Hexagonal phase epitaxial cadmium sulfide on copper indium gallium selenide for a photovoltaic junction

一种硒化铜铟镓、硫化镉的技术,应用在光伏发电、电气元件、气候可持续性等方向,能够解决化学浴沉积方法整合、不是可行等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

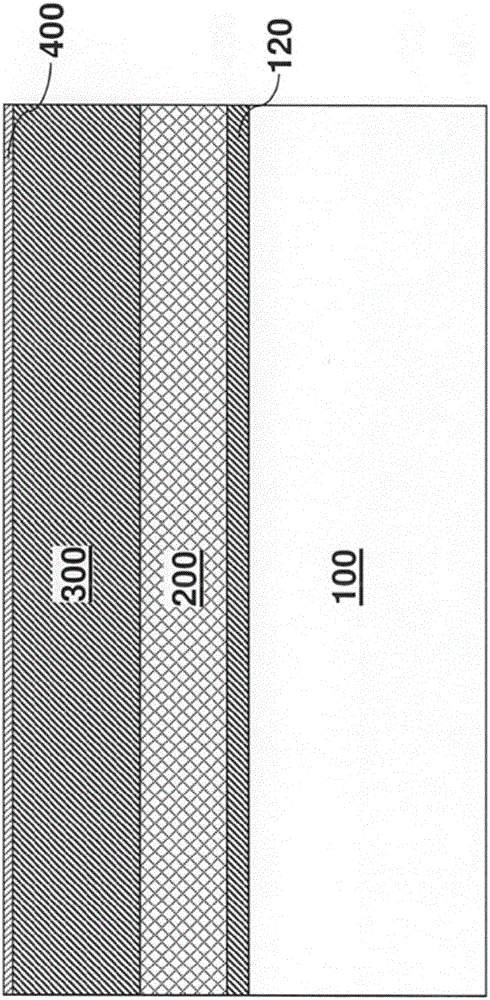

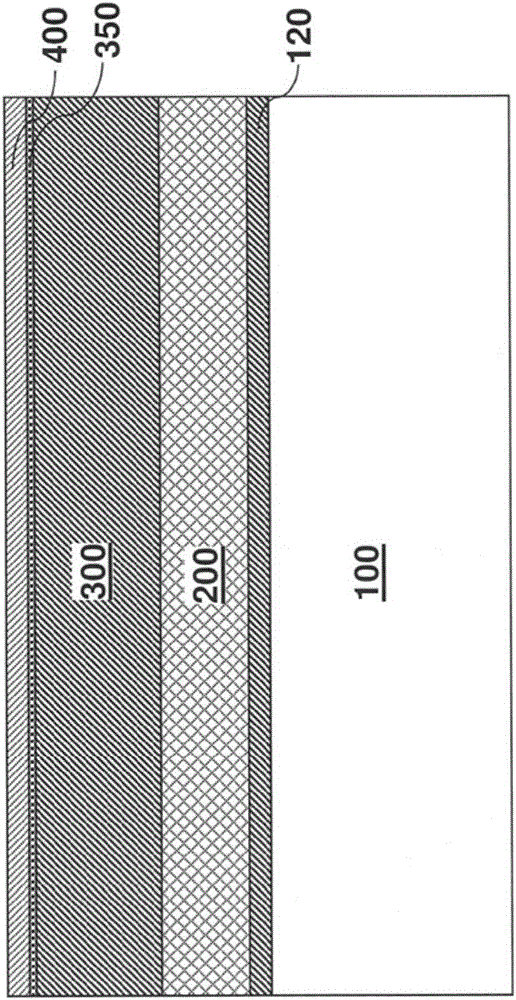

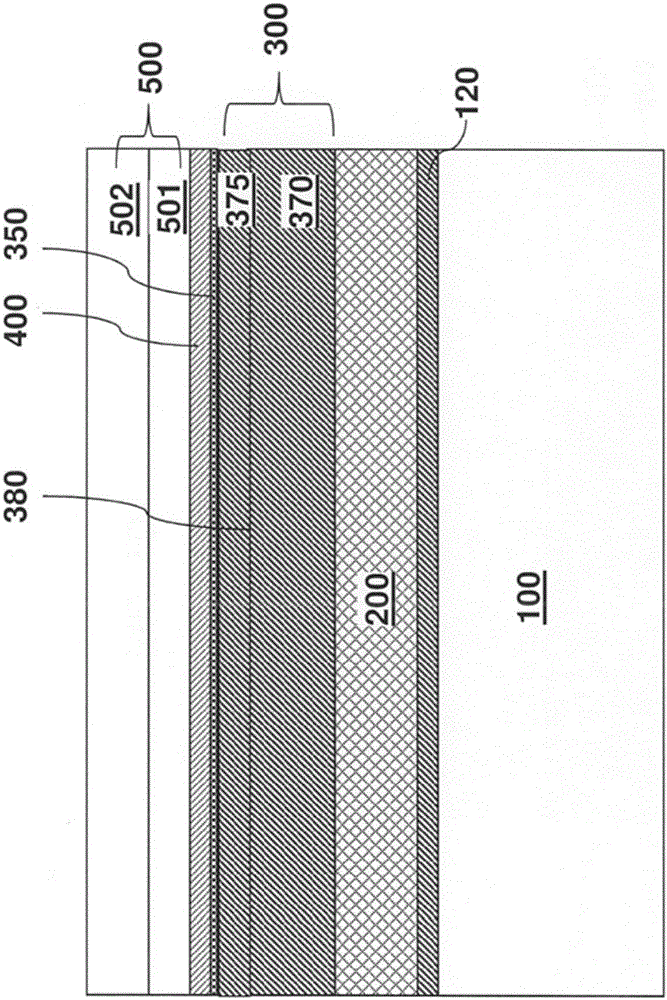

Image

Examples

example

[0115] By using advanced scanning transmission electron microscopy (STEM) combined with energy dispersive X-ray spectroscopy (EDS), the present inventors systematically investigated the simultaneous transfer of hydrogen and oxygen by magnetron sputtering on moving substrates as described above. Both were introduced into several different PVD-CdS / CIGS heterojunctions fabricated in the processing chamber. The main difference in heterojunctions is the different oxygen content used in the sputtering gas during the PVD cadmium sulfide deposition process.

[0116] Table I shows that in CdS process with different O 2 Performance of measurements of four different CdS / CIGS devices in concentrations. G19 (with highest O 2 ) delivered the lowest efficiency, while G21 (without O 2 ) show better performance. O in CdS 2 With an increase, device performance gradually improved as seen in the G20 and G25 devices before decreasing at the highest level. This suggests that the moderate inco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com