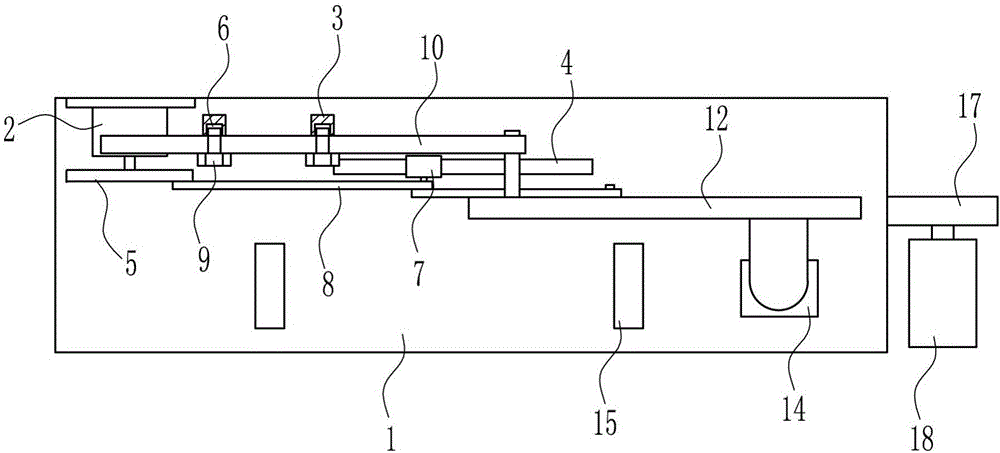

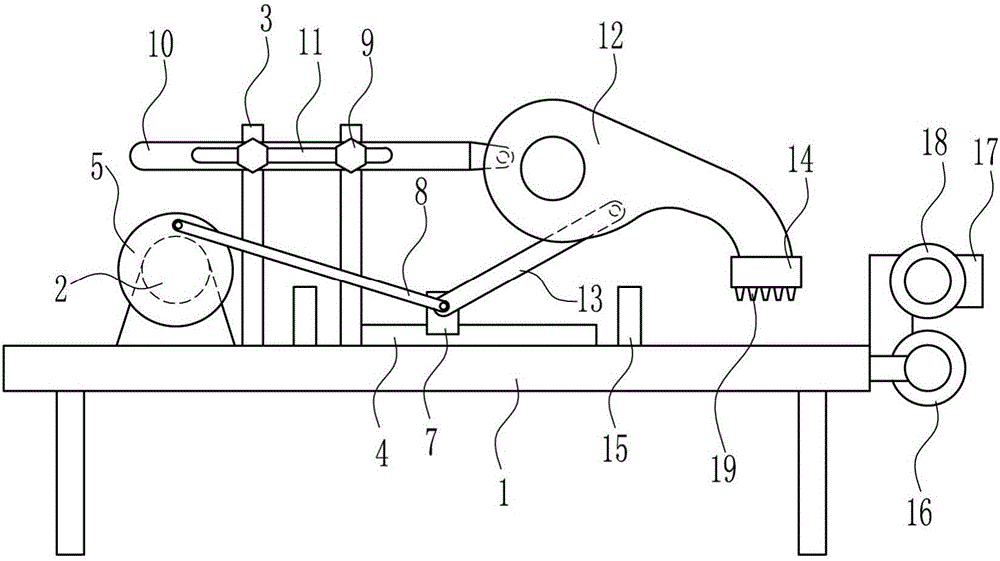

[0031] An iron square tube flattening device for metal processing, such as Figure 1-6 As shown, it includes a workbench 1, a motor 2, a pole 3, a slide rail 4, a disk 5, a slider 7, a first connecting rod 8, a bolt 9, an adjusting rod 10, a swing block 12, a second connecting rod 13, Pressure head 14, guide sleeve 15, electric lower pressure wheel 16, fixed plate 17 and electric upper pressure wheel 18, the rear part of workbench 1 is provided with motor 2, pole 3 and slide rail 4 in sequence from left to right, motor 2 A disc 5 is connected to the output shaft of the motor 2, and the disc 5 is located on the front side of the motor 2. There is a threaded hole 6 on the front side of the upper part of the pole 3, and a sliding block 7 is provided on the slide rail 4, and the front side of the slider 7 is The side is concentrically connected with a first connecting rod 8 and a second connecting rod 13, the other end of the first connecting rod 8 is hingedly connected with the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap