Reaction kettle leakage detection device

A detection device and reaction kettle technology, which is applied in the direction of measuring the increase and decrease rate of the fluid, using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of inability to accurately detect the leakage position of the device, time-consuming and laborious operation, and small detection position and other problems, to save operating time, ensure stability, and facilitate disassembly and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

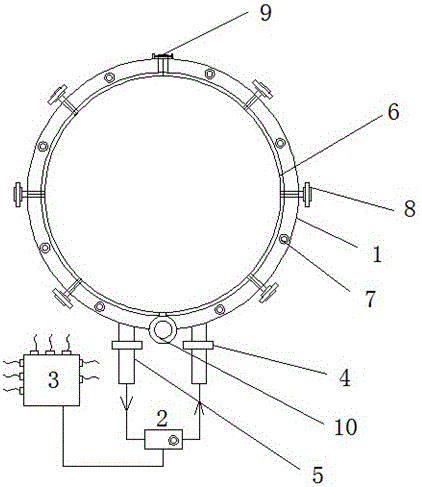

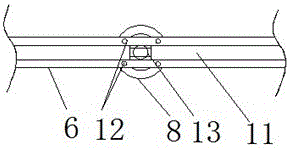

[0015] Embodiment 1: as figure 1 and 2 A reaction kettle leakage detection device is shown, the detection device is set on the shell of the reaction kettle, and the detection device includes: a ring detector 1, a circulating pressure water pump 2 and a control panel 3, the described The ring detector 1 is a ring-shaped shell, and the inside of the shell 1 is provided with a pressure water channel 11. The pressure water channel 11 is a pipe with a C-shaped cross section, and the inner side of the pressure water channel 11 is directly attached to the reactor. On the shell, the inner side of the shell 1 is provided with a ring-shaped sealing layer 6, the sealing layer 6 is set on the upper and lower sides of the pressure water channel 11, and the shell 1 is provided with a water inlet pipe 4 and a water outlet pipe 5, the said The water inlet pipe 4 and the water outlet pipe 5 are all connected to the circulating pressure water pump 2, and a plurality of pressure detection probe...

Embodiment 2

[0016] Embodiment 2: as figure 1 and 2 As shown, the ring detector housing 1 is composed of two semicircular pipes of the same size, one end of the two semicircular pipes is connected to each other through a rotating shaft 10, and one end is connected to each other through a lock nut 9; The ring detector housing 1 installed in combination facilitates the disassembly and fixing of the ring detector and saves the operating time of the detection work.

Embodiment 3

[0017] Embodiment 3: as figure 1 and 2 As shown, the water inlet pipe 4 and the water outlet pipe 5 are respectively connected to two semicircular pipes; during the detection process of this device, water with a certain pressure is passed into the ring detector 1 to ensure that the overall detector 1 The water pressure at each position is uniform, and the water flow must pass into one end of the two semicircular pipes and discharge from the other end to complete the uniform control of the pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com