Material grabbing and strapping mechanism of bag management machine

A strapping mechanism and strapping machine technology, applied in the direction of strapping materials, packaging, etc., can solve the problems of irregular packaging bags, high cost, and impact on the strapping process, and achieve the effect of reducing labor costs, high degree of automation, and good strapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

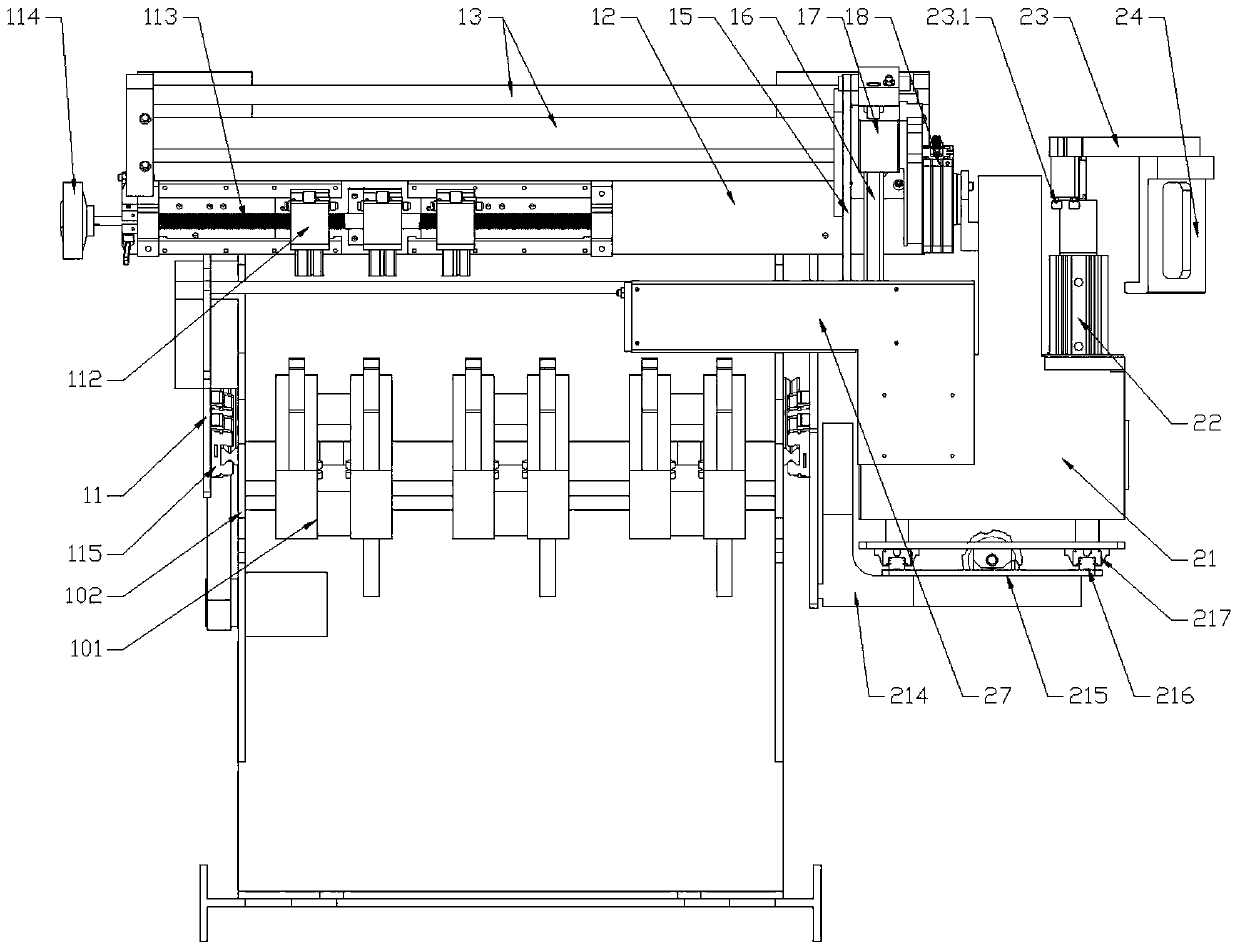

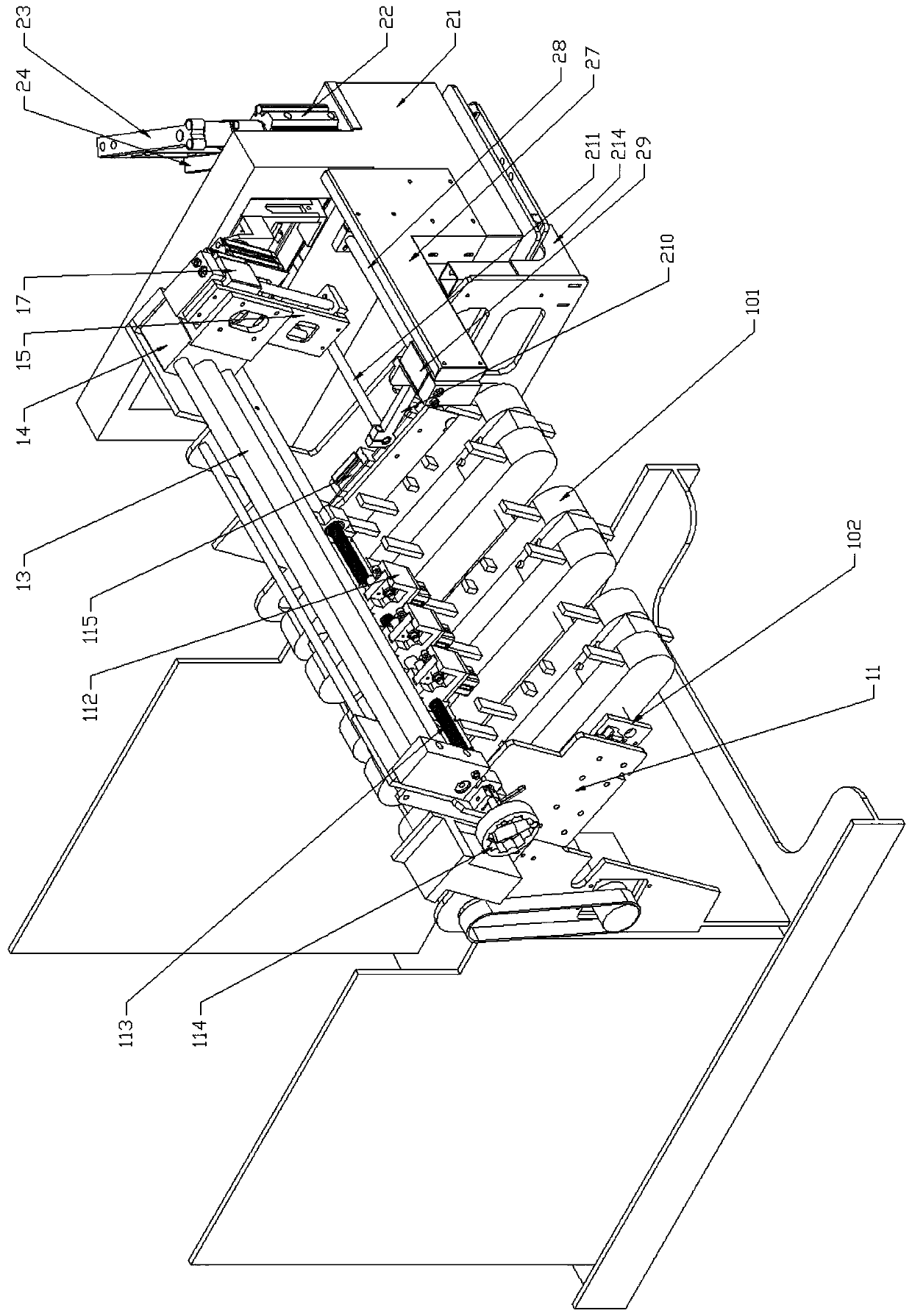

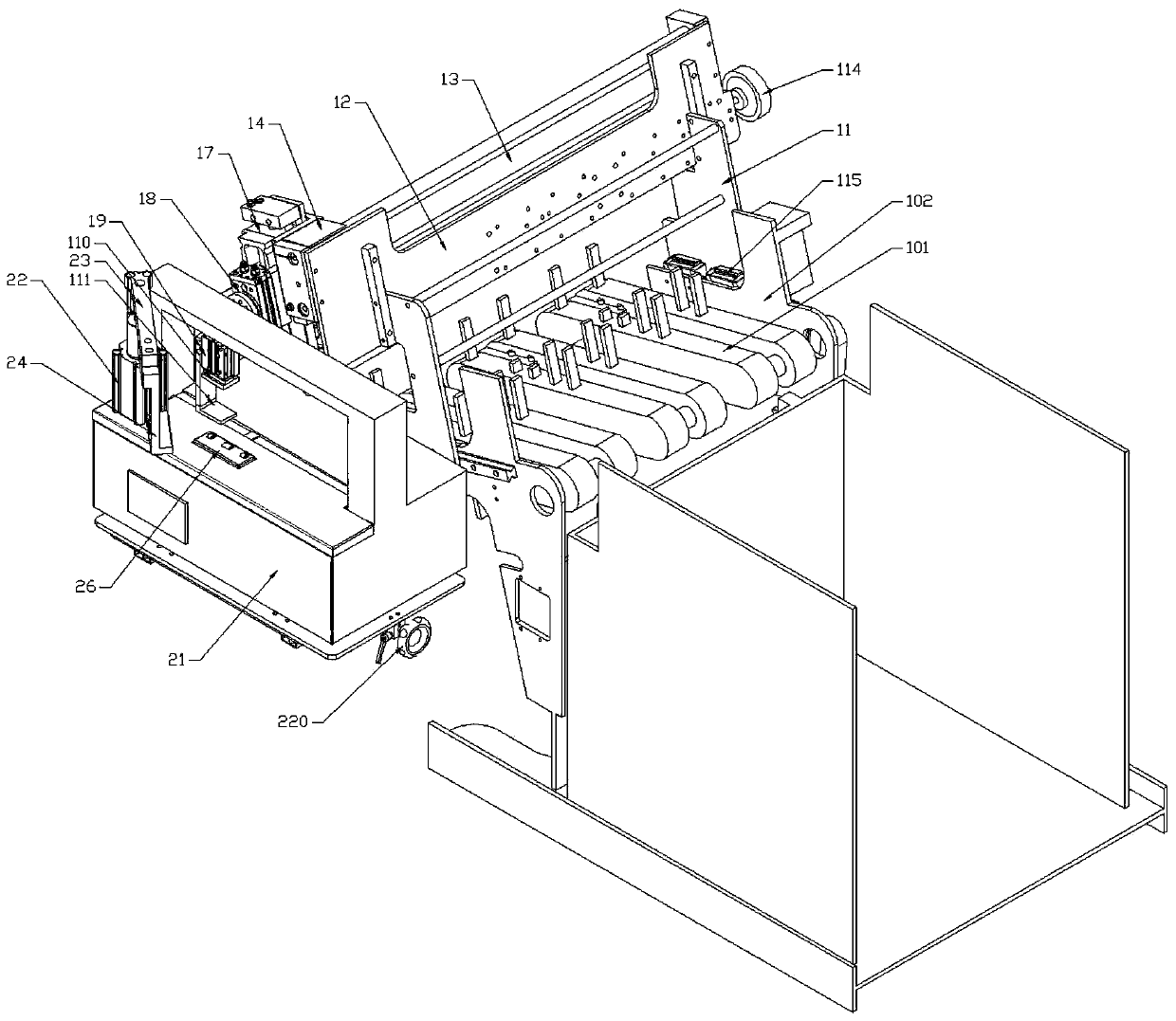

[0039] Embodiment one: if figure 1 - As shown in 6, a grabbing and binding mechanism of a bag unscrambling machine, including a grabbing mechanism and a binding mechanism, is installed at the rear of the bag unscrambling machine. The structure at the rear of the bag unscrambling machine includes several finishing assemblies 101 and two For the finishing wallboard 102 , the material-grabbing mechanism includes a material-grabbing wallboard 11 installed outside the finishing wallboard 102 , and the material-grabbing wallboard 11 and the finishing wallboard 102 are connected by a slider guide rail assembly 115 . A translation installation plate 12 is arranged between the grasping wallboards 11, and a plurality of translation guide shafts 13 are arranged on the translation installation plate 12. A translation cylinder 14 is provided on the translation guide shaft 13, and a lifting installation plate 15 is provided on the translation cylinder 14. Mounting plate 15 is provided with ...

Embodiment 2

[0041] Embodiment two: combine Figure 4-8 As shown, on the basis of Embodiment 1, a limit assembly is added to the grabbing mechanism to limit the movement of the translation cylinder 14 when grabbing materials. The translation mounting plate 12 is provided with a screw rod 113 and a stopper 112. The outer end of screw mandrel 113 is provided with handwheel 114, and limiter 112 includes limit mounting seat 112.1 and limit cylinder 112.2, and the cylinder movable rod 112.3 of limit cylinder 112.2 is connected limit slide block 112.4, and set limit slide block 112.4 The limit sensor 112.5, the limit mounting seat 112.1 is provided with the slider groove 112.1.1 for accommodating the limit slider 112.4 and the hole 112.1.2 for the screw rod 113 to pass through, and the limit mounting seat 112.1 rear portion is provided with a guide block 112.1.3. Wherein, the middle of the screw rod 113 is the optical axis, the number of stoppers 112 is three, the middle stopper 112 is located ...

Embodiment 3

[0042] Example Three: Combining Figure 9-13 As shown, on the basis of Embodiment 1 or Embodiment 2, a pusher assembly and an upper support assembly are added to the strapping mechanism. The pusher assembly is located inside the strapping machine 21 and includes a pusher mounting plate 27 connected to the strapping machine 21. Pushing material installation plate 27 is provided with some horizontal pushing material guide shafts 28, and pushing material translational cylinder 29 is provided on pushing material guiding shaft 28, and pushing material translational cylinder 29 is provided with rotating mounting plate 213, and rotating mounting plate 213 is provided with There is a material pushing rotary cylinder 212, which is connected to one end of the rocking arm 210, and the other end of the rocking arm 210 is provided with a push rod 211.

[0043] combine Figure 10-17 As shown, the upper support assembly is located outside the strap groove 21.1, and includes the upper suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com