Stable and controllable powder conveying device and method

A conveying device and powder technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of affecting the production process, economic loss, and reducing production efficiency, so as to reduce the impact, ensure accuracy, and improve conveying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

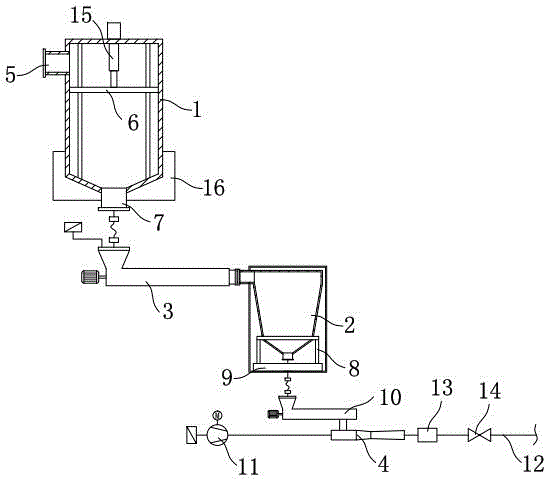

[0014] The powder stable and controllable conveying device and method of the present invention will be further described below in conjunction with the accompanying drawings:

[0015] The stable and controllable powder conveying device of the present invention is composed of a front powder box 1 , a powder measuring box 2 , a screw conveyor 3 and a Venturi tube 4 .

[0016] Wherein, the sidewall of front powder box 1 is provided with powder inlet 5, and the bottom of this front powder box 1 is provided with powder outlet 7, and the top of front powder box 1 is provided with electric push rod 15, and the top of this electric push rod 15 One end is fixed to the top of the front powder box 1, and the other end is vertically fixed above the powder pressing plate 6 in the front powder box 1. The powder pressing plate 6 should be relatively sealed to the inner wall of the front powder box 1 to prevent redundant The powder material leaks to the top of the powder compactor 6, causing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com