Waste and solid waste gasifier

A solid waste and gasifier technology, which is applied in gasification process, granular/powder fuel gasification, manufacture of combustible gas, etc., can solve problems such as short service life, and achieve the effect of good continuity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

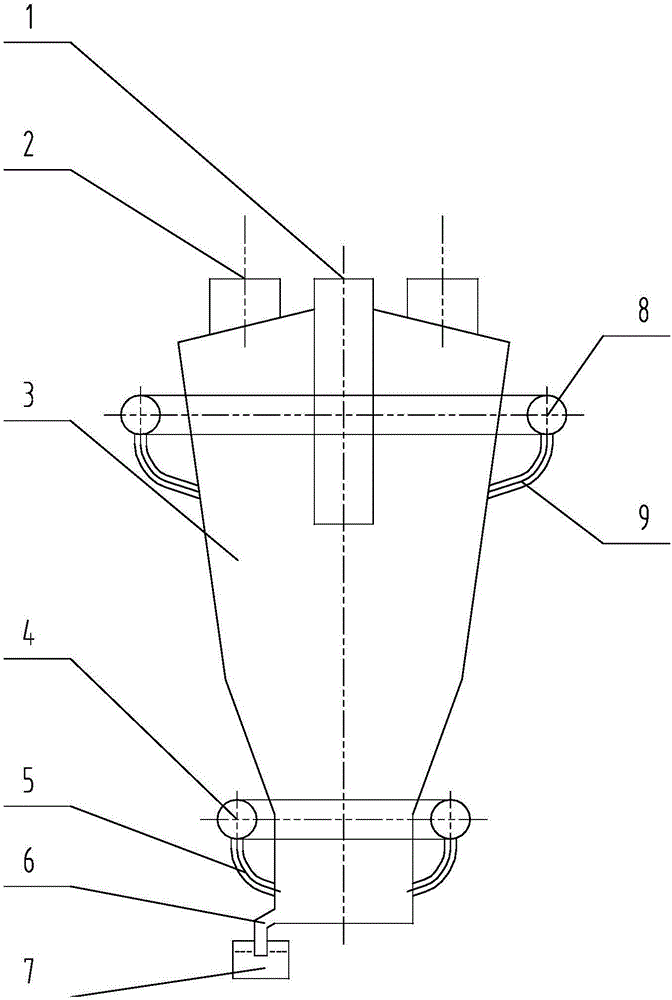

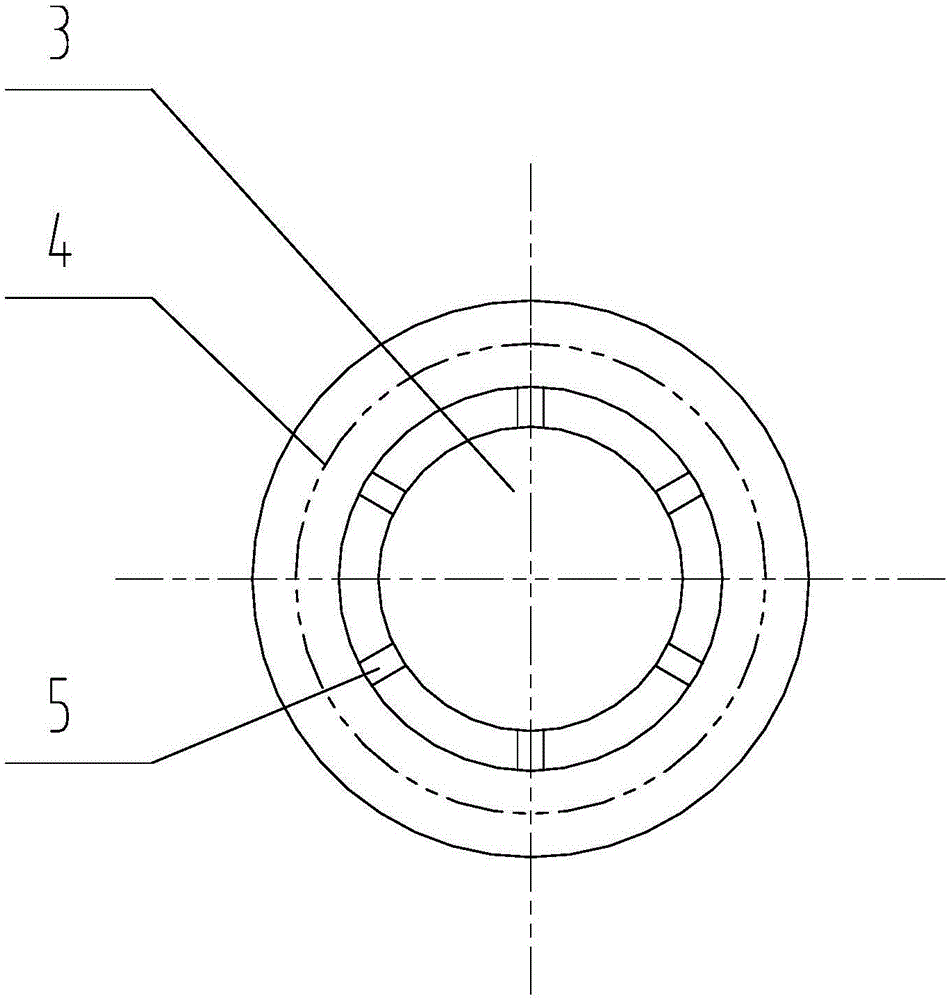

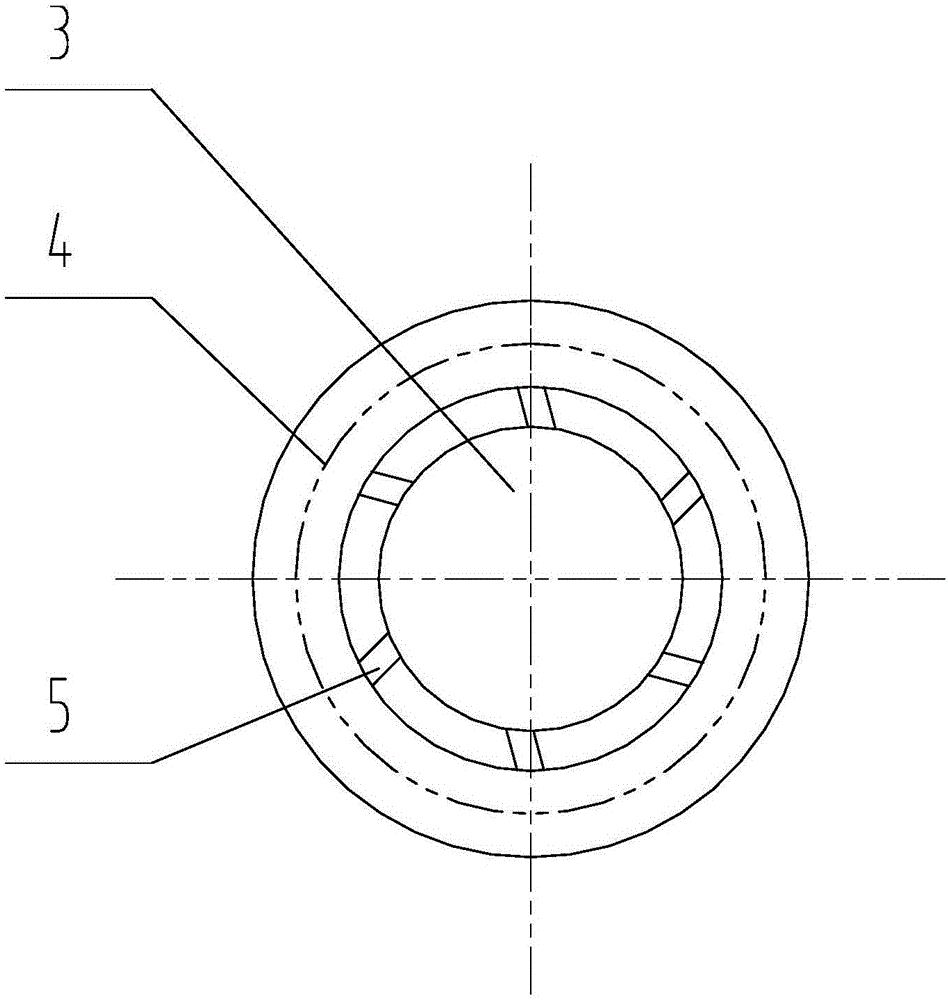

[0023] figure 1 Shown is a schematic structural view of the garbage and solid waste gasifier according to the first embodiment of the present invention. figure 2 shown as figure 1 Cross-sectional view of garbage, solid waste gasifier. See figure 1 , 2 , the garbage and solid waste gasifier of the present embodiment comprises: garbage and solid waste feed port 1, gas outlet 2, gasifier furnace body 3, the first gasification agent inlet header 4, the first gasification agent inlet Branch pipe 5, liquid slag discharge pipe 6, liquid slag discharge tank 7, second gasification agent inlet header 8, second gasification agent inlet branch pipe 9. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap