A quantitative paper tube cutting yard tube binding device

A binding device and paper tube technology, which is applied in the direction of binding objects, binding materials, packaging/binding items, etc., can solve problems such as error-prone, paper tubes cannot be squeezed, and low operating efficiency, achieving fast cutting and high work efficiency , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

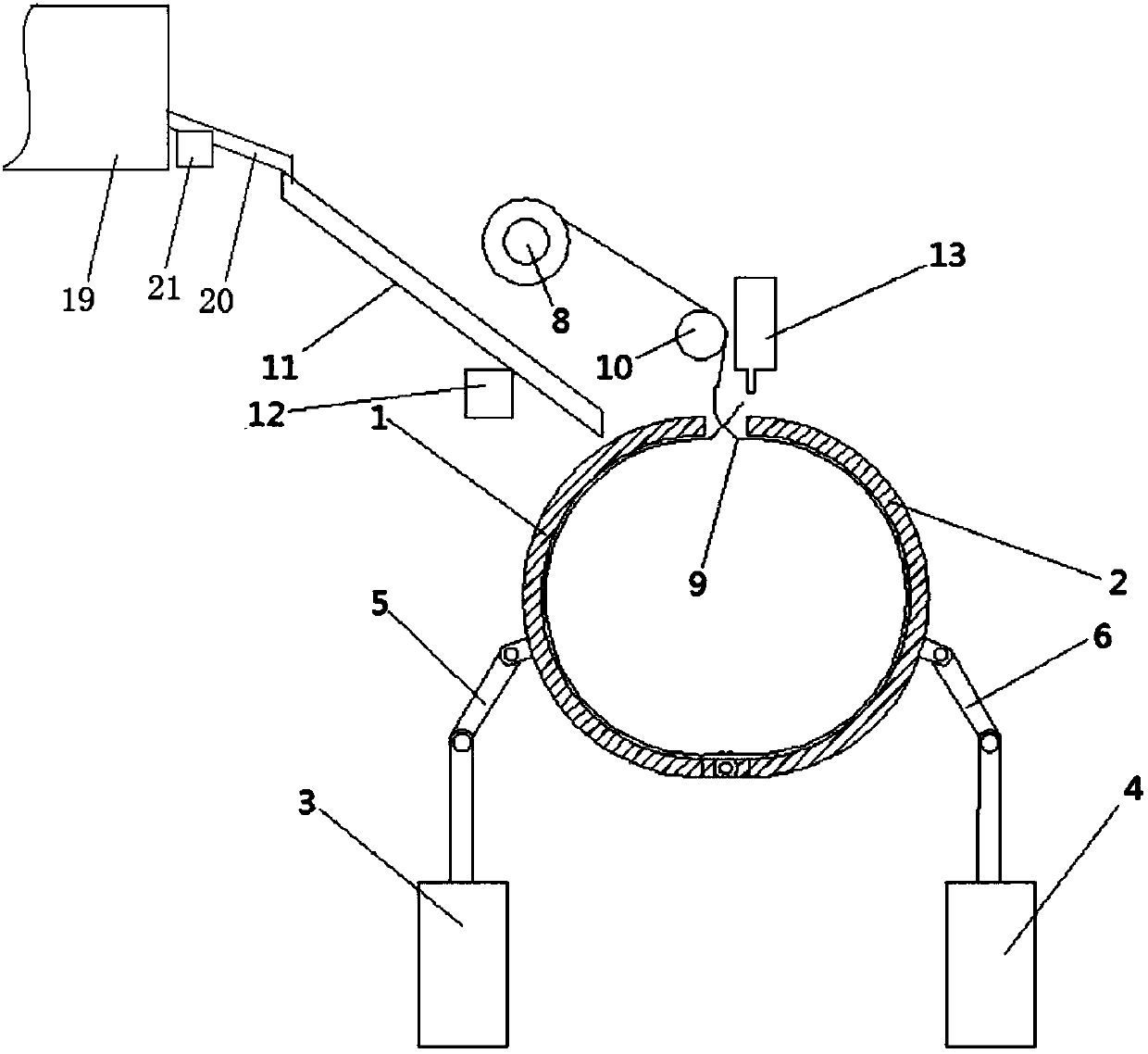

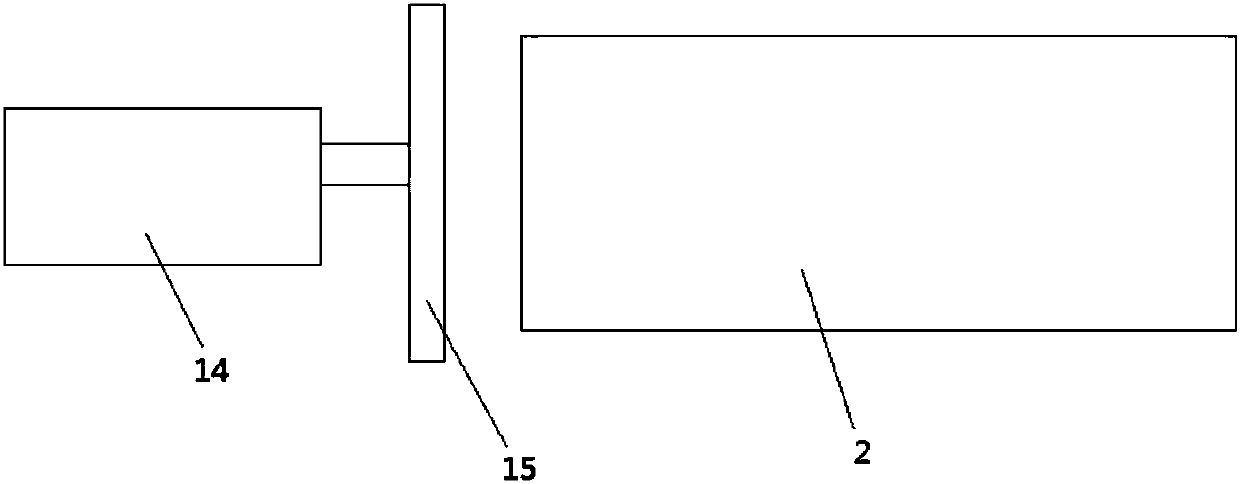

[0020] See Figure 1-4 : A quantitative paper tube cutting and tying tube bundling device, including a structural part and a control part. The structural part includes a cutting part and a yard tube bundling part. The cutting part includes a paper tube cutting machine 19 and the discharge of the paper tube cutting machine 19 A downwardly inclined discharge plate 20 is provided at the mouth, and a counting device 21 is provided on the upper side of the discharge plate 20;

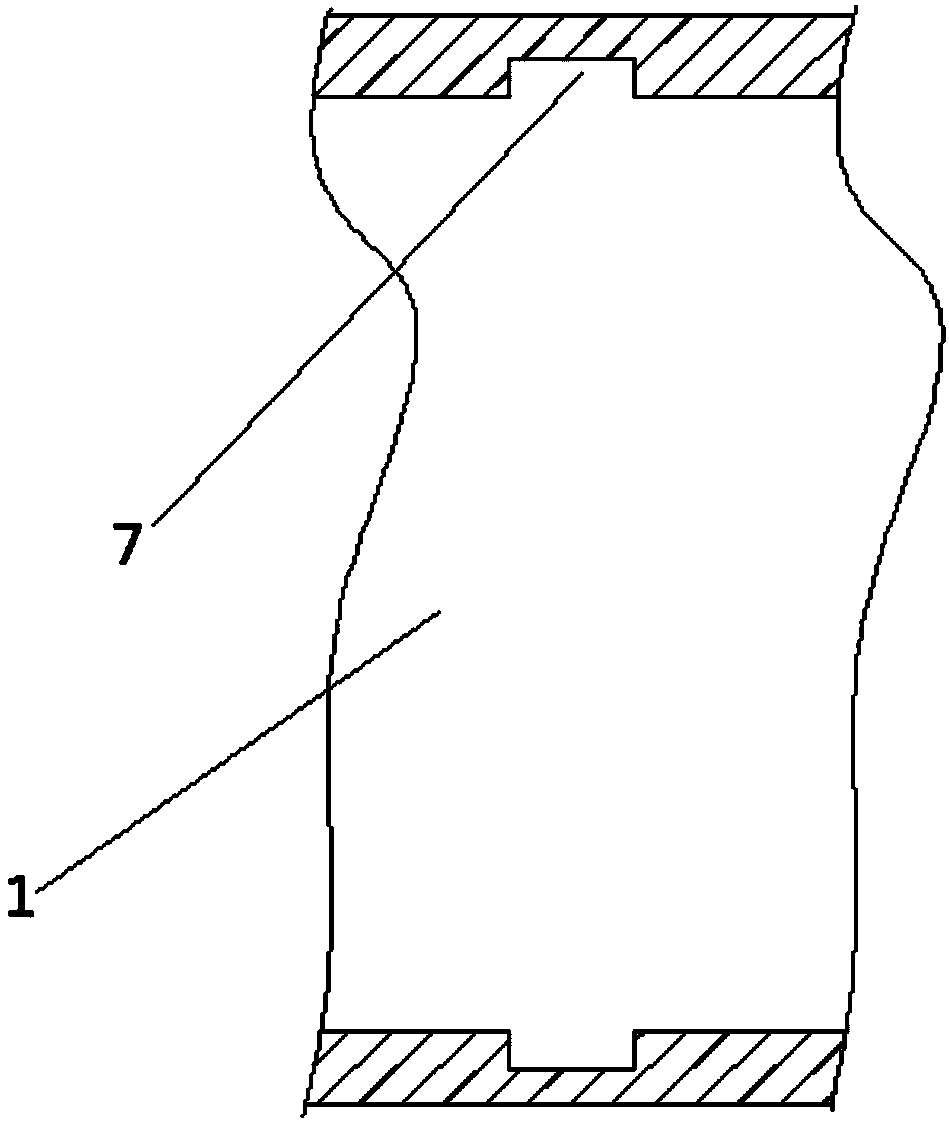

[0021] The tube bundling part includes arc-shaped seats 1, 2 arranged on the left and right sides. The bottom ends of the two arc-shaped seats 1, 2 are hingedly connected, and cylinders 3, 2 are provided on the outer sides of the two arc-shaped seats 1, 2 respectively. 4. The piston rods of the cylinders 3 and 4 are hingedly connected with tie rods 5 and 6, and the two tie rods 5 and 6 are hingedly connected to the arc seats 1 and 2 on both sides; the inner walls of the two arc seats 1 and 2 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com