High efficiency press

A press, high-efficiency technology, applied in the field of presses, can solve the problems of wasting resources, straw cannot be returned to the field, etc., and achieve the effect of fast operation, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

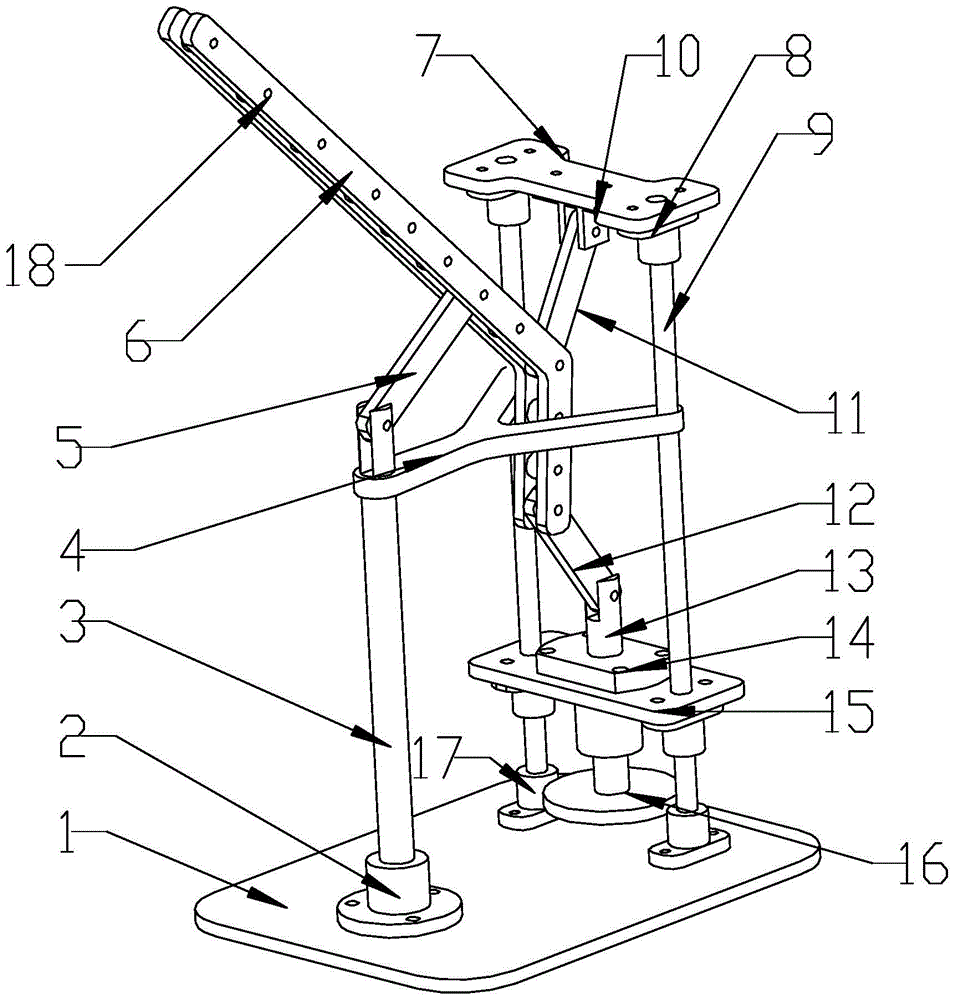

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0011] Example. High-efficiency press, constituted as figure 1 As shown, it includes a base 1, the base 1 is provided with a pressure support rod fixing seat 2 and a pressure plate support frame, the pressure support rod fixing seat 2 is provided with a pressure support rod 3, and the middle part of the pressure support rod 3 is provided with a supporting pressure plate support frame The Y-shaped connecting frame 4, the upper end of the pressure support rod 3 is hinged with a short pressure rod 5, the end of the short pressure rod 5 is hinged with an L-shaped long pressure rod 6, and the short side ends of the L-shaped long pressure rod 6 are sequentially hinged with a tension connection Rod 12, platen connecting rod 13, the lower end of the platen connecting rod 13 is provided with a platen 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap