A quantitative paper tube code tube binding device

A strapping device and paper tube technology, which is applied in the direction of strapping materials, strapping machine parts, packaging, etc., can solve problems such as low operating efficiency, paper tubes that cannot be squeezed, and error-prone, and achieve high work efficiency and fast coding. Tube bundling, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

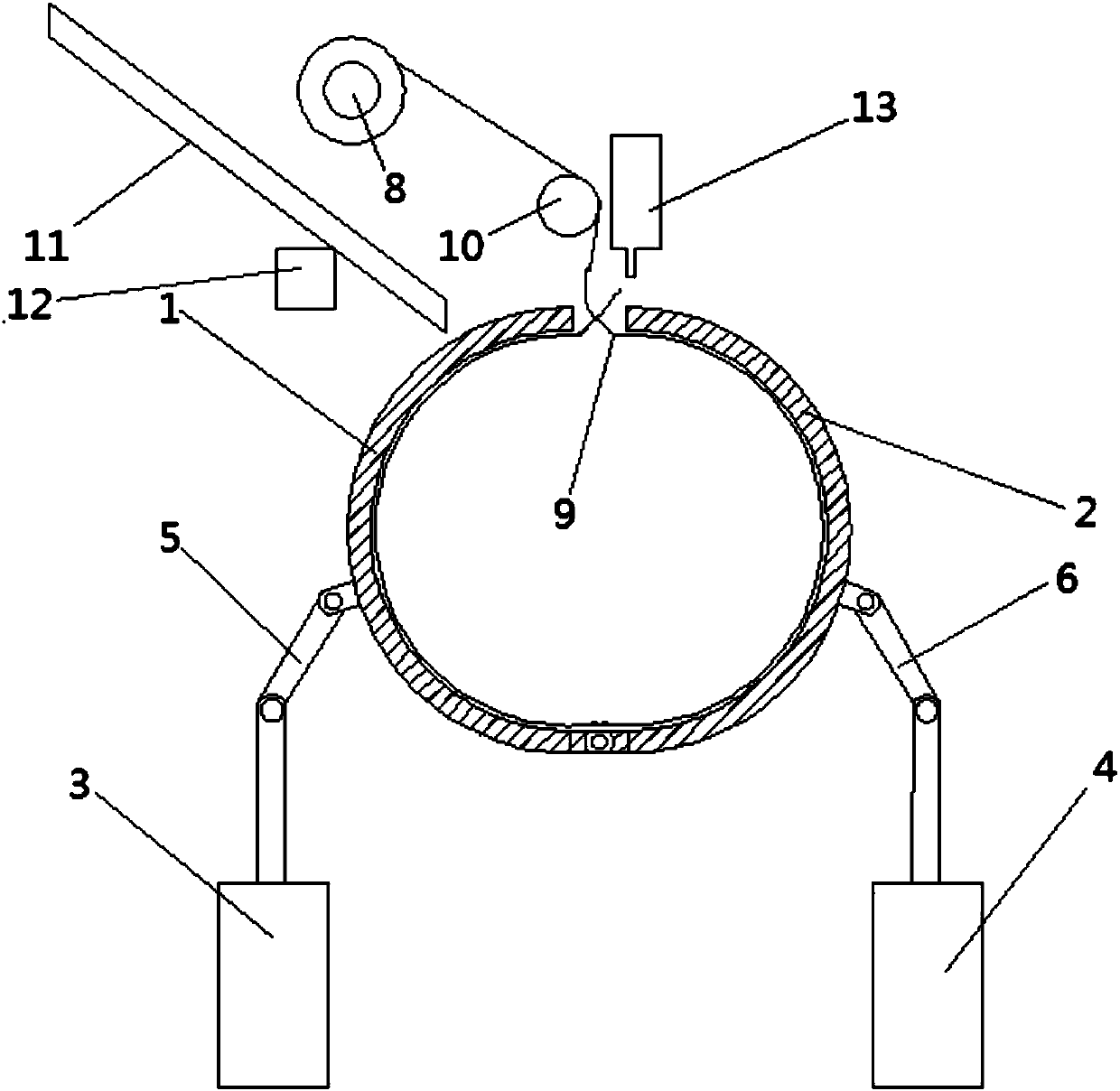

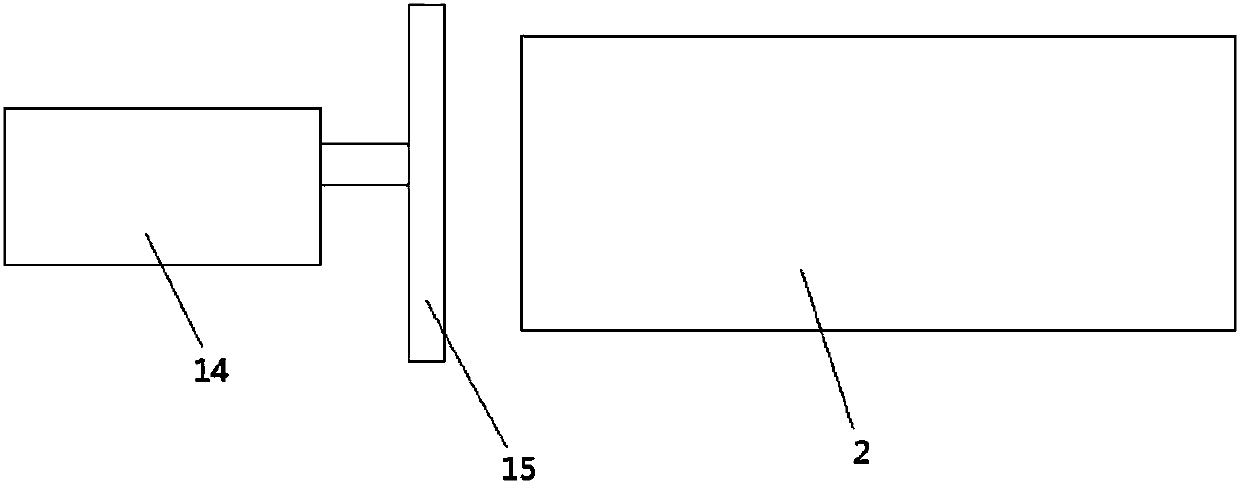

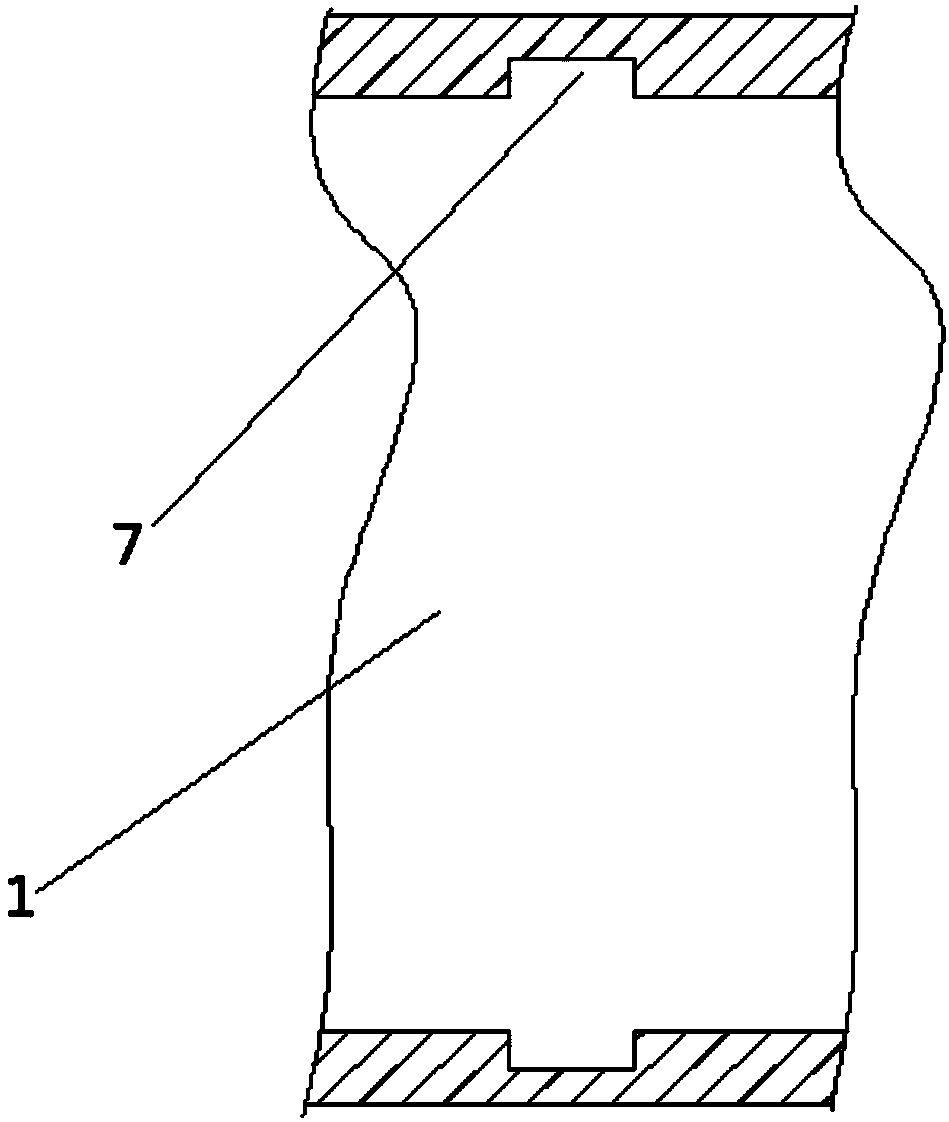

[0020] see Figure 1-4 : A quantitative paper tube code tube binding device includes a structural part and a control part, and the structural part includes arc seats 1 and 2 arranged on left and right sides, and the bottom ends of the two arc seats 1 and 2 Hingedly connected, cylinders 3, 4 are respectively arranged on the outsides of the two arc seats 1, 2, and the piston rods of the cylinders 3, 4 are hingedly connected with pull rods 5, 6, and the two pull rods 5, 6 are connected with the arc seats 1 on both sides respectively. , 2 are hingedly connected; the inner walls of the two arc-shaped seats 1 and 2 are respectively provided with arc-shaped draw-in slots 7, and a motor 8 is arranged above the two arc-shaped seats 1 and 2, and the motor shaft of the motor 8 is wound There is a rope 9, and a fixed pulley 10 is also provided on one side of the motor 8. The rope 9 is pulled around the fixed pulley 10, and then pulled from the arc-shaped slot 7 of the right-side arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com