Blue light-filtering optical film and manufacturing method thereof

An optical film and manufacturing method technology, applied in optics, optical components, instruments, etc., can solve the problems of reduced light transmittance, product power consumption, limited anti-glare effect, etc., and achieve the effect of reducing glare and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

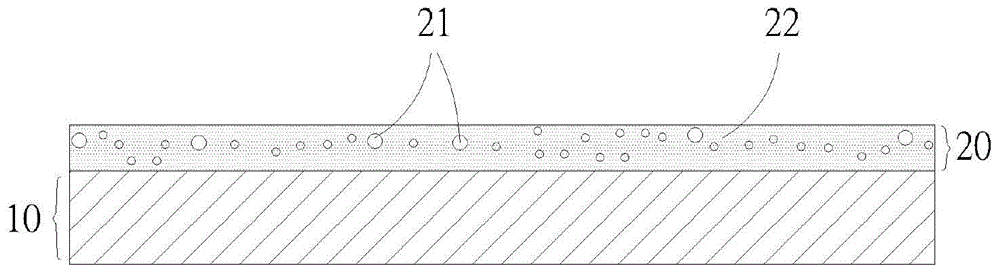

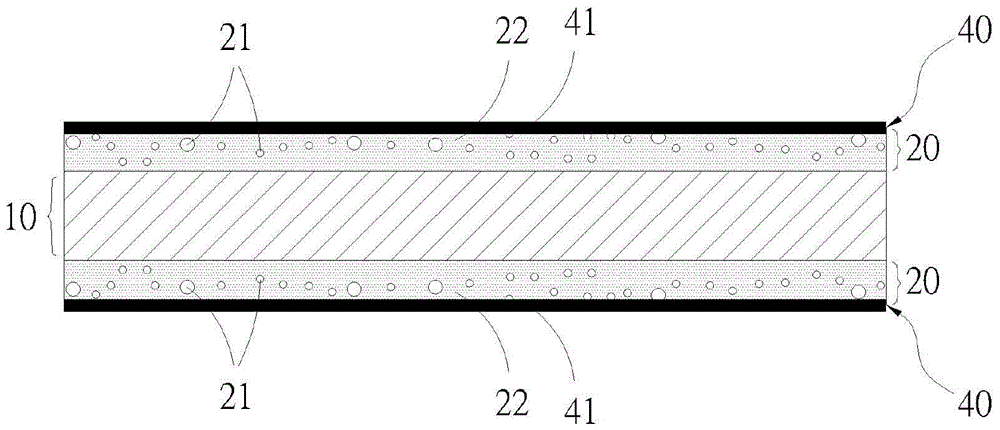

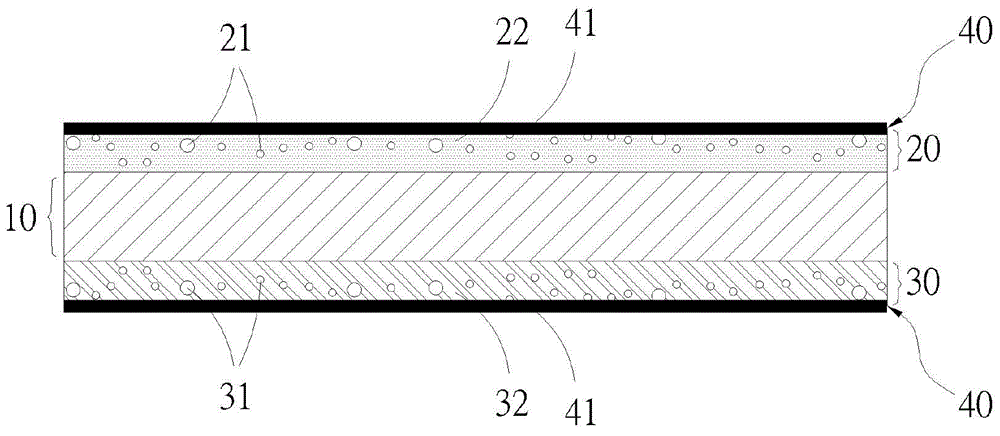

[0040] The present invention mainly provides an optical film for filtering blue light that can effectively reduce glare and has better structural strength, and a method for manufacturing the optical film for filtering blue light related to it. The optical film for filtering blue light of the present invention can have the following properties: Figure 1 to Figure 3 Several basic structural types shown in figure 1 In the first basic structural form shown, the optical film for filtering blue light of the present invention includes: a transparent base material 10, which is a material with preset toughness, tensile strength, impact strength and wear resistance. Thermoplastic polyester; during implementation, the transparent substrate 10 may be hardened and molded from polyethylene terephthalate (PET).

[0041] A diffusion film 20, covering any side of the transparent substrate 10, is a transparent film that is hardened and shaped by the resin solid content 22 (also called solid co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com