Building steel bar bending equipment

A construction steel bar and bending technology, applied in metal processing equipment, packaging, transportation and packaging, etc., can solve problems such as low production efficiency, high labor intensity of workers, and heavy steel bar weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

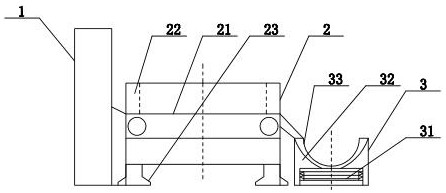

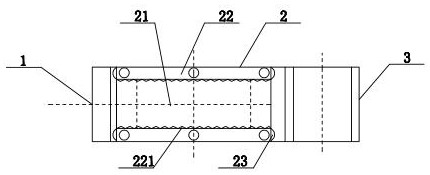

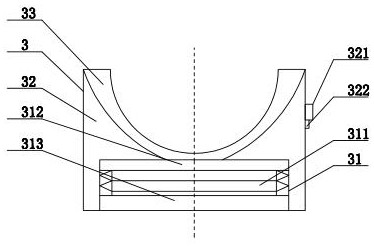

[0017] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: a kind of building steel bar bending equipment, which includes a cutting device 1, a conveying device 2, and a collecting device 3; the conveying device 2 is arranged on the right side of the cutting device 1, and collects The device 3 is arranged below the conveying device 2, and the conveying device 2 includes a first conveying belt 21, a second conveying belt 22, and a fixed seat 23; the number of the second conveying belts 22 is two, and the two second conveying belts 22 Respectively vertically arranged at both ends of the first conveyor belt 21, the number of the fixed seats 23 is four, and the four fixed seats 23 are respectively arranged on the periphery of the first conveyor belt 21, and the collection device 3 includes a shock absorber 31. A weighing device 32 , a storage box 33 ; the weighing device 32 is arranged above the shock absorbing device 31 , and the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com