Compressor performance testing device of multiple-evaporation-temperature system

A technology of testing device and evaporating temperature, applied in the field of compressors, can solve the problems of difference in working performance, complicated testing device, high input cost and testing cost, and achieve the effect of saving design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

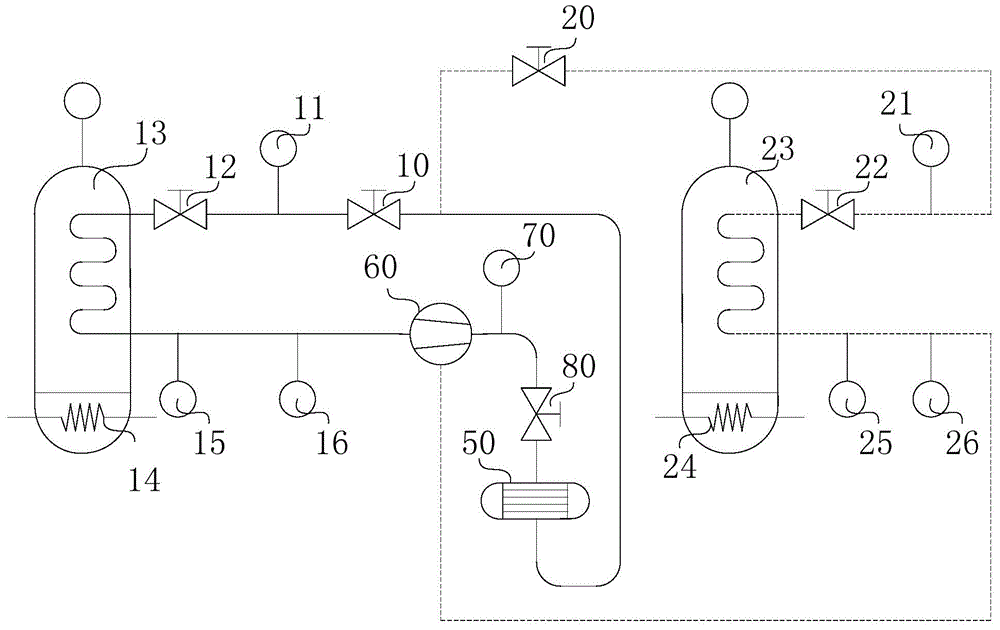

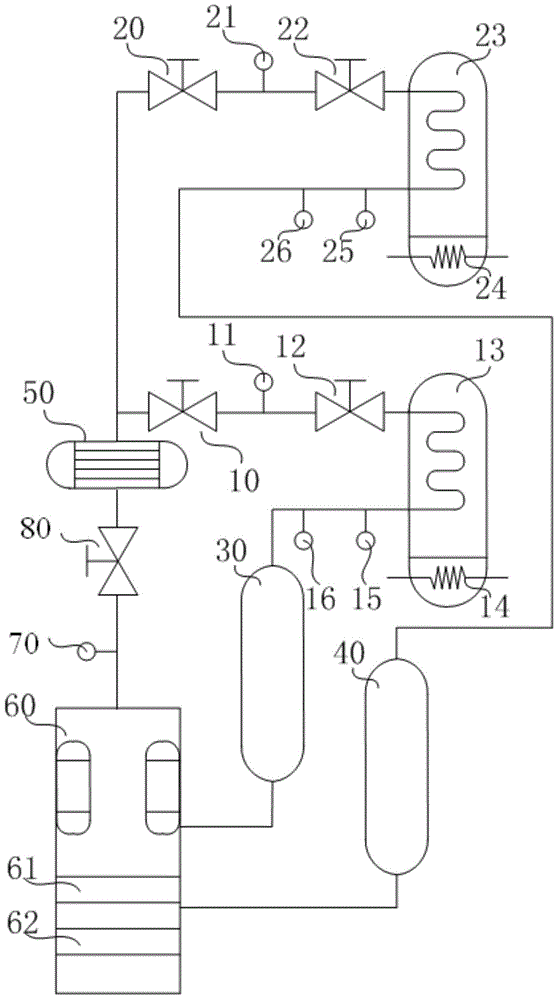

[0050] Such as figure 1 and 2 As shown, the multi-evaporation temperature system compressor performance testing device of the present invention is used for a compressor 60 with double cylinders and double liquid accumulators. The first cylinder 61 and the second cylinder 62 are connected in parallel, wherein the first cylinder 61 and the second cylinder 62 displacements can be the same or different. The first accumulator 30 communicates with the first cylinder 61 in the compressor 60, the second accumulator 40 communicates with the second cylinder 62 in the compressor 60, and the exhaust port of the compressor 60 passes through a pressure sensor 70 and a shut-off valve 80 is connected to condenser 50. The multi-evaporating temperature system compressor performance testing device of the present invention includes: a first refrigeration capacity test group and a second refrigeration capacity test group.

[0051]The first end of the first cooling capacity test group is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com