Environment-friendly type plastic bottle treatment device

A treatment device and sewage treatment device technology, applied in plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of large space occupation, heavy workload, high labor intensity, etc., to improve work efficiency, save steps, and facilitate The effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

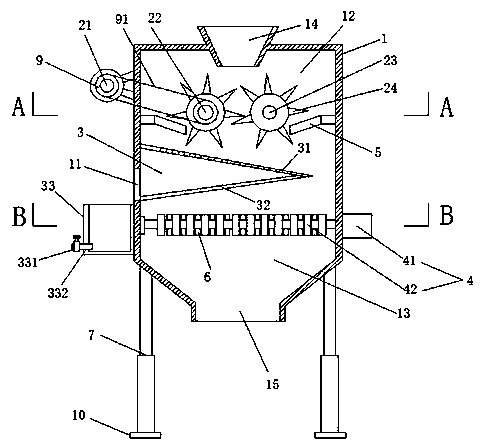

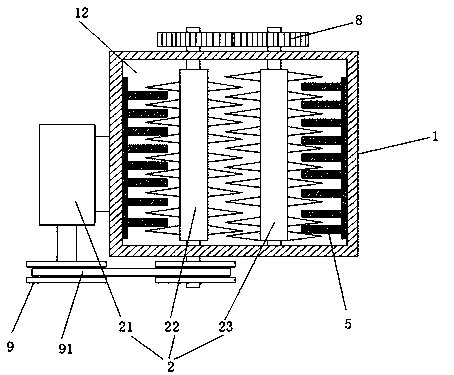

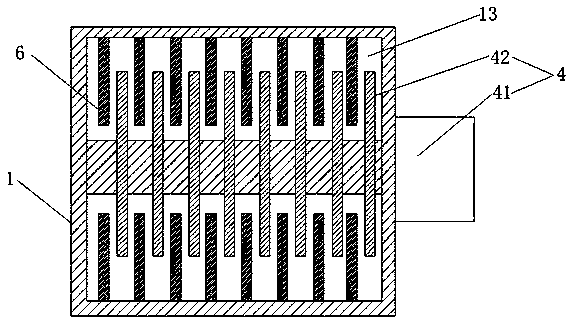

[0026] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown device for treating plastic bottles for environmental protection includes a shell 1, a hole punching device 2, a sewage treatment device 3 and a crushing device 4. A sewage outlet 11 is opened on the side of the shell 1, and the sewage treatment device 3 Including a water leakage plate 31, a drainage plate 32 and a water receiving box 33, the water leakage plate 31 and the drainage plate 32 are fixedly arranged in the interior of the casing 1 in an isosceles triangle, and the water receiving box 33 is welde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap