Dynamic-seal-free quick open type testing method for material fatigue properties in high-pressure hydrogen environment

A test method and fatigue performance technology, applied in the field of quick-opening high-pressure hydrogen environment material fatigue performance test, can solve the problems of lack of structural design, low reliability, large quick-opening structure, etc., to eliminate hydrogen leakage and frictional power consumption, The effect of ensuring the safety of personnel and equipment and increasing the frequency of test loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

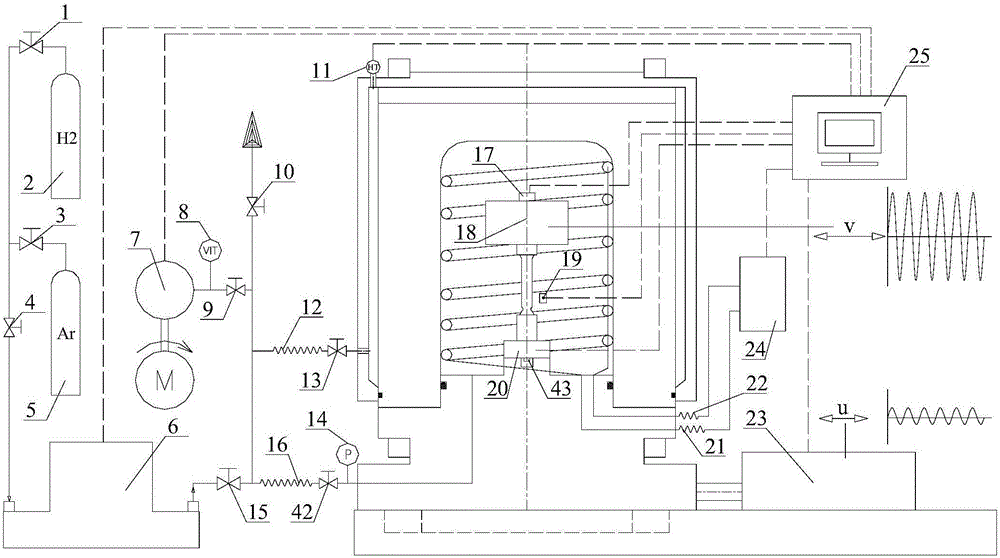

[0052] Such as figure 2 As shown, the non-moving sealed quick-open high-pressure hydrogen environment material fatigue performance test device used in this example includes an environmental box module, a gas source module, a supercharger 6, a vacuum pump 7, a heat exchange module and an industrial computer 25.

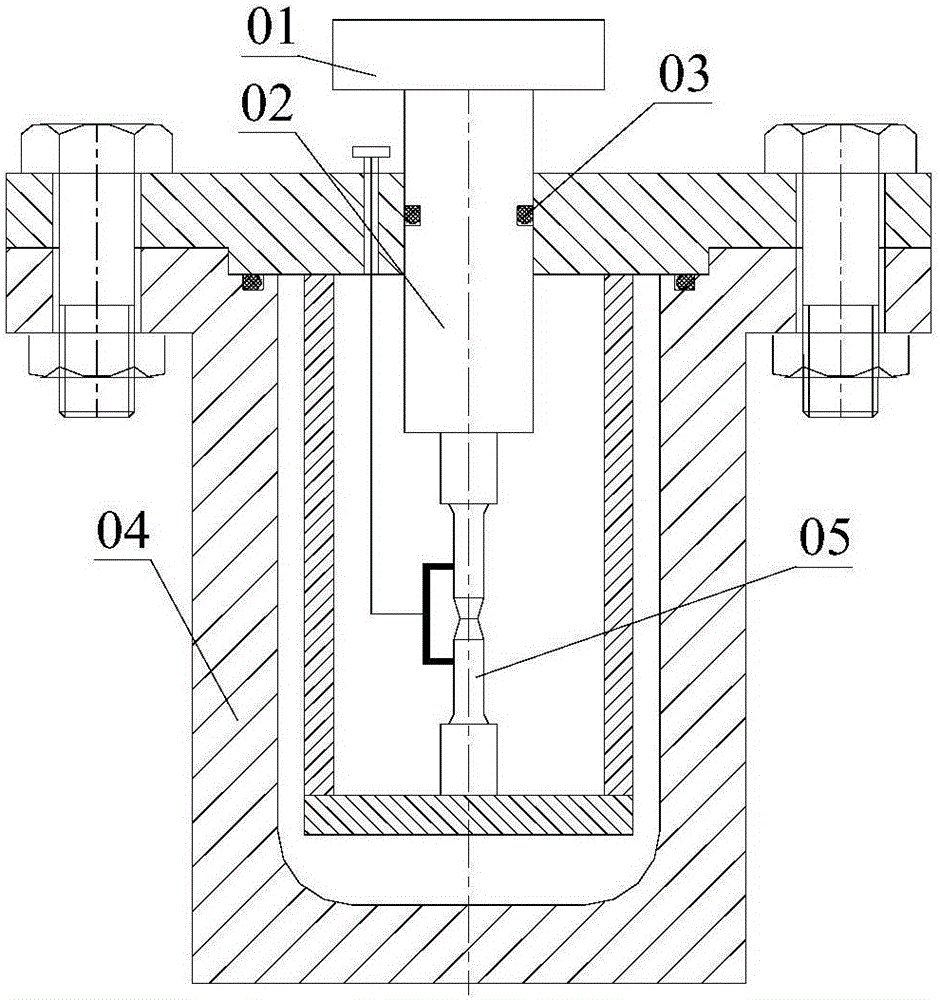

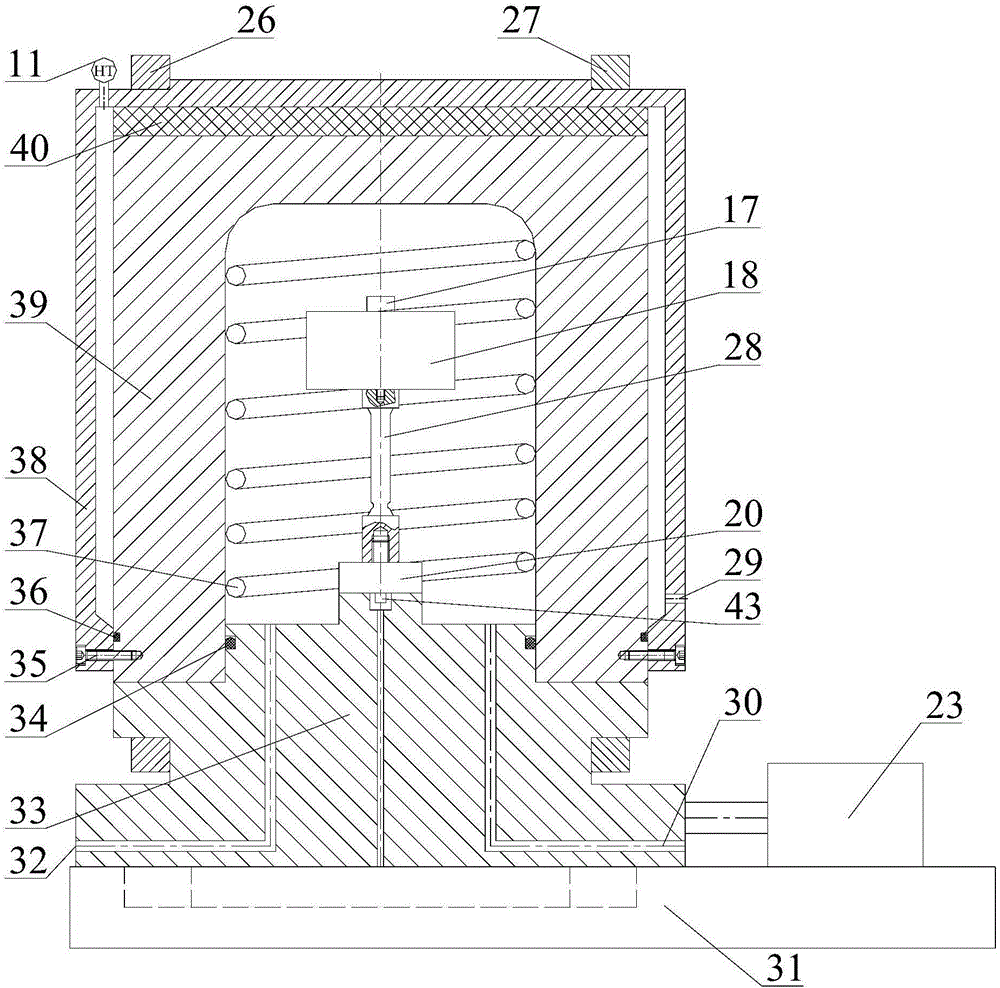

[0053] Such as image 3 and Figure 4 As shown, the environmental chamber module consists of an environmental chamber top cover, an environmental chamber bottom cover 33, a left rectangular pressure frame 26, a right rectangular pressure frame 27, a heat exchange elbow 37, an acceleration sensor 17, an acceleration sensor 43, a weight 18, a load The sensor 20, the base 31 and the exciter 23 are composed; the top cover of the environmental box includes a cylinder body 39, a jacket 38 and a heat-insulating ceramic plate 40, and the top of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com