Shaft support structure and compressor

A technology of supporting structure and rotating shaft, which is applied in the field of compression, can solve problems such as crankshaft jamming, and achieve the effect of improving crankshaft jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

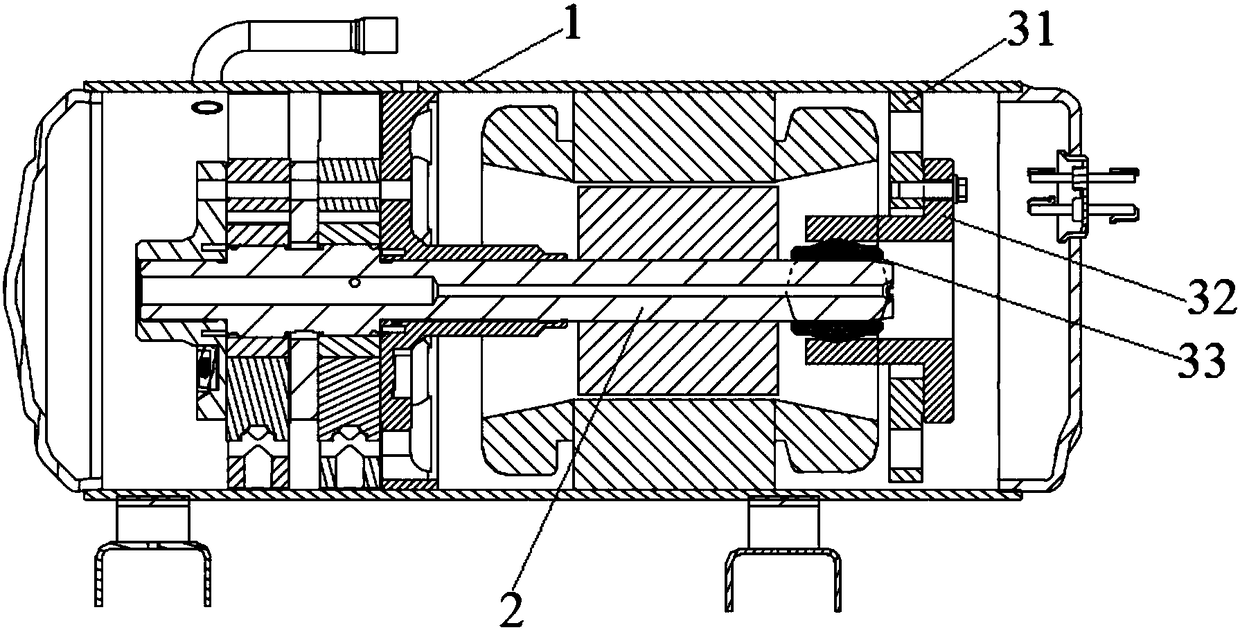

[0044] The following will be based on image 3 and Figure 4 The specific structure of the rotating shaft support structure of the first embodiment of the present invention will be described in detail.

[0045] Such as image 3 As shown, in the first embodiment, the rotating shaft support structure 3 includes a bracket 31 and a position compensation structure. The bracket 31 is fixedly arranged relative to the housing 1 . The rotating shaft 2 is rotatably supported on the bracket 31 . The rotating shaft supporting structure 3 also includes a bearing 32 . The bearing 32 is disposed on the bracket 31 . The bearing 32 is used to support the rotating shaft 2 . The position compensation structure is disposed between the bearing 32 and the rotating shaft 2 .

[0046] Preferably, as image 3 and Figure 4 As shown, the rotating shaft support structure 3 further includes a compensation sleeve 33 arranged between the bearing 32 and the rotating shaft 2 . The compensation slee...

no. 2 example

[0059] Such as Figure 5 As shown, in the second embodiment, the rotating shaft support structure 3 includes a bracket 31 and a position compensation structure. The bracket 31 is fixedly arranged relative to the housing 1 . The rotating shaft 2 is rotatably supported on the bracket 31 . The rotating shaft supporting structure 3 also includes a bearing 32 . The bearing 32 is disposed on the bracket 31 . The position compensation structure is arranged between the bracket 31 and the bearing 32 .

[0060] The bearing 32 includes a support portion for supporting the rotating shaft 2 and a flange connected to the support portion. The position compensation structure can be arranged between the bracket and the supporting part, or between the bracket 31 and the flange.

[0061] In this embodiment, the position compensation structure is arranged between the bracket 31 and the flange. Such as Figure 6 , Figure 7 and Figure 8 As shown, the first mating surface is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com