Automatic bottom thread changing control method of computer embroidery machine

A control method and technology for embroidery machines, which can be applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve problems such as a large number of human resources and affect the working efficiency of embroidery machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

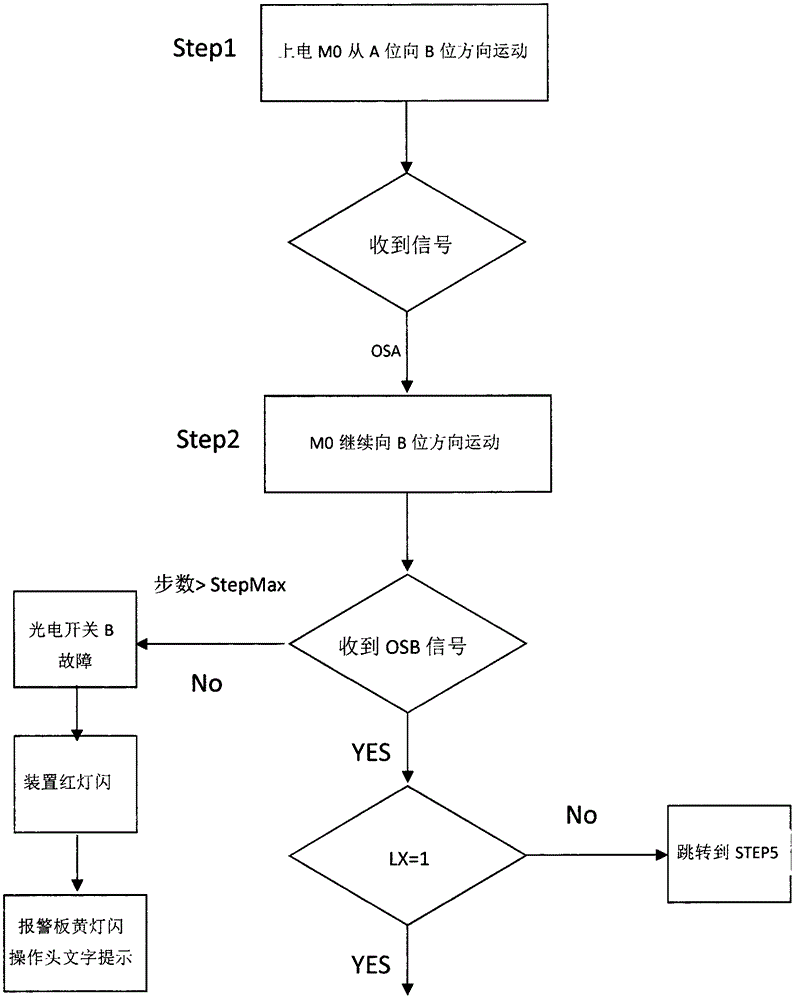

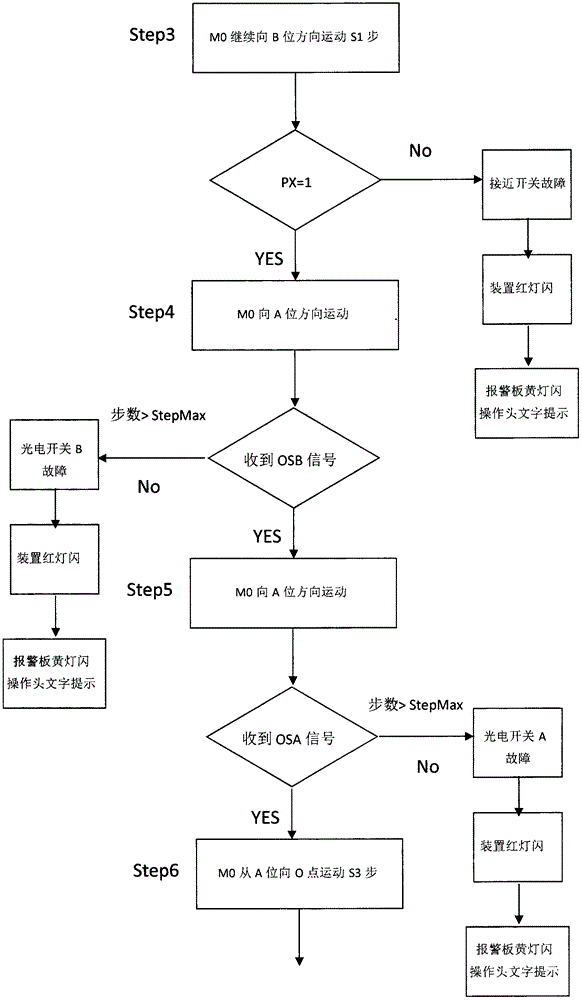

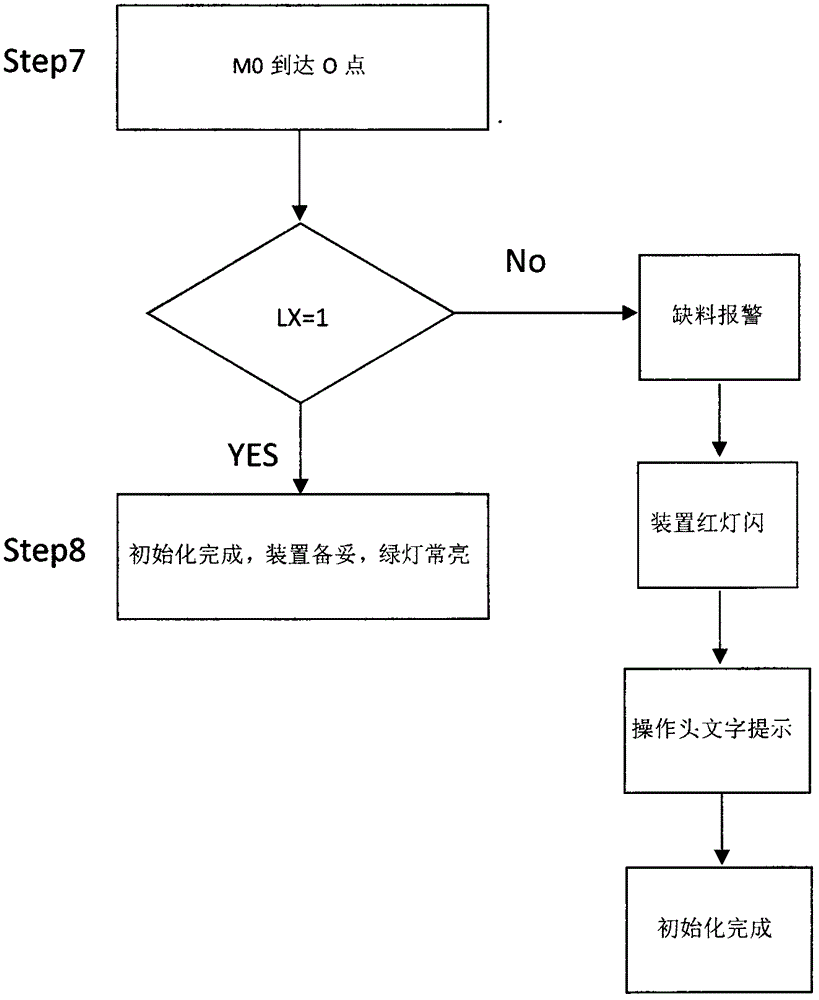

[0083] Such as Figure 1-14 Shown is a control method for automatic bobbin thread change of a computerized embroidery machine, which includes two parts: the first part is the initialization part, and the second part is the main program part

[0084] In the initialization part, after the automatic bobbin thread changing device is powered on, the stroke stepping motor moves from the rotary hook position to the spare bobbin case installation position. During this process, the photoelectric switch of the rotary hook position and the photoelectric switch of the spare bobbin case position feeds back the signal, and judges whether the sensor has fault; at the same time, use the signal of the spare bobbin case micro switch to judge whether the bobbin case has been installed in the spare position, and use the installed bobbin case to detect whether the proximity switch of the grabbing arm is faulty; judge the stroke step while detecting whether each sensor is faulty. Enter the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com