A timber frame-energy-dissipating brace anti-lateral force structural system

An energy-dissipating support and anti-lateral force technology, which is applied in the direction of building components, building structures, building types, etc., can solve the problems of increasing anti-lateral stiffness and difficult to balance anti-lateral stiffness and seismic performance, so as to improve lateral stiffness, Good deformation and energy dissipation capacity, small lateral deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

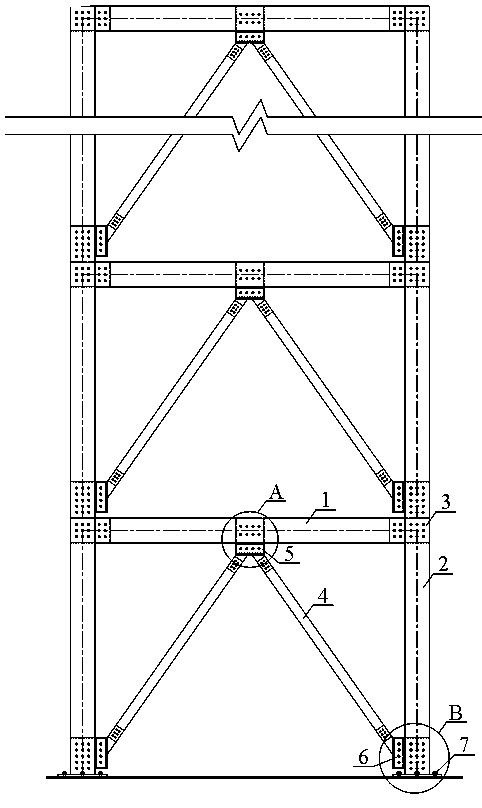

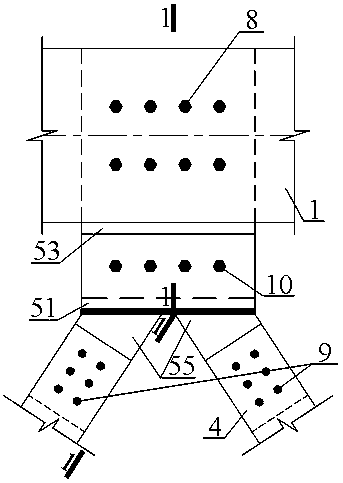

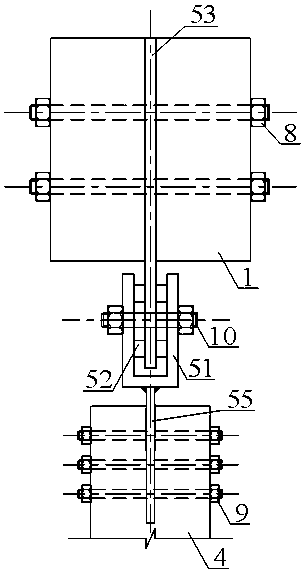

[0032] Example 1: If figure 1 As shown, a bamboo-wood frame-energy-dissipating support anti-lateral force structural system of the present invention can be used in a multi-layer bamboo-wood frame structure, and mainly includes wood (bamboo) beams 1, wood (bamboo) columns 2, and beam-column nodes 3. Wooden (bamboo) support 4. The first frictional damper 5. The second frictional damper 6. Column feet 7. The friction damper 5 is located between the wood (bamboo) support 4 and the wood (bamboo) beam 1, and the second friction damper 6 is located between the wood (bamboo) support 4 and the wood (bamboo) beam 1. ) between column 2. The wood (bamboo) beam 1 and the wood (bamboo) column 2, the wood (bamboo) support 4 and the first friction damper 5, the wood (bamboo) support 4 and the second friction damper 6, the first friction damper 5 and the wooden (bamboo) beam 1, the second friction damper 6, the wooden (bamboo) column 2 and the column foot 7 are connected by bolts.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com